System and method suitable for quality control of reverse solidification technique

A technology of reverse solidification and quality, which is applied in the fields of casting production, intelligent control and computer information processing, can solve problems such as single functionality, achieve the effects of improving bonding quality, speeding up research progress, and saving experiment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0074] The following examples illustrate the knowledge expression of the knowledge base, the process parameter reasoning module, the defect diagnosis reasoning module, and the rule adaptive correction module reasoning rule expression.

[0075] 1. Knowledge expression of the knowledge base

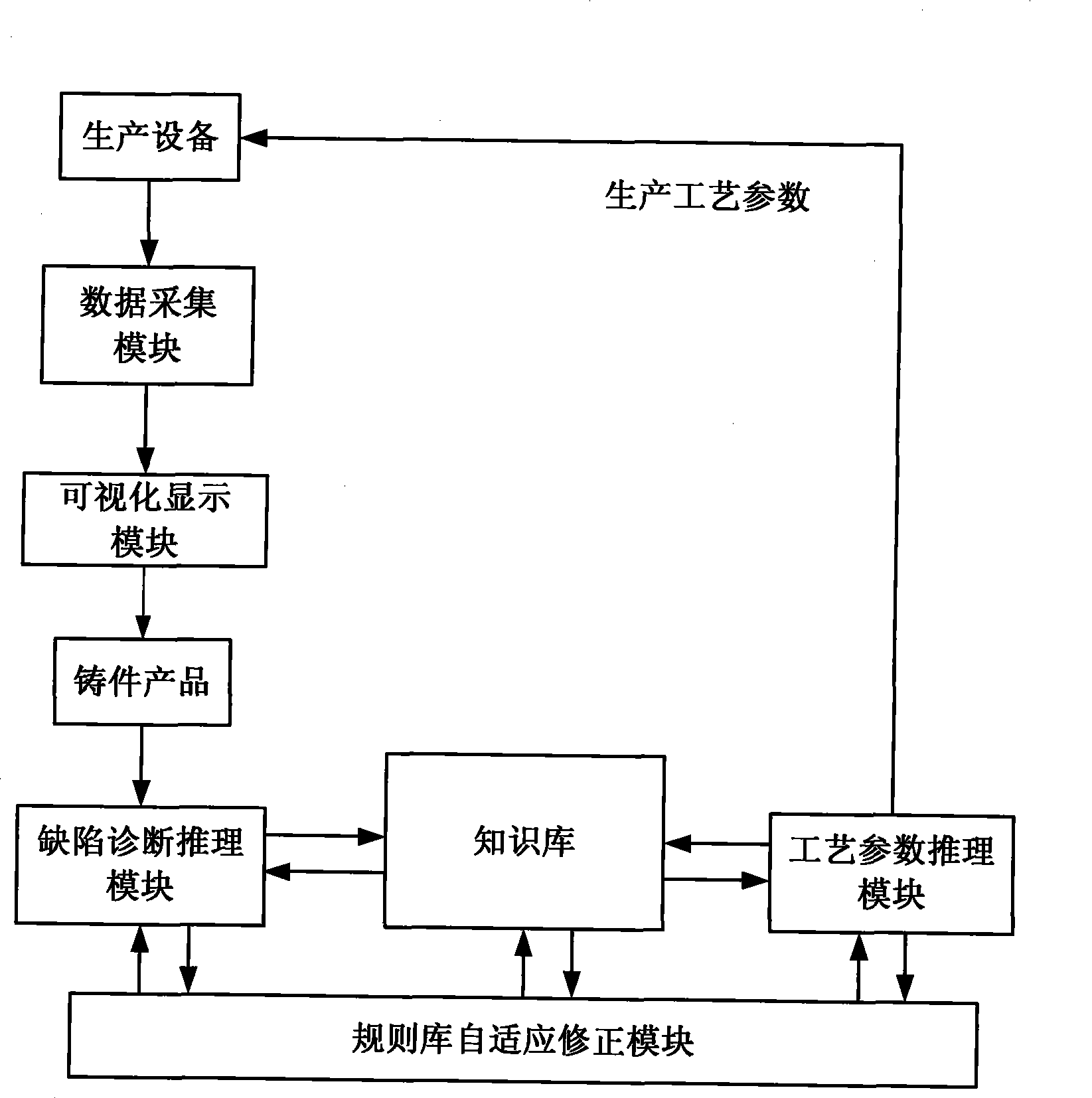

[0076] Because most of the knowledge types in the inverse solidification process belong to various narrative knowledge related to the description of the problem state, including various state descriptions and constraint conditions, attached figure 1 The knowledge expression method in the shown knowledge base adopts the rule-based production knowledge and expression method, namely:

[0077] RN: IF M THEN N WITH CF(N, M)

[0078] In the formula, RN is the rule number, M is the precondition of the rule, N is the conclusion drawn by the condition, and CF is the confidence factor of the rule.

[0079] The confidence factor indicates the degree of support of evidence M to N, and the value range is [...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com