Preparation method of waterborne resin and water-based paint composite

A water-based resin, water-based technology, applied in the field of coatings, can solve the problem that the hardness, water resistance and wear resistance of water-based coatings cannot be met at the same time, and achieve the effect of excellent anti-aging performance, good wear resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

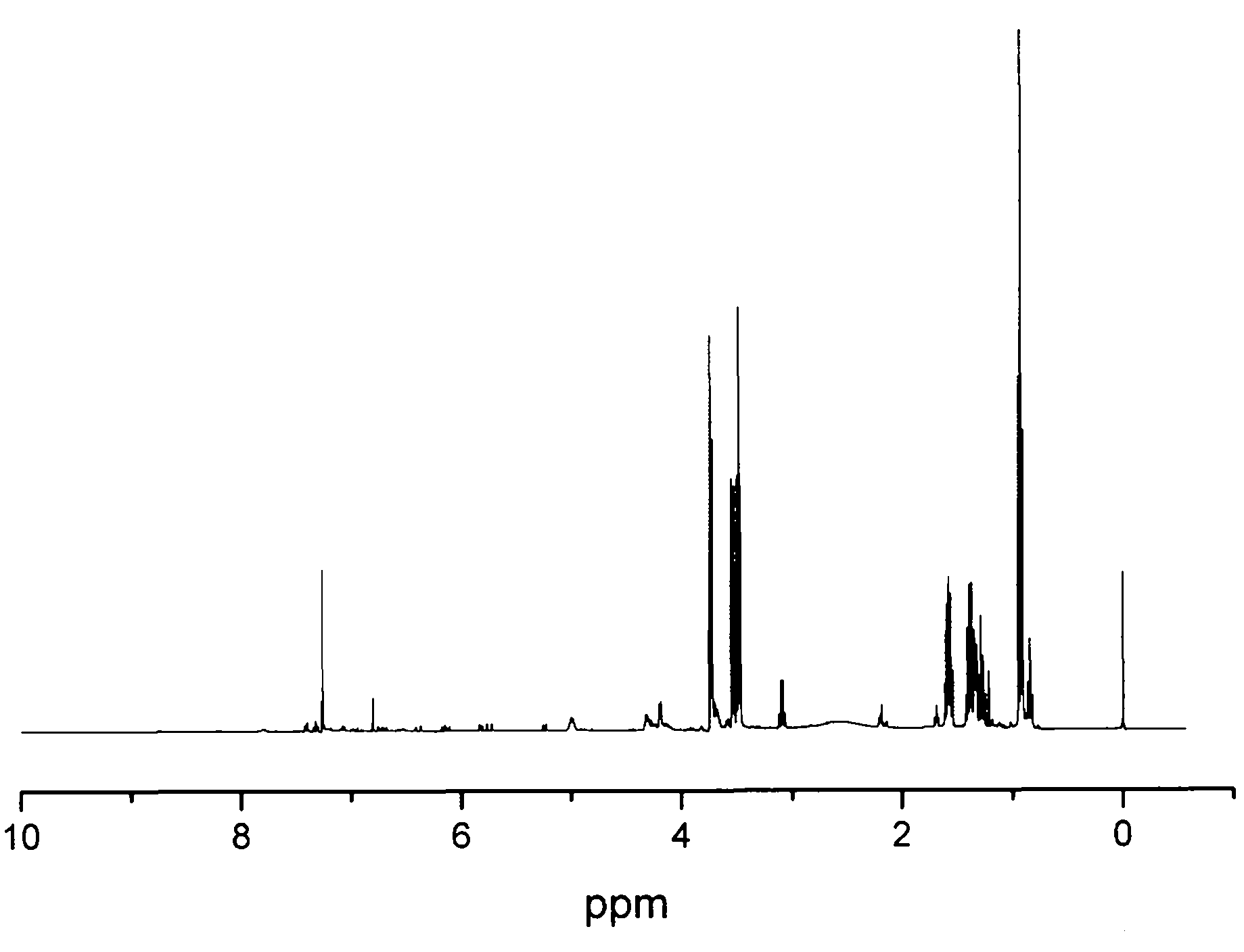

Image

Examples

preparation example Construction

[0030] The invention discloses a preparation method of water-based resin, comprising the following steps:

[0031] Step a) under the protection of nitrogen, the first monomer, the second monomer, the catalyst and the antioxidant are mixed and reacted to obtain the first product, and the first monomer is trimethylolpropane and neopentyl glycol, The second monomer includes isophthalic acid, isophthalic acid-5-sodium sulfonate and diacid monomers, and the diacid monomers are butenedioic acid and / or glutaconedic acid;

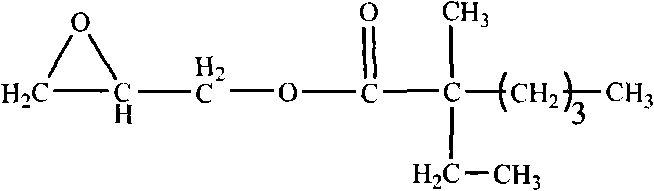

[0032] Step b) Under the protection of nitrogen, the aqueous co-solvent, the third monomer, γ-glycidyl ether propyl trimethoxysilane, free radical initiator, chain transfer agent and the first product are mixed and reacted to obtain the second Second product, the third monomer is glycidyl tertiary carbonic acid ester and functional monomer, and the functional monomer is one of methacrylic acid, isobornyl methacrylate, glycidyl methacrylate and styrene or several; ...

