Flame-retardant and reinforced antistatic PP composite material and preparation method thereof

A composite material and antistatic technology, which is applied in the field of flame-retardant and enhanced antistatic PP composite materials and its preparation, can solve the problems of unfavorable processing and use of plastic products, failure to meet the needs of the fire protection field, and easy to cause dust suction electric shocks, etc. Achieve the effect of increasing antistatic performance, improving dust accumulation and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

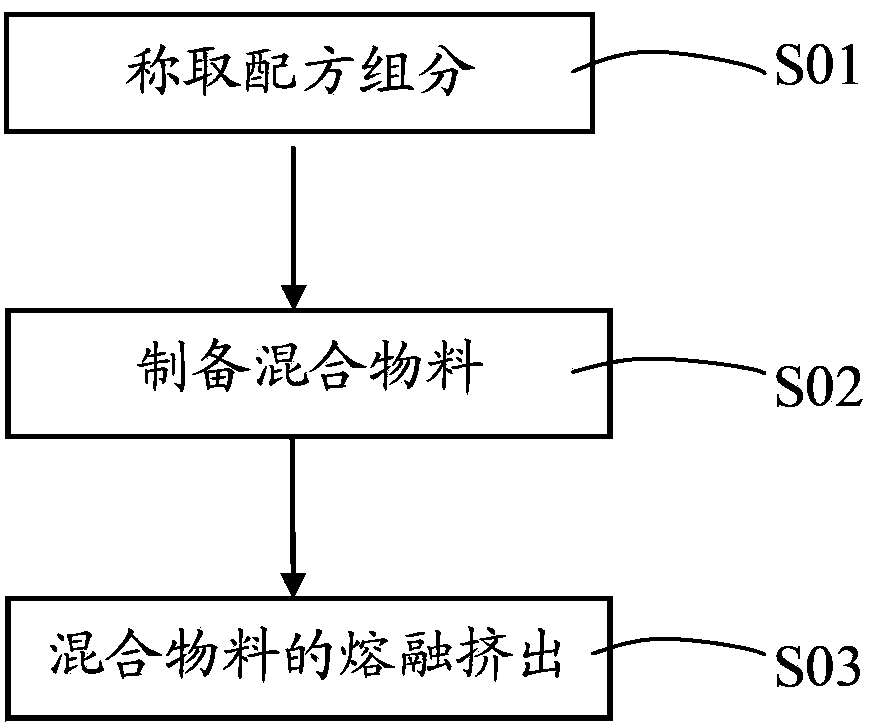

[0056] Correspondingly, an embodiment of the present invention is also a preparation method of a flame-retardant reinforced antistatic PP composite material, which includes the following steps, as attached figure 1 Shown:

[0057] S01. Weigh the formula components: Weigh each component according to the above flame-retardant enhanced antistatic PP composite material formula;

[0058] S02. Prepare a mixed material: perform mixing treatment on the weighed components except the glass fiber to obtain a mixed material;

[0059] S03. Melt extrusion of the mixed material: feed the mixed material from the main material port, and feed the glass fiber from the fiber adding port for melt extrusion and granulation to obtain the flame-retardant and enhanced antistatic PP composite material.

[0060] Specifically, the formulation of the flame-retardant enhanced antistatic PP composite material in the above step S01 and the preferred content and type of each component in the formulation are ...

Embodiment 1

[0068] A flame-retardant reinforced antistatic PP composite material preparation, including the following formula components by weight percentage:

[0069] Polypropylene 38.5%;

[0070] Homemade Compatibilizer 15%

[0071] White mineral oil 1%;

[0072] Coupling agent 0.5%;

[0073] Glass fiber 10%;

[0074] Flame retardant 16%;

[0075] Synergistic flame retardant 8%;

[0076] Antistatic agent 10%;

[0077] Compound Lubricant 1%

[0078] The preparation method of the antistatic PP composite material enhanced by the flame retardancy is as follows:

[0079] S11: Weigh each component according to the above flame-retardant reinforced antistatic PP composite material formula;

[0080] S12: Mix and mix the polypropylene, self-made compatibilizer, white mineral oil, and coupling agent in the mixer in step S11, and then mix the flame retardant, synergistic flame retardant, antistatic agent, and compound lubricant and other additives are added to the mixer and mixed evenly to...

Embodiment 2

[0083] A flame-retardant reinforced antistatic PP composite material preparation, including the following formula components by weight percentage:

[0084] Polypropylene 19.5%;

[0085] Self-made compatibilizer 22%;

[0086] White mineral oil 1%;

[0087] Coupling agent 0.5%;

[0088] Glass fiber 20%;

[0089] Flame retardant 18%;

[0090] Synergistic flame retardant 6%;

[0091] Antistatic agent 12%;

[0092] Compound Lubricant 1%

[0093] The preparation method of the antistatic PP composite material enhanced by the flame retardancy is as follows:

[0094] S21: Weigh each component according to the above flame-retardant reinforced antistatic PP composite material formula;

[0095]S22: Mix and mix the polypropylene, self-made compatibilizer, white mineral oil, and coupling agent in the mixer in step S11, and then mix the flame retardant, synergistic flame retardant, antistatic agent, and compound lubricant and other additives are added to the mixer and mixed evenly t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com