Efficient water-based mold release agent for aluminum alloy die casting

A release agent and aluminum alloy technology, which is applied in the field of high-efficiency water-based release agent for aluminum alloy die-casting and aluminum alloy die-casting, can solve the problems of poor release effect and poor performance stability, and achieve good release effect and good heat resistance. , good film-forming effect

Inactive Publication Date: 2018-01-23

TIANJIN AOLUPU LUBRICATION TECH CO LTD

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Aiming at the common problems of domestic water-based release agents such as poor release effect and poor performance stability, the study was carried out from the aspects of release agent formulation and preparation process determination, release agent performance testing and actual production trials.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

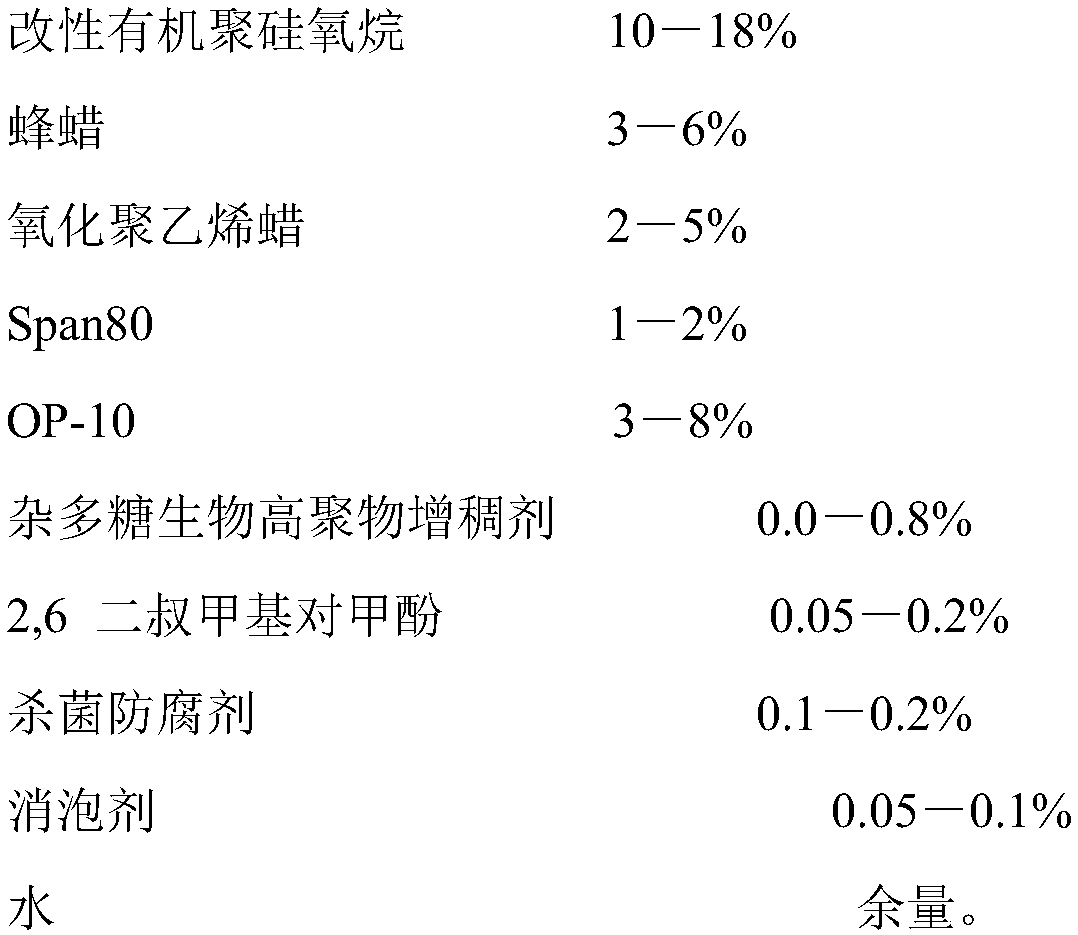

[0017] A high-efficiency water-based release agent for aluminum alloy die-casting, its components and mass percentages are:

[0018]