Embodiment 1

[0057] Preparation of water-based resin P1

[0058] According to the formula quantity shown in table 1, prepare according to the following method:

[0059] Step a) According to the formula amount of P1 in Table 1, add the first monomer, the second Dimonomer, catalyst, antioxidant, reflux dehydration, then heat up to 220°C at a heating rate of 10°C / 20min, keep warm and reflux for 3 hours, then depressurize for 2 hours, and cool down to 60°C to obtain the first product;

[0060] Step b) adding the water-based co-solvent into a four-necked flask equipped with a stirrer, a condenser, a thermometer and an oil bath heating device, adding the first product, and then adding glycidyl tertiary carbonate E10P and a siloxane coupling agent, Under the protection of nitrogen, raise the temperature to 138-142°C, add the functional monomer, add the free radical initiator in 3 times, then react for 3 hours, add the chain transfer agent and continue the reaction for 1 hour to obtain the second...

Embodiment 2~5

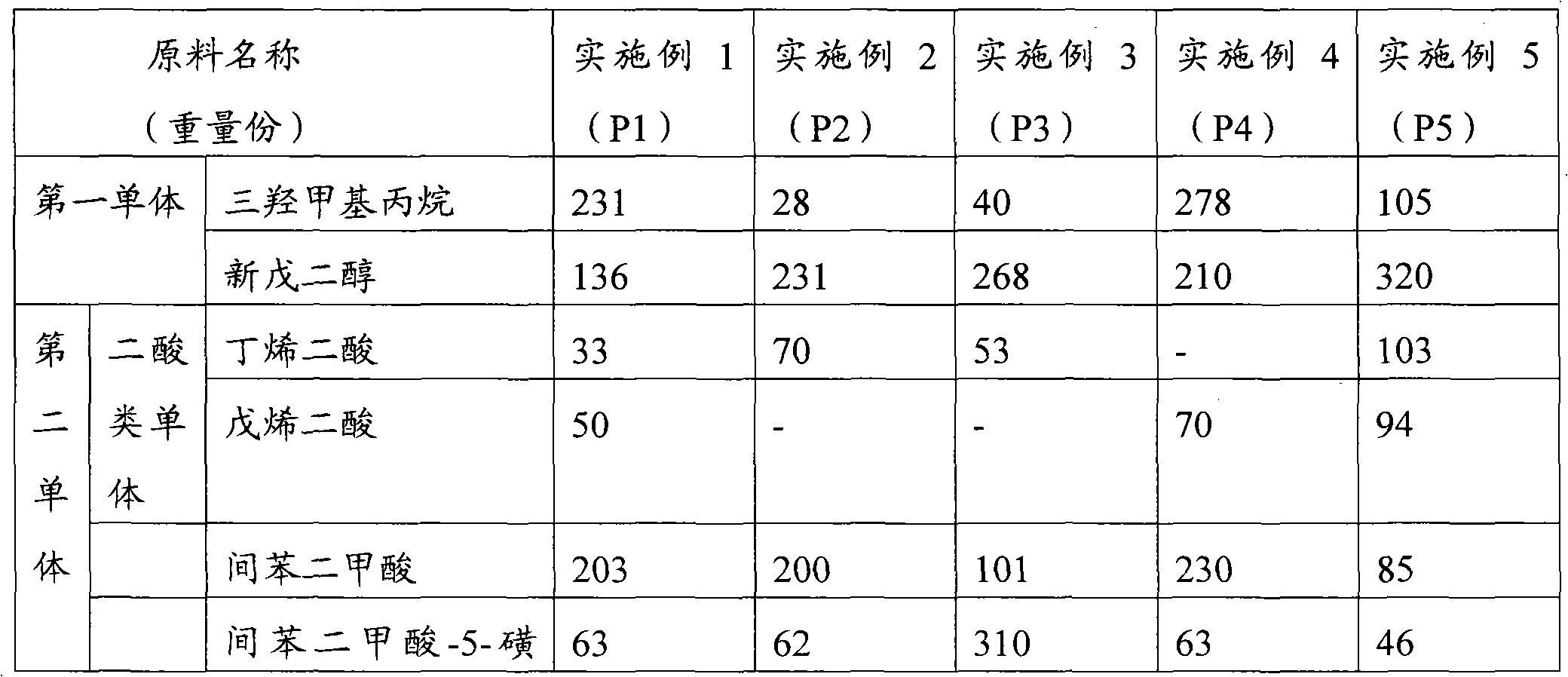

[0064] The preparation process of water-based resins P2-P5 is the same as in Example 1, and the specific process parameters are shown in Table 1.

[0065] Table 1 The raw material weight ratio formula of the water-based resin prepared in Examples 1-5

[0066]

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com