High-heeled shoes with replaceable heels

A replaceable, high-heeled shoe technology, applied in the direction of footwear, heels, heel pads, etc., can solve the problems of complicated processing technology, inelasticity, cumbersome operation, etc., and achieve high material utilization and strength performance, and disperse materials Loss and strength loss, the effect of simple replacement procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

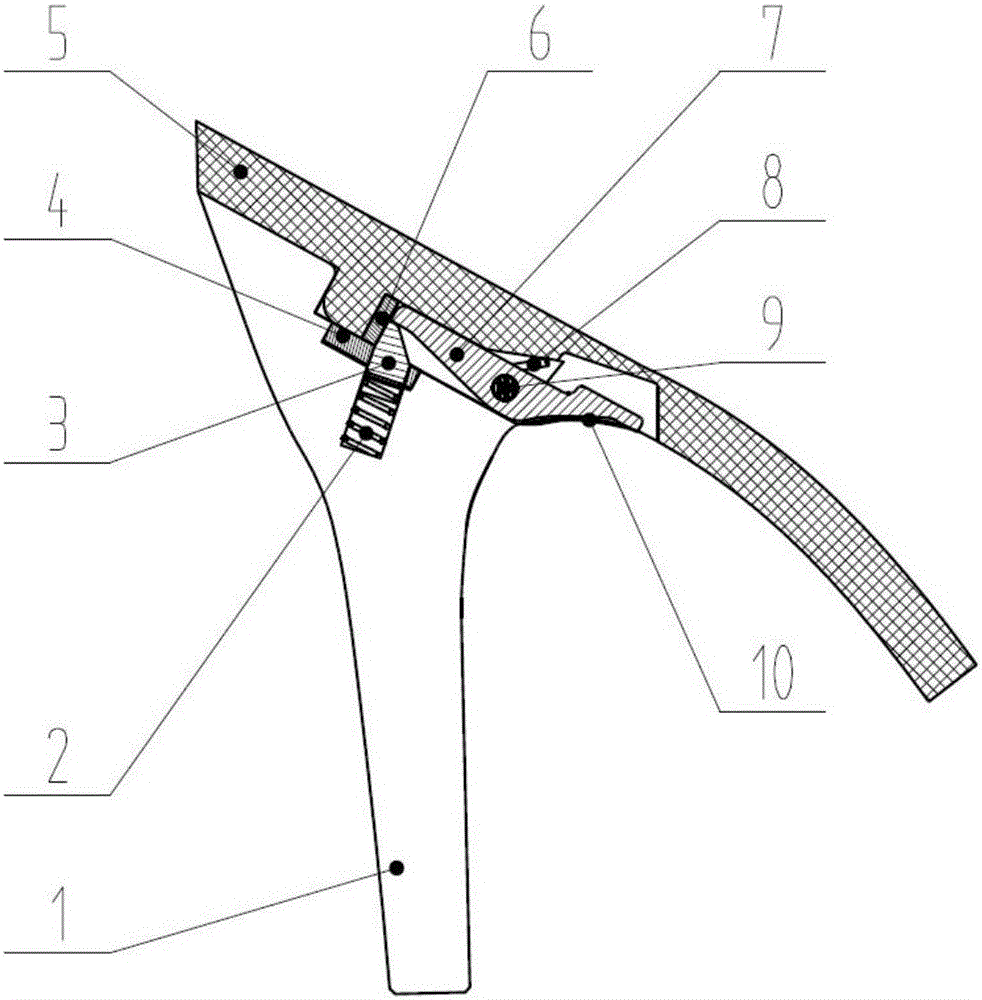

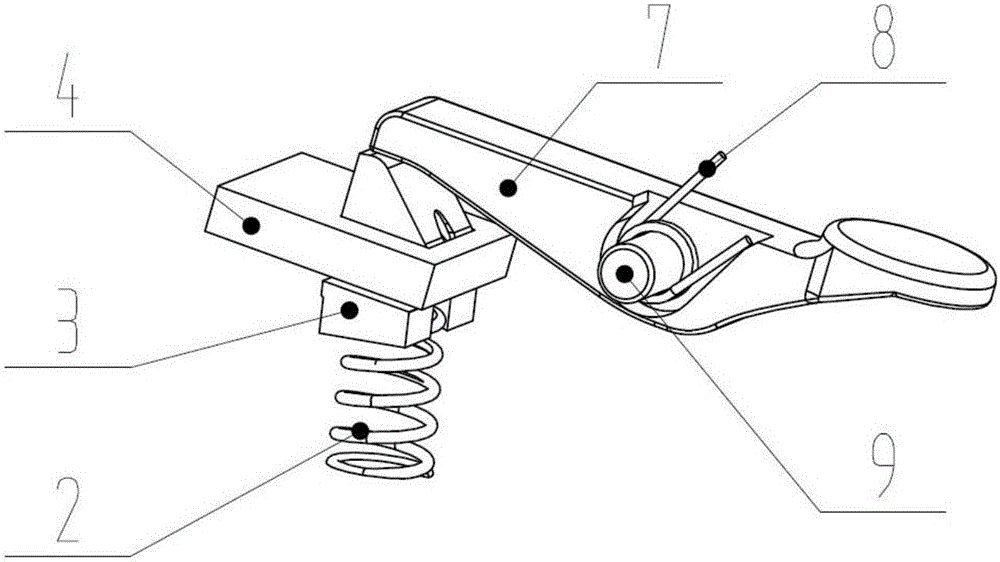

[0039] Example 1: figure 1 It is a schematic diagram of the overall structure of Embodiment 1 of the present invention, a high-heeled shoe with a replaceable heel, including a sole 5 and a heel 1, and a heel-off docking device is arranged between the sole 5 and the heel 1 of the high-heeled shoe, and the heel-off docking device includes The clamping structure is fixed on the heel 1, the elastic ejector pin that engages the shoe sole 5, and the pressure bar structure that is fixed on the sole 5 and drives the elastic ejector pin to separate from the sole 5. Groove and the block that mortises and mortises with the groove, the block is set on the sole 5, the block is formed by the first groove 501 on the sole 5, the bottom surface of the first groove 501 is parallel to the upper plane of the heel 1, elastic The push rod is located in the slot of the heel 1, figure 2 It is a schematic diagram of the structure of the pressure rod structure and the elastic ejector rod in Embodime...

Embodiment 2

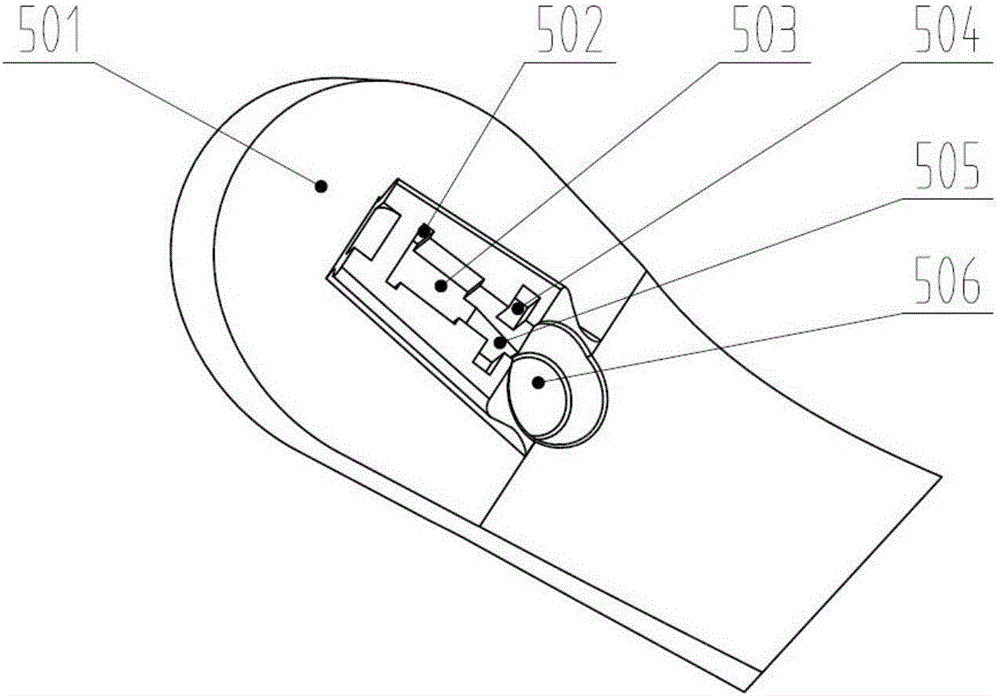

