Staircase anti-biting bar and forming technology thereof

An anti-pinch and escalator technology, which is applied in escalators, transportation and packaging, etc., can solve the problems that the anti-pinch strips and apron boards are not straight, the clip strips are easy to arch in the middle, and daily maintenance is difficult, so as to facilitate cleaning and maintenance, The effect of smooth appearance and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

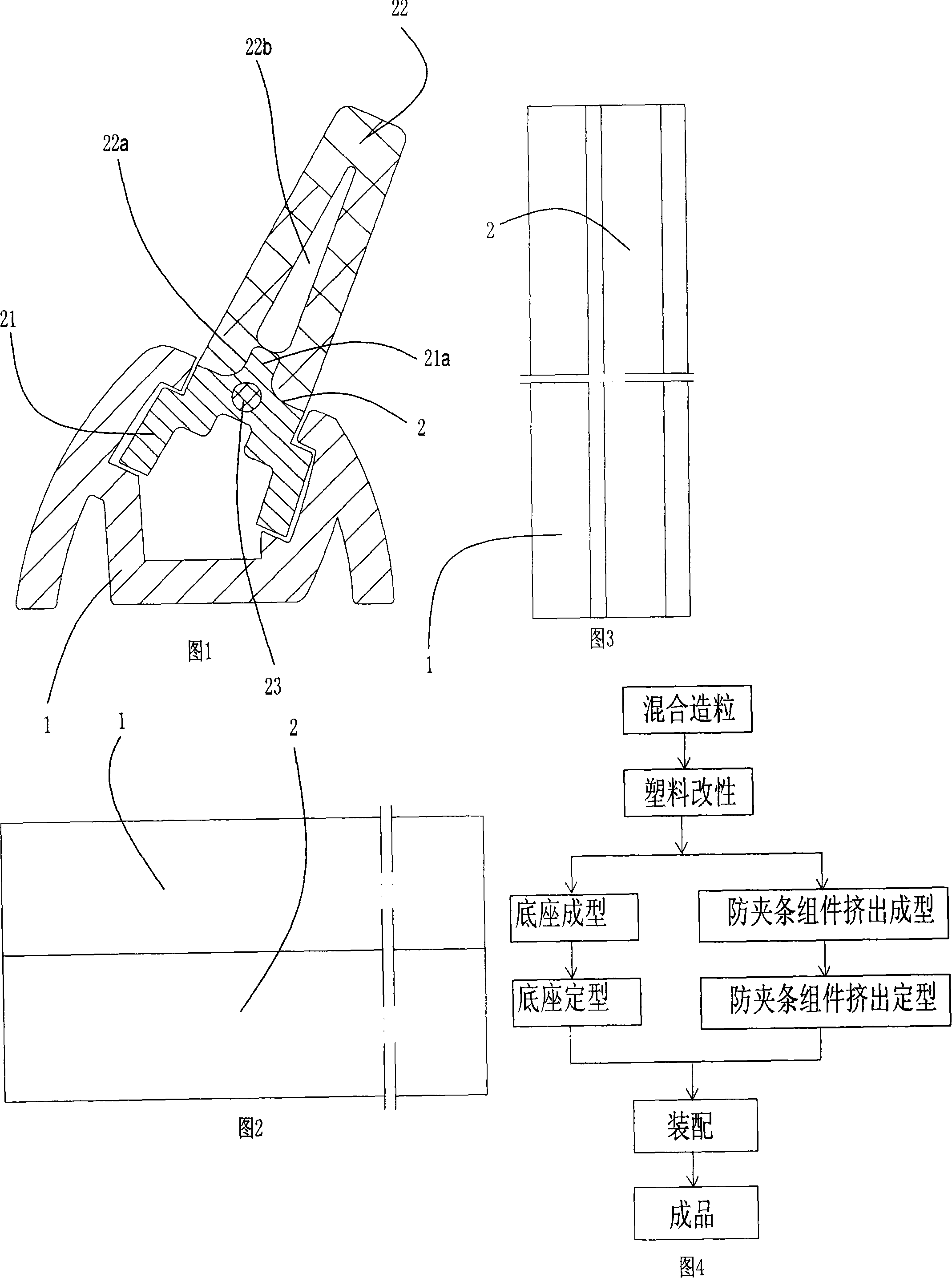

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] The embodiment shown in Fig. 1 to Fig. 4, reference number description: base 1, anti-pinch bar assembly 2, anti-pinch fixing bar 21, convex rib 21a, anti-pinch bar 22, groove 22a, cavity body 22b , Metal blank 23.

[0034] In the embodiment of the present invention, the anti-pinch bar of the escalator includes a base 1 and an anti-pinch bar assembly 2 installed on the apron of the escalator. The anti-pinch strip assembly 2 is also formed with an anti-pinch retaining strip 22 that protrudes outwards and extends on one side of the anti-pinch fixing strip 21; Metal blank 23.

[0035] This embodiment is realized in the following way: the anti-pinch fixing strip 21 is formed with a raised rib 21a along one edge, and the anti-pinch bar 22 is formed with a groove 22a that can be adhered to the convex rib 21a. A hollow body 22b is formed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com