Dual-alloy compound cylinder body and manufacture method thereof

A composite cylinder and double alloy technology, applied in cylinders, cylinder heads, engine components, etc., to achieve high heat transfer efficiency, smooth and beautiful appearance, and improve heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

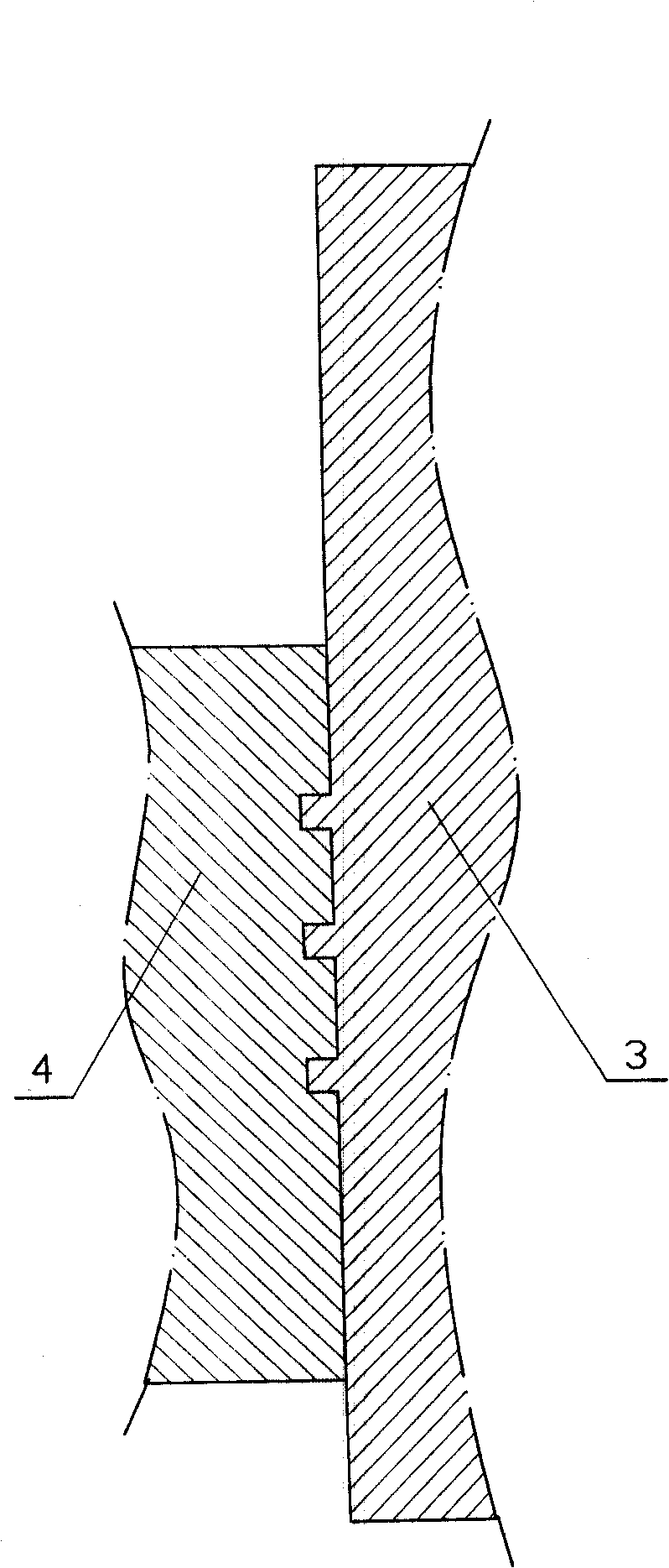

[0025] Embodiment: adopt the present invention to manufacture double-alloy composite cylinder block:

[0026] In the first step, a cylinder liner blank is prepared according to a conventional method by using a chromium-vanadium-titanium cast iron alloy containing 0.25% to 0.35% of chromium, 0.32% to 0.38% of vanadium and 0.05% to 0.1% of titanium;