[0042] Embodiment 2: In this embodiment, the button 10 and the pressing rod 7 are integrally formed, the soft rubber pad on the button 10 is cemented with the material of the sole 5, and the soft rubber pad and the pressing rod 7 are fixed together, which is convenient for assembly. The fixed shaft 9 is two semi-axles protruding from the side of the pressure bar 7 and integrally formed with the pressure bar 7. They are fixed in the fourth groove 504 through interference fit, and the second spring 8 is not provided, because the shoe sole 5 and the shoe In the process of combining with 1, the movable push rod 3 of the elastic push rod will withstand the end face of the pressure rod 7 to make it reset, the shape of the button 10 is disc-like or polygonal, and the shape of the sixth groove 506 is circular or polygonal. The bottom surface of the groove of the fixed wear-resistant metal sheet 6 forms an included angle of 15 degrees with the upper plane of the heel 1, and the middle p...

Embodiment 3

[0043] Example 3: Figure 5 It is a schematic diagram of the sole structure of Embodiment 3 of the present invention. In this embodiment, the fixed shaft 9 is a shaft that passes through the through hole of the pressure rod 7 and forms an angle of 90 degrees with the side of the pressure rod 7, and is fixed on the sole 5 through interference fit. In the slot hole 12 or the through hole, the material of the heel 1 and the sole 5 is 304 stainless steel, and the fixed piece 4, the wear-resistant metal sheet 6 and the soft rubber pad are not provided. The function of the movable ejector rod 3 is not affected if the soft rubber pad is not provided. It is directly buckled on the flange of the second groove 502. The first spring 2 is an air spring. The reinforcing rod forms an angle of 65 degrees with the upper plane of the heel 1. The middle part of the heel 1 is provided with a reinforcing rod. The upper plane of the heel 1 forms an angle of 70 degrees, the joint surface of the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com