Embodiment 2

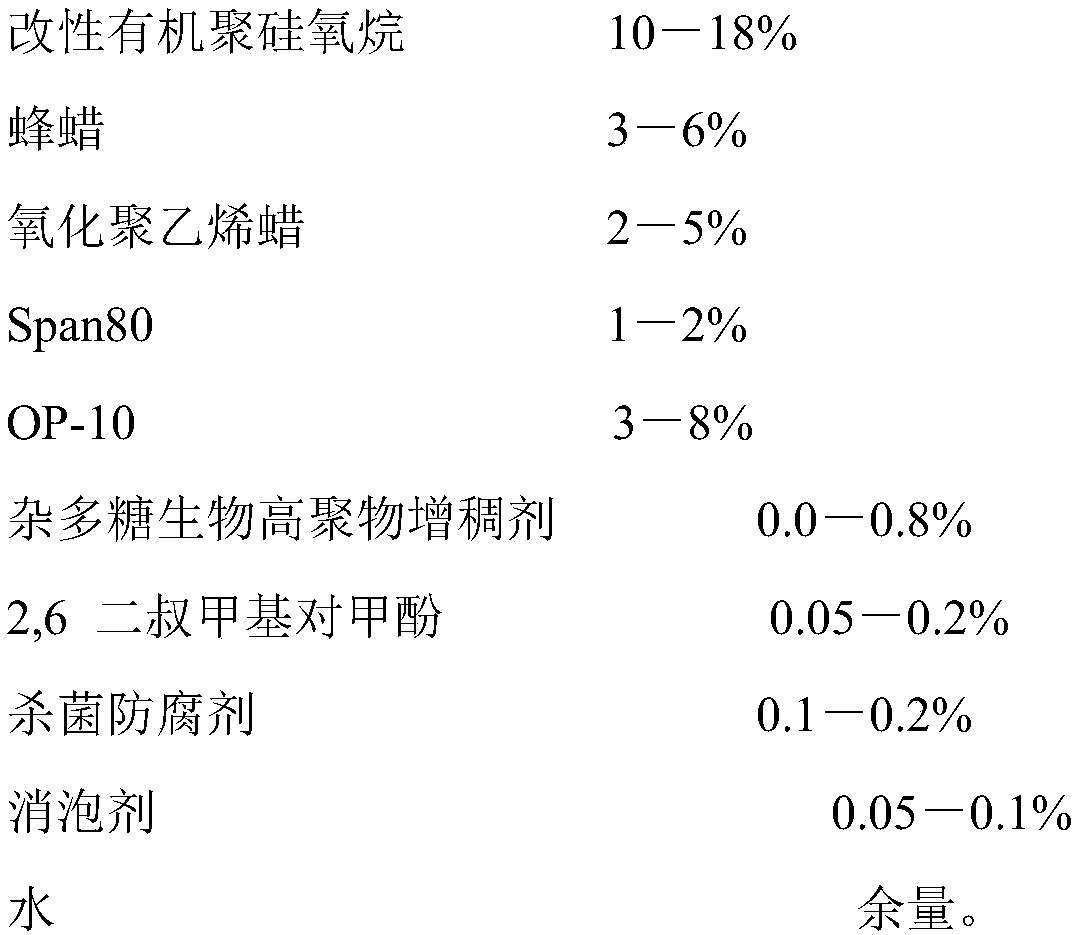

[0020] A high-efficiency water-based release agent for aluminum alloy die-casting, its components and mass percentages are:

[0021]

[0022]

