Inflaming retarding thermoplastic polyurethane elastic body

A thermoplastic polyurethane and elastomer technology, applied in the field of flame retardant thermoplastic polyurethane elastomer, can solve the problems of poor comprehensive performance and reduce mechanical properties such as tensile strength elongation at break, etc., to achieve good mechanical properties, good wear resistance, The effect of high tensile strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

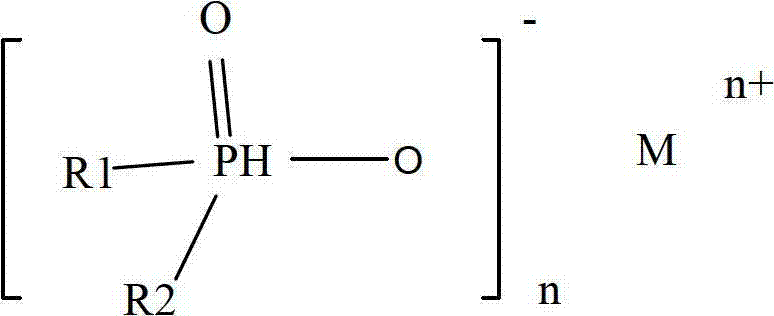

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with embodiment the present invention is described in further detail.

[0033] The production process of the samples of the embodiment of the invention and the comparative example required for the test is as follows: first, the raw materials are melted and kneaded by a twin-screw extruder, and then the melted output from the die head of the extruder is cooled through a cooling tank , and finally made into pellets of flame-retardant thermoplastic polyurethane elastomer. The prepared flame-retardant thermoplastic polyurethane elastomer pellets were injection-molded using an injection molding machine, and fully stabilized at room temperature to finally obtain a sample to be tested, and various performance tests were performed.

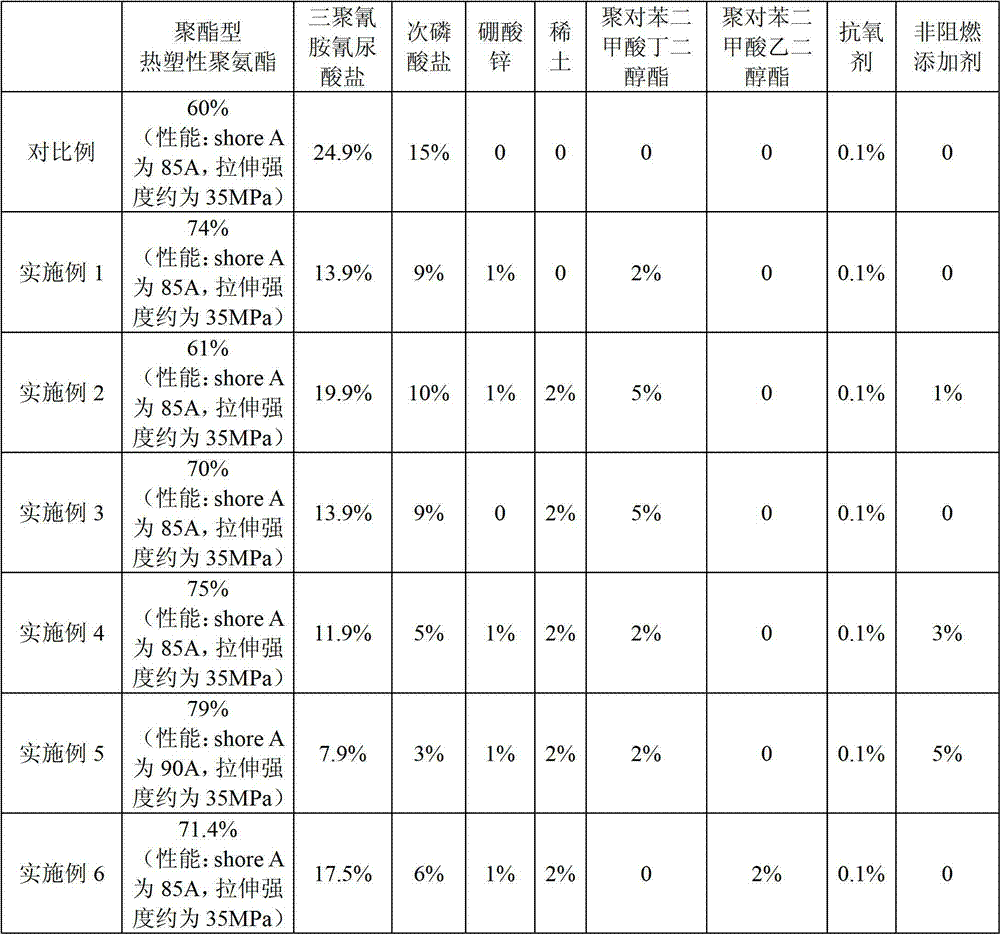

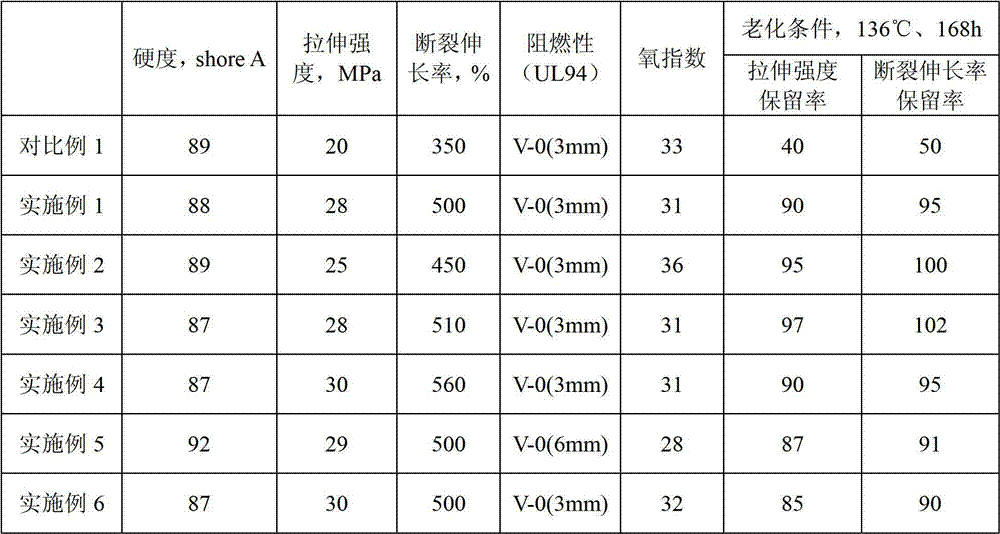

[0034] See Table 1 below for the proportions by weight of the Examples and Comparative Examples, and Table 2 below for their properties and comparative results.

[0035] Table 1: The weight percent proportioning of embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com