Polymer cement waterproof coating

A waterproof coating and polymer technology, applied in the direction of coating, etc., can solve the problems of strength reduction, coating film adhesive strength, tensile strength, water seepage resistance, low temperature flexibility, swelling and softening, etc., to improve tensile strength Strength and elongation, the effect of improving engineering stability and safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In terms of mass percentage, the following components are mixed into a liquid material:

[0029] Pure acrylic emulsion: 80%;

[0030] Sodium hexametaphosphate: 1%;

[0031] Emulsified methyl silicone oil: 0.1%;

[0032] Polyvinyl ester: 5%;

[0033] Ethylene glycol: 5%;

[0034] Sodium pentachlorophenate: 1%;

[0035] Organosiloxane: 1%;

[0036] Water: 6.9%.

[0037] In terms of mass percentage, the following components are mixed into inorganic powder:

[0038] Cement with strength grade 42.5: 50%;

[0039] S95 grade specific surface area ≥ 4000cm 2 / g of finely ground slag powder: 15%;

[0040] Calcium carbonate: 10%;

[0041] Polycarboxylate superplasticizer: 0.5%;

[0042] Instant sodium silicate: 5%;

[0043] Aluminum stearate: 5%;

[0044] Methylcellulose: 0.1%;

[0045] Triethanolamine: 0.1%;

[0046] 70-140 mesh quartz sand: 14.3%.

[0047] The liquid material and inorganic powder of the above formula are mixed uniformly at a mass ratio of 1:1 to...

Embodiment 2

[0049] In terms of mass percentage, the following components are mixed into a liquid material:

[0050] Pure acrylic emulsion: 80%;

[0051] Sodium hexametaphosphate: 0.8%;

[0052] Emulsified methyl silicone oil: 0.08%;

[0053] Polyvinyl ester: 3%;

[0054] Ethylene glycol: 3%;

[0055] Sodium pentachlorophenate: 0.8%;

[0056] Organosiloxane: 1.5%;

[0057] Water: 10.82%.

[0058] In terms of mass percentage, the following components are mixed into inorganic powder:

[0059] Cement with strength grade 42.5: 40%;

[0060] Primary fly ash: 15%;

[0061] Calcium carbonate: 10%;

[0062] Polycarboxylate superplasticizer: 0.4%;

[0063] Instant sodium silicate: 5%;

[0064] Aluminum stearate: 5%;

[0065] Methylcellulose: 0.1%;

[0066] Triethanolamine: 0.1%;

[0067] 70-140 mesh quartz sand: 24.4%;

[0068] The liquid material and inorganic powder of the above formula are mixed uniformly at a mass ratio of 1:1 to obtain the polymer cement waterproof coating.

Embodiment 3

[0070] In terms of mass percentage, the following components are mixed into a liquid material:

[0071] Pure acrylic emulsion: 80%;

[0072] Sodium hexametaphosphate: 1%;

[0073] Emulsified phenylmethyl silicone oil: 0.1%;

[0074] Phosphate: 5%;

[0075] Ethylene glycol ether: 5%;

[0076] Sodium pentachlorophenate: 1%;

[0077] Organosiloxane: 1%;

[0078] Water: 6.9%.

[0079] In terms of mass percentage, the following components are mixed into inorganic powder:

[0080] Cement with strength grade 42.5: 50%;

[0081] Primary fly ash: 15%;

[0082] Calcium carbonate: 10%;

[0083] Polycarboxylate superplasticizer: 0.5%;

[0084] Instant sodium silicate: 5%;

[0085] Aluminum stearate: 5%;

[0086] Polyvinyl alcohol: 0.1%;

[0087] Triethanolamine: 0.1%;

[0088] 70-140 mesh quartz sand: 14.3%;

[0089] The liquid material and inorganic powder of the above formula are mixed uniformly at a mass ratio of 1:1 to obtain the polymer cement waterproof coating.

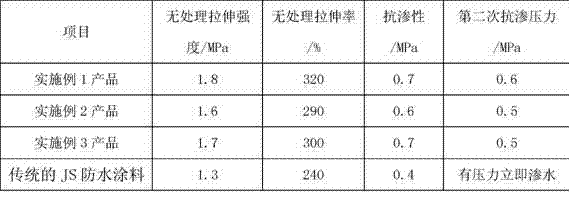

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com