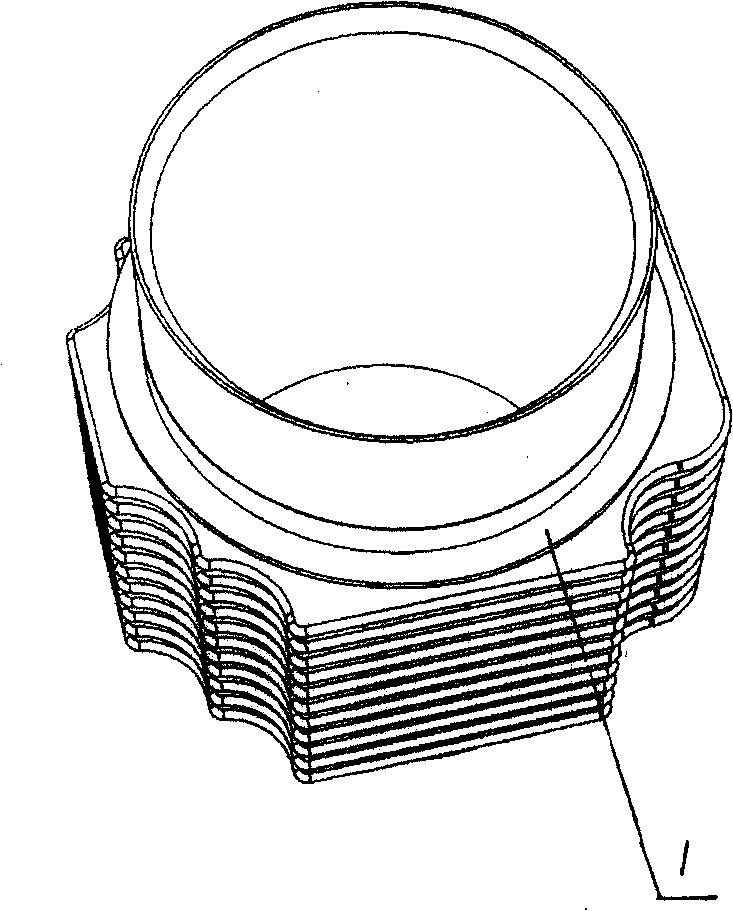

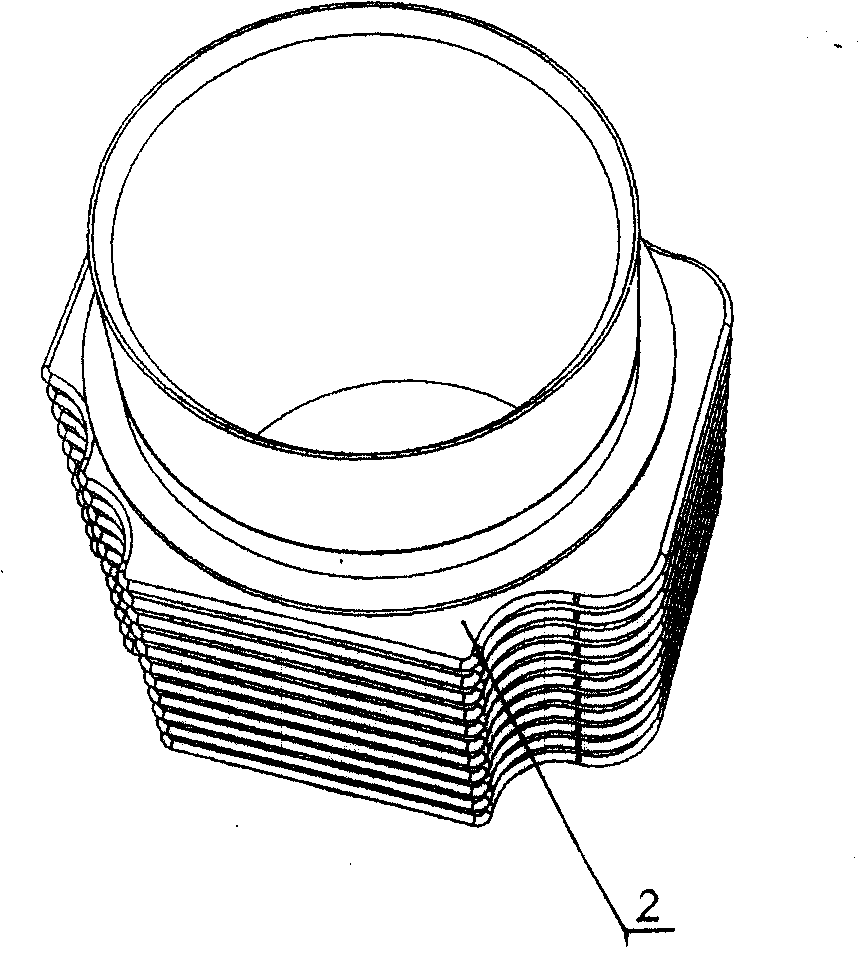

[0027] The second step is to use a precision CNC lathe to turn and process three protruding inlaid rings with a cross-sectional size of 2mm×2mm on the outer wall of the cylinder liner blank;

[0028] The third step is to preheat the cylinder liner with the inlaid ring, place it in the middle of the pre-designed mold and fix it with a steel core, and then close the left and right molds for use;

[0029] The fourth step is to use the aluminum alloy containing 6% to 8% of silicon and 0.2% to 0.4% of magnesium to melt in the No. 1 pit-type electric furnace, and when the temperature rises to about 710°C, transfer the molten aluminum to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com