Low-odor sterilization reinforced ABS (acrylonitrile butadiene styrene) automobile rearview mirror frame material and method for preparing same

An automotive rearview mirror and low odor technology, which is applied in the field of low odor sterilization and enhanced ABS automotive rearview mirror frame materials and preparation, can solve the problems of large influence on the mechanical properties of materials, large amount of addition and removal, etc., and achieves weather resistance and mechanical properties. Excellent performance, stable size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

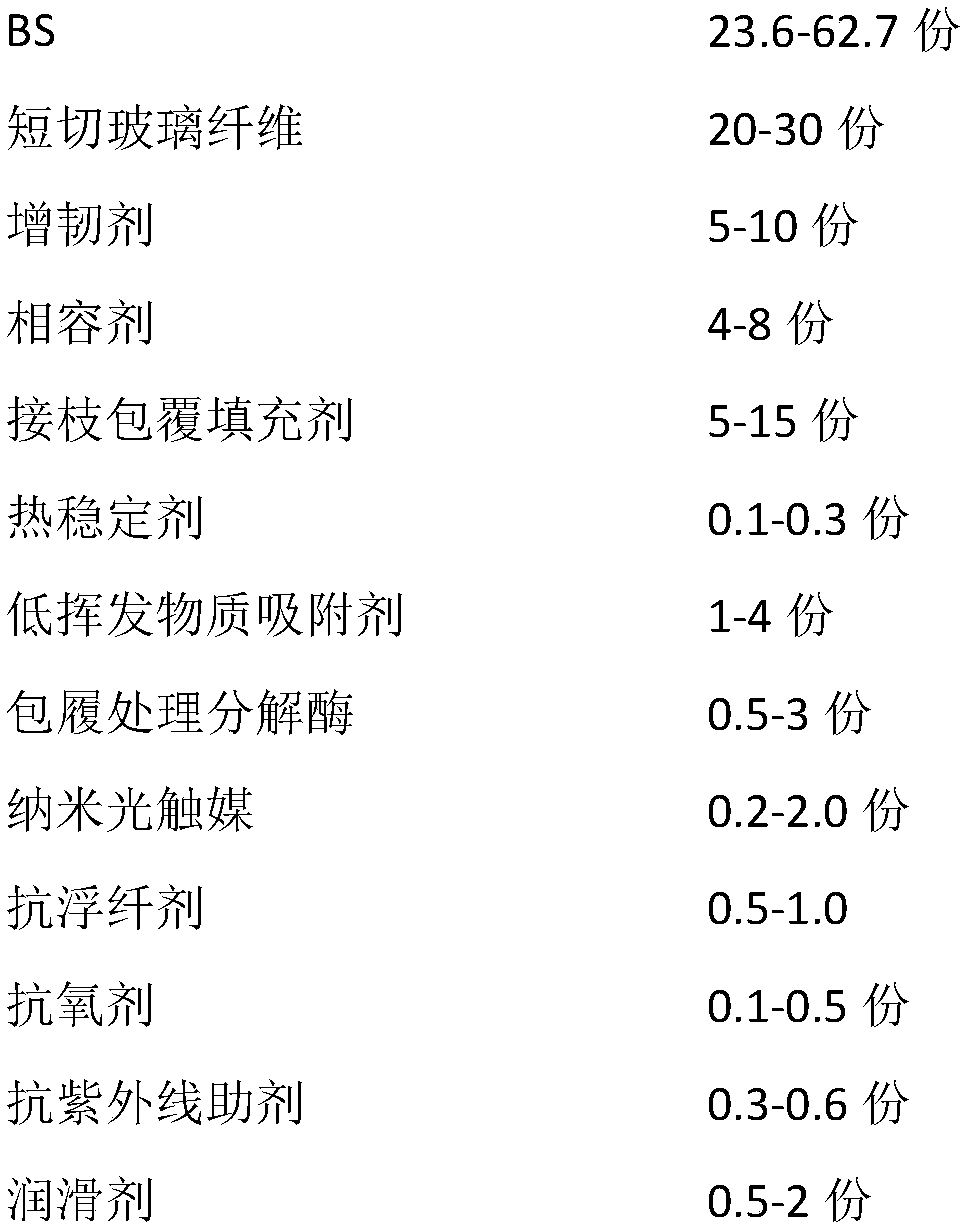

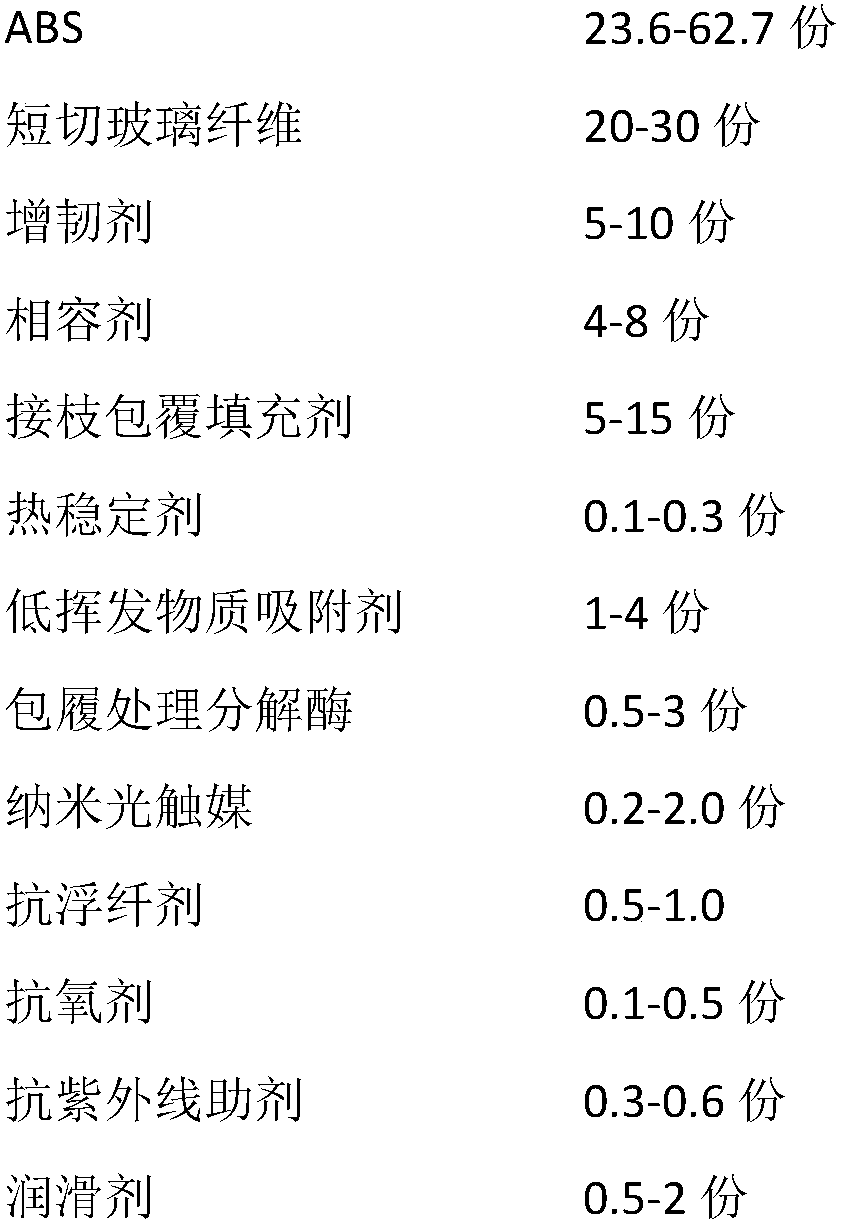

Method used

Image

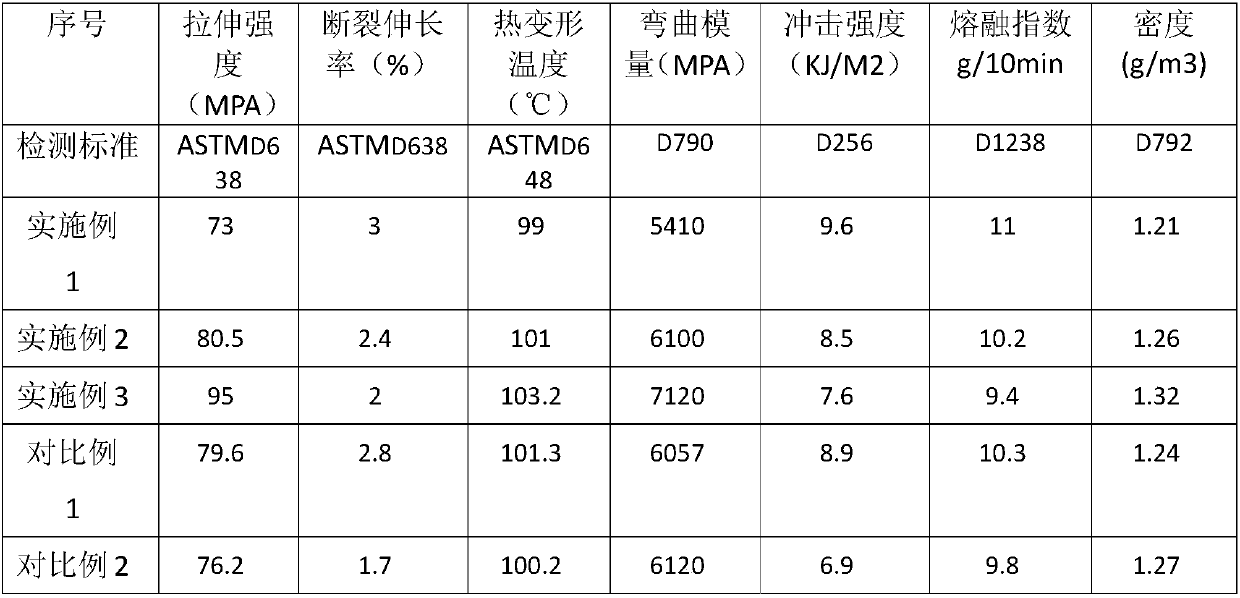

Examples

Embodiment 1

[0049] (1) The preparation method of graft coating filler:

[0050] 1) Add the calcium sulfate whiskers into the high-speed mixer, stir at high speed, and the temperature reaches 110°C, remove the moisture in the whiskers, and then add acrylonitrile, styrene and maleic anhydride copolymer (SMA800 from Shanghai Huawen) into the high-speed mixer. In the mixer, keep the temperature not lower than 100°C, blend for 26 minutes, then cool to 40°C, then take it out for use, called AS graft-coated calcium sulfate whiskers.