Embodiment 3

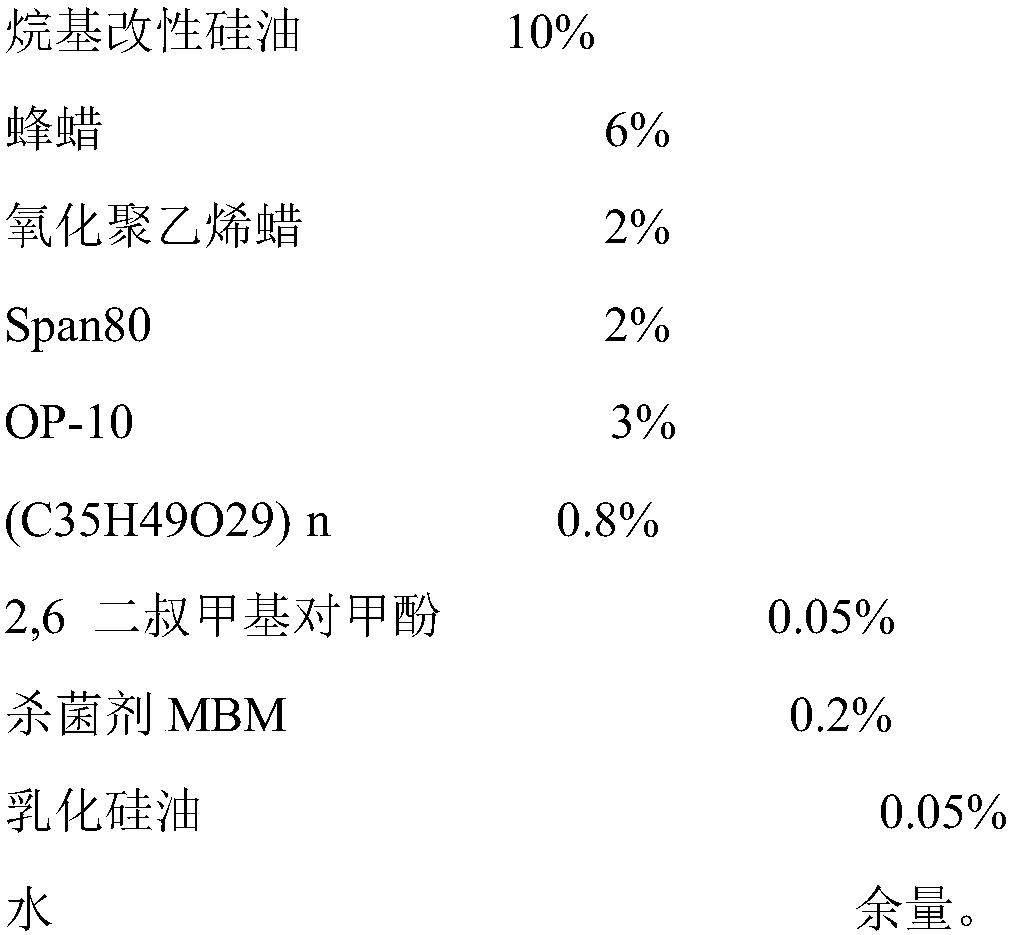

[0024] A high-efficiency water-based release agent for aluminum alloy die-casting, its components and mass percentages are:

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an efficient water-based mold release agent for aluminum alloy die casting. The efficient water-based mold release agent for aluminum alloy die casting comprises, by mass, 10%-18% of modified organic polysiloxane, 3%-6% of bee wax, 2%-5% of oxidized polyethylene wax, 1%-2% of Span80, 3%-8% of OP-10, 0-0.8% of heteropolysaccharide biopolymer thickening agent, 0.05%-0.2% of2,6-di-tert-butyl-4-methylphenol, 0.1%-0.2% of sterilizing preservative, 0.05%-0.1% of antifoaming agent and the balance water. The water-based emulsion mold release agent is high in stability, the high-temperature wetting temperature is 320 DEG C, and the film forming property is good, the efficient water-based mold release agent can easily form a uniform lubricating film having a certain strength on the surface of metal, and effective lubricating agents achieve stable and continuous gas formation at high temperature; trial application to complicated aluminum alloy die casting production shows that the mold release effect is good, and the surface of the casting is smooth and clean.

Description

technical field [0001] The invention belongs to the field of release agents and relates to aluminum alloy die-casting, in particular to a high-efficiency water-based release agent for aluminum alloy die-casting. Background technique [0002] Water-based mold release agent is widely used in aluminum alloy die-casting production due to its advantages such as good mold release, less pollution, less pores and smooth surface of the resulting casting, adjustment of mold temperature to improve mold life, and automatic operation. Aiming at the common problems of poor release effect and performance stability of domestic water-based release agents, the research was carried out from the aspects of release agent formulation and preparation process determination, release agent performance testing and actual production trials. Contents of the invention [0003] The purpose of the present invention is to overcome the shortcomings of the prior art and provide a high-efficiency water-based...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B22C3/00

Inventor 孙兰凤

Owner TIANJIN AOLUPU LUBRICATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com