Biomimetic liquid lubricating agent for drilling fluid and preparation method thereof

A drilling fluid and lubricant technology, which is applied in the field of petroleum drilling aids and liquid lubricants for drilling fluid, can solve the problems of good biodegradability, low reduction rate, high cost, etc., and achieve good biodegradability and reduce friction coefficient, the effect of reducing the adhesion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

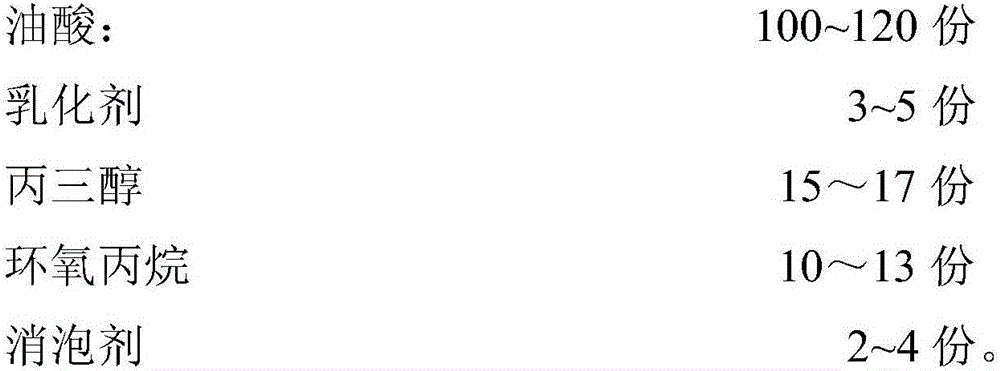

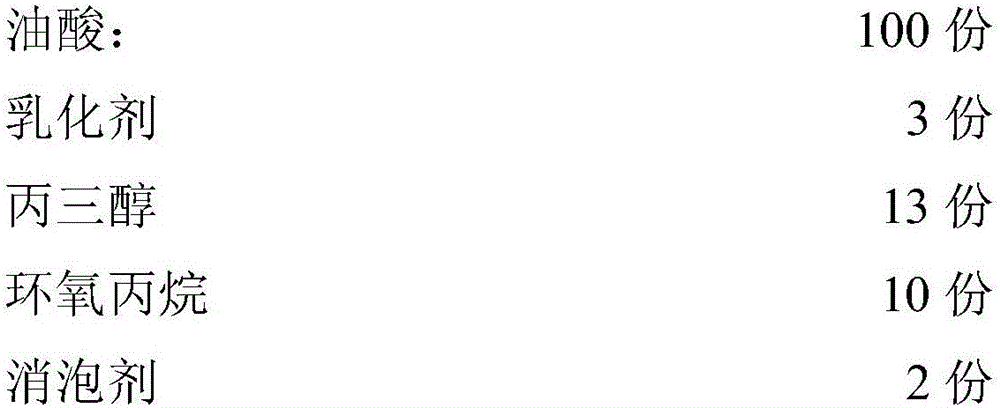

[0045] Example 1: The bionic liquid lubricant for drilling fluids of the present invention is made of raw materials with the following weight ratios:

[0046]

[0047] The above-mentioned emulsifier is a combination of triethanolamine and aluminum stearate, the weight ratio of triethanolamine and aluminum stearate is 1:2, and the defoaming agent is dimethyl silicone oil (or polydimethylsiloxane can be used Or polyoxypropylene oxide ethylene glycerol ether).

[0048] The preparation method of the biomimetic liquid lubricant for drilling fluid includes the following process steps: ① Weigh the raw materials oleic acid, emulsifier, glycerol, and propylene oxide according to the above-mentioned weight ratio, and add each raw material (in order) to the reaction In the kettle, the raw materials are fully mixed to obtain the mixture; ②The mixture is then subjected to the esterification process (esterification reaction), the esterification temperature is 200℃, the esterification time is 1h,...

Embodiment 2

[0049] Example 2: The bionic liquid lubricant for drilling fluid of the present invention is made of the following raw materials with the following weight ratio:

[0050]

[0051] The above-mentioned emulsifier is a combination of triethanolamine and aluminum stearate, the weight ratio of triethanolamine and aluminum stearate is 2:1, and the antifoaming agent is polydimethylsiloxane (or dimethyl silicone oil can be used). Or polyoxypropylene oxide ethylene glycerol ether).

[0052] The preparation method of the biomimetic liquid lubricant for drilling fluid includes the following process steps: ① Weigh the raw materials oleic acid, emulsifier, glycerol, and propylene oxide according to the above-mentioned weight ratio, and add each raw material (in order) to the reaction In the kettle, the raw materials are fully mixed to obtain the mixture; ②The mixture is then subjected to the esterification process (esterification reaction), the esterification temperature is 250℃, the esterifica...

Embodiment 3

[0053] Example 3: The bionic liquid lubricant for drilling fluids of the present invention is made of the following raw materials in weight ratio:

[0054]

[0055] The above-mentioned emulsifier is a combination of triethanolamine and aluminum stearate, the weight ratio of triethanolamine and aluminum stearate is 1:1, and the antifoaming agent is polyoxypropylene oxide ethylene glyceride (or polydimethyl dimethyl ether). Silicone or Dimethicone).

[0056] The preparation method of the biomimetic liquid lubricant for drilling fluid includes the following process steps: ① Weigh the raw materials oleic acid, emulsifier, glycerol, and propylene oxide according to the above-mentioned weight ratio, and add each raw material (in order) to the reaction In the kettle, fully mix the raw materials to obtain the mixture; ②Then the mixture is subjected to the esterification process (esterification reaction), the esterification temperature is 220 ℃, the esterification time is 1.5h, and the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com