Converting a corn head row unit for harvesting corn stalks in addition to ears

a corn head and corn head technology, applied in the field of corn head row unit conversion, can solve the problems of inconvenient corn harvesting and substantial additional cost of corn head addition,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

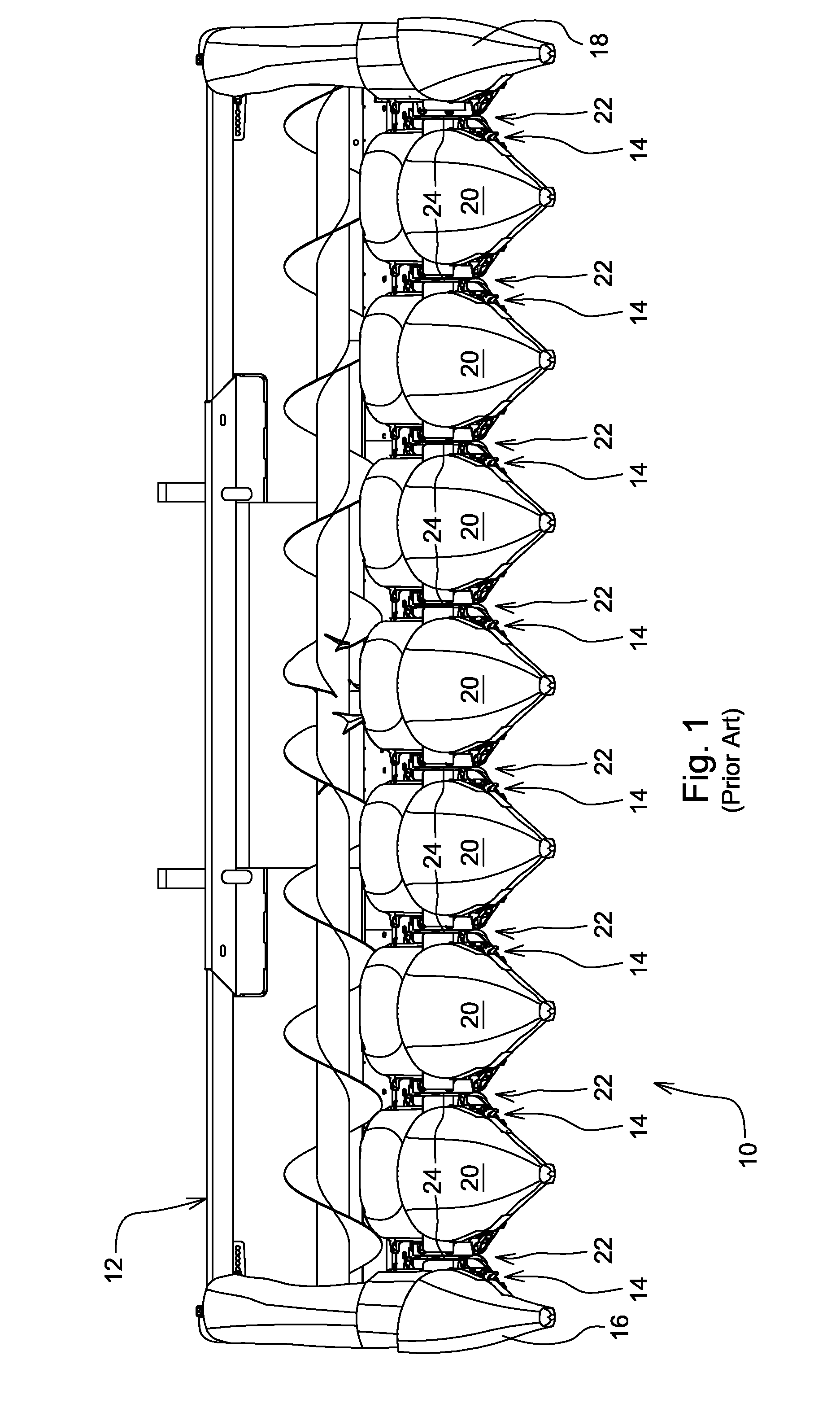

[0017]Referring now to FIG. 1, there is shown a corn head 10 including a transversely extending frame 12 across the width of which is attached a plurality of forwardly projecting row units 14 spaced in side-by-side relationship to each other a distance commensurate with that of the spacing between adjacent rows of corn to be harvested, with it being noted that it is conventional to mount the row units 14 for transverse adjustment in order to accommodate various corn row spacings. Mounted to the row units 14 and serving to separate comingled stalks of adjacent rows from one another are crop dividers including right and left dividers 16 and 18, respectively, at the opposite ends of the corn head 10, and seven identical central dividers 20, with the crop dividers defining longitudinal passages 22 between them which are centered relative to rows to be harvested and relative to a central fore-and-aft extending relatively narrow throat 24 defined by each row unit 14, as described below in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com