Intelligent paving machine

A technology of intelligent paving and intelligent machinery, applied in the direction of construction and building structure, can solve the problems of low bonding rate between floor tiles and their underlying adhesive layers, unevenness, uneven gap between floor tiles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

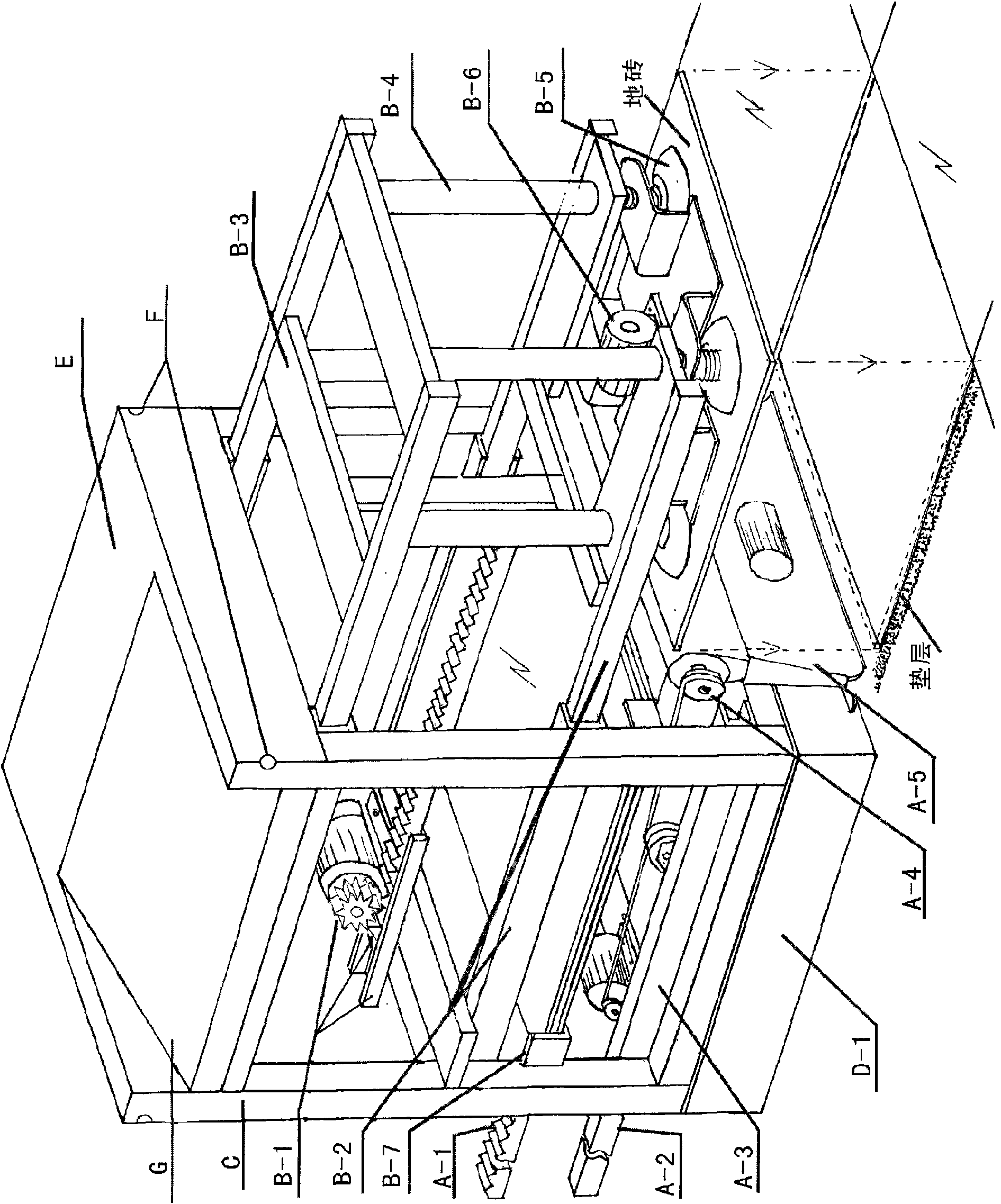

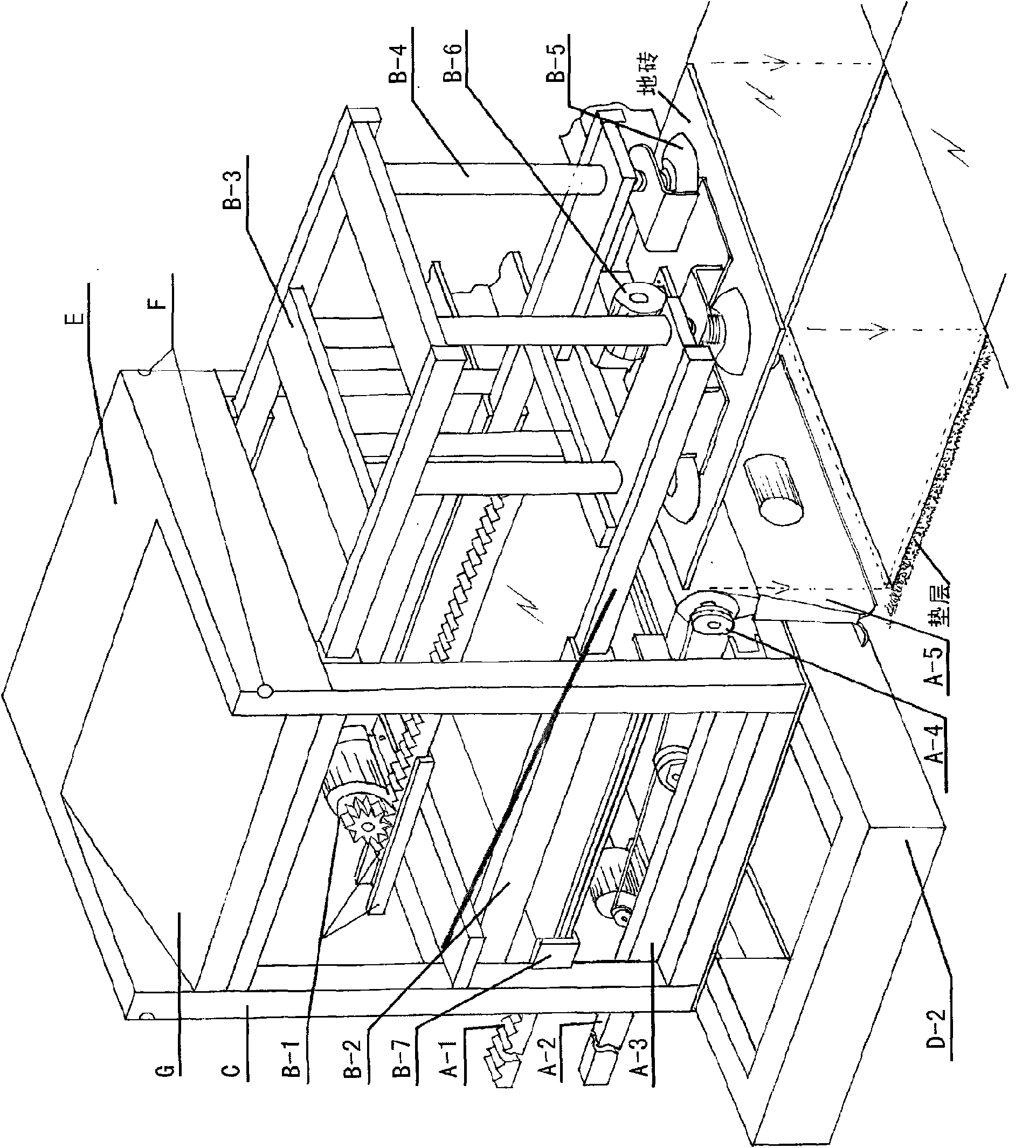

[0044] Depend on figure 1 It can be seen that the trackless intelligent brick laying machine has the characteristics of small size, strong mobility, convenient use, less difficulty in development and manufacturing, and lower cost, so the model is the preferred implementation plan. The following is a detailed description of the program implementation.

[0045] figure 1 The shown component E is a computer program control device of the trackless intelligent brick laying machine. The software used is compiled according to the technical requirements of floor tile laying and the characteristics of mechanical operations. All the operating procedures of the machine are controlled by computers.

[0046] figure 1 The shown part F is the detection device of the trackless intelligent brick laying machine. The device is set at the upper end of the four corners of the main engine structure frame and at the same height. It is a device that detects the three-dimensional coordinate marks s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com