Biogas residue humus pot, and preparation method and application of biogas residue humus pot

A nutrient bowl and biogas residue technology, which is applied in the field of waste treatment technology and crop seedling raising, can solve the problems of time-consuming preparation of fermented straw residue raw materials, complicated preparation of outer core structure, etc., and achieves widening the scope of utilization materials, improving fertilizer efficiency and organic matter Content, nutrient-rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

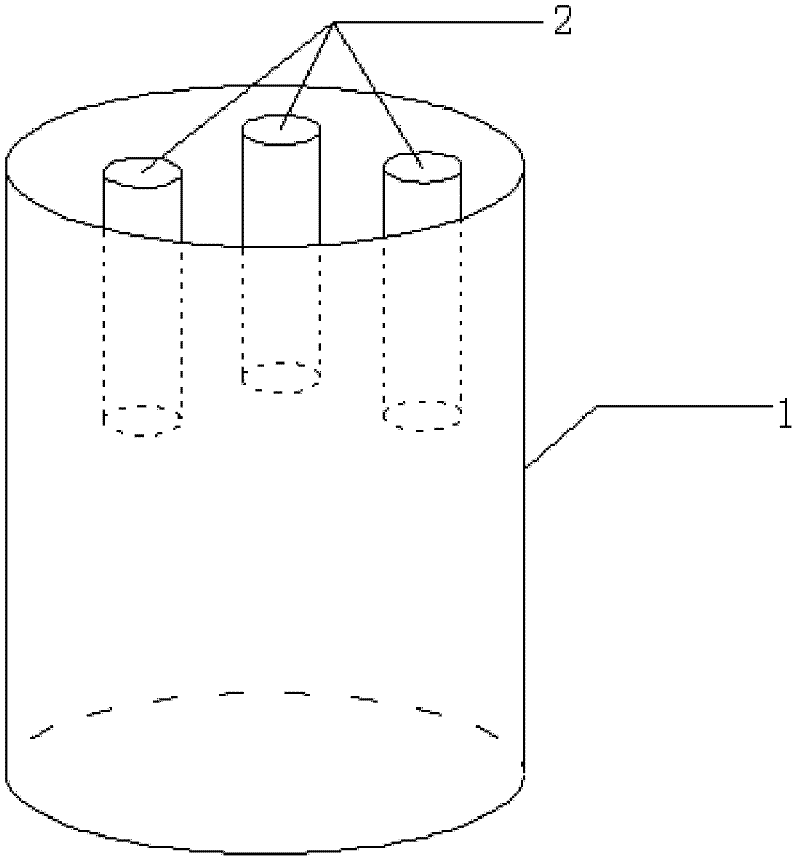

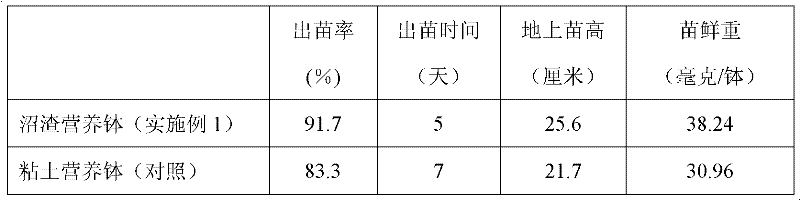

[0046] Example 1: Biogas residue nutrition pot suitable for small seeds with relatively small nutritional requirements for seed germination and growth

[0047] Biogas residue nutrition bowl, the raw material components are as follows:

[0048] Fresh biogas residue 625g; clay 1010g; cottonseed hull 70g;

[0049] The biogas residue nutrition pot is a cylindrical block with 3 sowing holes in the middle. The depth of the sowing hole is 1 / 2 of the height of the cylinder nutrition bowl.

[0050] The depth of described sowing hole is 6cm, and diameter is 3cm.

[0051] Prepare as follows:

[0052] Mix fresh biogas residue, clay, and cottonseed hull materials according to the ratio, and stir evenly to obtain a mixed material; put the mixed material into a nutrition bowl mold, press manually or mechanically, and press it into a block shape with a seeding hole in the middle; then demould, and dry naturally After 2-8 days or drying, the biogas residue nutrition bowl is obtained.

[0...

Embodiment 2

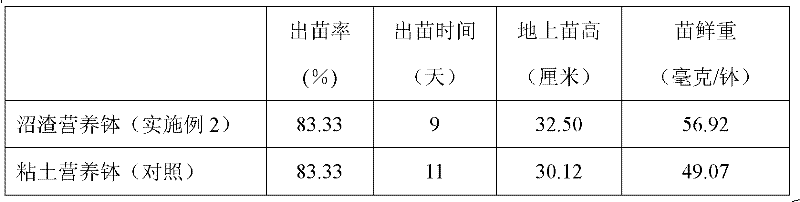

[0057] Example 2: Biogas residue nutrition pot suitable for large seeds with relatively large nutritional requirements for seed germination and growth

[0058] The preparation method is the same as in Example 1, except that the raw material components are as follows:

[0059] Fresh biogas residue 1250g; clay 505g; cottonseed hull 30g

[0060] The biogas residue nutrition pot is a cylindrical block with 4 sowing holes in the middle. The cylinder block is 12 cm high, the depth of the seeding hole is 5 cm, and the diameter is 2 cm.

[0061] The preparation method is the same as that in Example 1, and the mold used for the preparation of the biogas residue nutritional bowl is adapted to the shape and structure of the biogas residue nutritional bowl.

Embodiment 3

[0062] Example 3: Biogas residue nutrition pot suitable for large seeds with relatively large nutritional requirements for seed germination and growth

[0063] The preparation method is the same as in Example 1, except that the raw material components are as follows:

[0064] Fresh biogas residue 1250g; clay 505g; corn straw 58g

[0065] The biogas residue nutrition bowl is a cube block with 2 sowing holes in the middle. The length, width and height of the cube are 10cm, the depth of the seeding hole is 6cm, and the diameter is 3cm.

[0066] The preparation method is the same as that in Example 1, and the mold used for the preparation of the biogas residue nutritional bowl is adapted to the shape and structure of the biogas residue nutritional bowl.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com