Modification method and device for heavy calcium carbonate special for wires and cables

A heavy calcium carbonate, wire and cable technology, applied in chemical instruments and methods, fibrous fillers, dyeing physical treatment, etc., can solve the problems of mechanical properties decline of composite materials, poor modification effect, interface defects, etc. Short sex time, shorten modification time, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

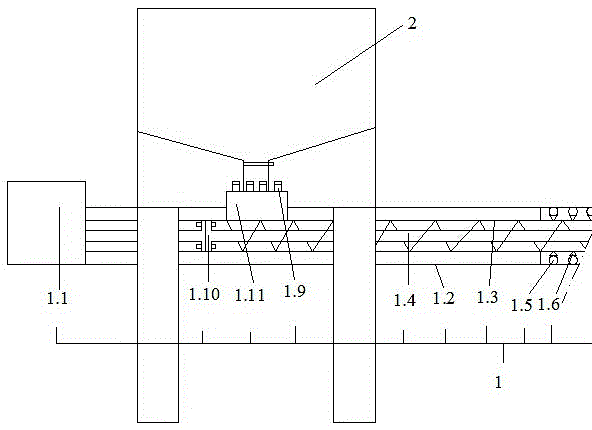

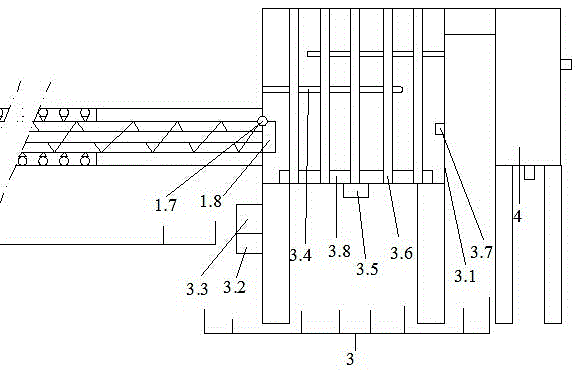

[0018] exist Figure 1A with Figure 1B Among them, the method for modifying heavy calcium carbonate dedicated to electric wire and cable is characterized in that it comprises the following steps:

[0019] 1) Add heavy calcium carbonate into the grinding device 2 and grind it into fine powder to an average particle size of 1500-2000 mesh;

[0020] 2) Add water, stearic acid, aluminate coupling agent and polyester hyperdispersant to the powder through four feeding pipes 1.12 to form a mixture. Water accounts for 0.4~0.5% of the total weight of the mixture. Fatty acid accounts for 0.9%~1.1% of the total weight of the mixture, aluminate coupling agent accounts for 1%~1.2% of the total weight of the mixture; polyester hyperdispersant accounts for 0.5~0.8% of the total weight of the mixture, put the mixture into In the microwave modification device 1, carry out microwave heating modification, the heating temperature is 80 ° C, and the heating time is 8 min;

[0021] 3) Use the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com