Conductive adhesive added with short rod type nano silver powder and preparation method thereof

A technology of nano-silver powder and conductive adhesive, applied in conductive adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of high price of silver conductive adhesives, low connection strength, and impact on service life, etc. Achieve excellent anti-aging performance, low cost, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

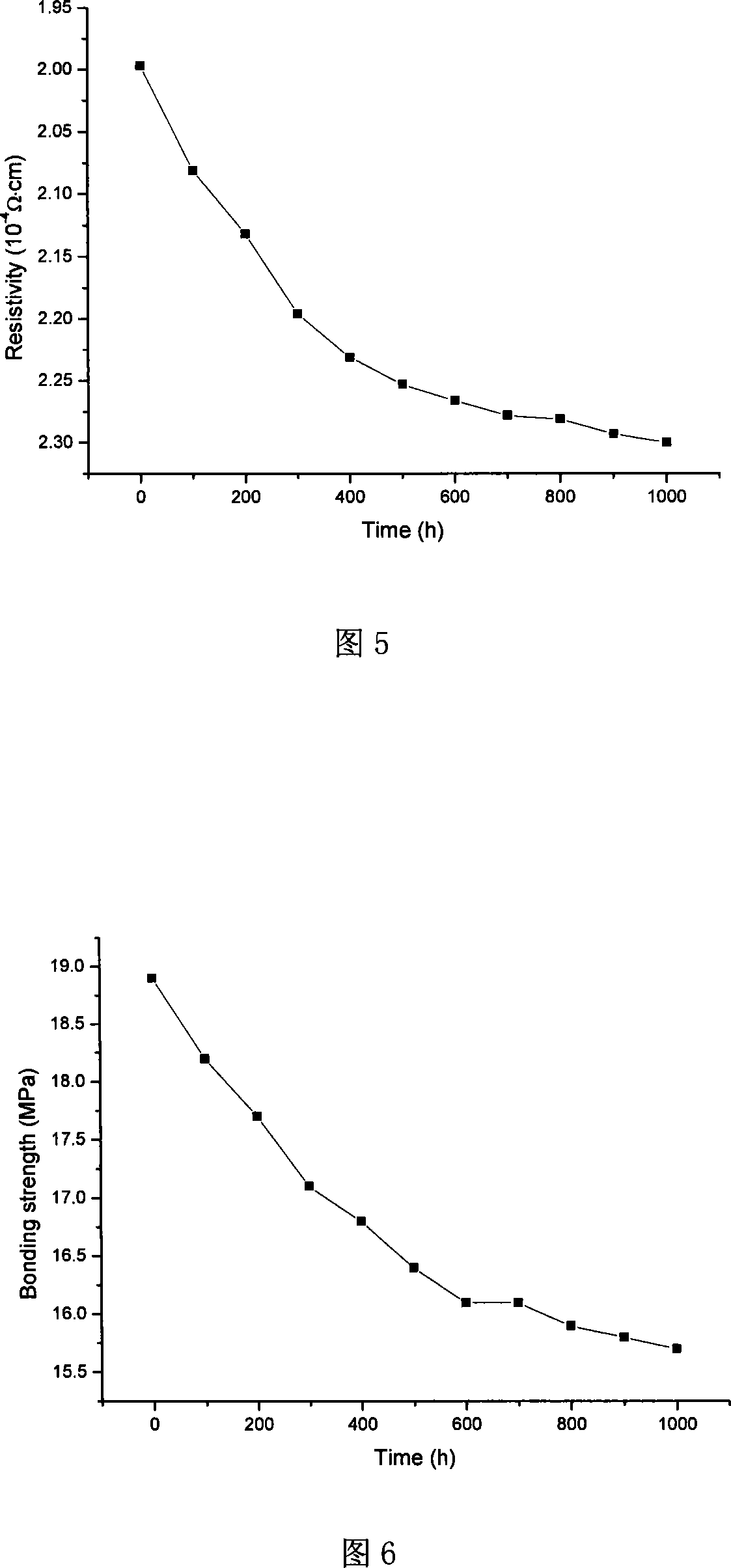

[0029] According to the formula of the weight percentage of each raw material component listed in the table below, the material was taken and the conductive adhesive sample 1, sample 2, sample 3 and sample 4 were obtained according to the above process; the weight percentage of nano silver powder was 10%.

[0030] Table 1 adds the formula (wt %) of the conductive glue of nano-silver powder 10%

[0031]

[0032] Weigh the weight of each raw material component according to the formula in Table 1 above, place the epoxy resin E-51 at a constant temperature of 120°C for 30 minutes, fully remove the water, and then add a certain amount of toughening agent dibutyl phthalate Then add a certain amount of mixed silver powder of nano-silver powder and micro-silver powder prepared in advance, and then put it into the KK-50S type swimming type stirring and defoaming device and stir for 30 minutes at a speed of 1440rpm to make it fully mixed; then Then add a certain amount of curing agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com