[0051] 2) Add the calcium sulfate whiskers into the high-speed mixer, stir at a high speed, and the temperature reaches 110°C, remove the moisture in the whiskers, and then add acrylonitrile, styrene, styrene-butadiene rubber and maleic anhydride copolymer (Shanghai Huawen's HW‐100M) into a high-speed mixer, keep the temperature not lower than 100°C, blend for 25 minutes, then cool to 40°C, then take it out for use, called AS‐co‐SBR graft-coated calcium sulfate whi...

Embodiment 2

[0060] (1) Preparation method of graft coating filler

[0061] 1) Add the calcium sulfate whiskers into the high-speed mixer, stir at a high speed until the temperature reaches 110°C, remove the moisture in the whiskers, then add acrylonitrile, styrene and maleic anhydride copolymer into the high-speed mixer, and keep the temperature constant Below 100°C, blend for 20 minutes, then cool to 40°C, then take it out for use, called AS graft-coated calcium sulfate whiskers.

[0062] 2) Add the calcium sulfate whiskers into the high-speed mixer, stir at a high speed, and the temperature reaches 110°C, remove the moisture in the whiskers, and then add acrylonitrile, styrene, styrene-butadiene rubber and maleic anhydride copolymer (Shanghai Huawen's HW‐100M) into a high-speed mixer, keep the temperature not lower than 100°C, blend for 30 minutes, then cool to 40°C, then take it out for use, called AS‐co‐SBR graft-coated calcium sulfate whiskers .

[0063] (3) When using, mix the two...

Embodiment 3

[0071] (1) Preparation method of graft coating filler

[0072] 1) Add the calcium sulfate whiskers into the high-speed mixer, stir at a high speed until the temperature reaches 110°C, remove the moisture in the whiskers, then add acrylonitrile, styrene and maleic anhydride copolymer into the high-speed mixer, and keep the temperature constant Below 100°C, blend for 30 minutes, then cool to 40°C, then take it out for use, called AS graft-coated calcium sulfate whiskers.

[0073] 2) Add the calcium sulfate whiskers into a high-speed mixer, stir at a high speed, and the temperature reaches 110°C to remove the moisture in the whiskers, and then add acrylonitrile, styrene, styrene-butadiene rubber and maleic anhydride copolymer (Shanghai Huawen's HW‐100M) into a high-speed mixer, keep the temperature not lower than 100°C, blend for 20 minutes, then cool to 40°C, then take it out for use, called AS‐co‐SBR graft-coated calcium sulfate whiskers .

[0074] 3) When using, mix the two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com