Novel high-strength uniform-strength cellulose microsphere preparation method

A cellulose microsphere, high-strength technology, applied in the field of materials, can solve problems such as poor mechanical properties of cellulose spherical materials, unsatisfactory mechanical properties, and inability to completely solve problems, and achieve easy production, low cost, Uniform intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

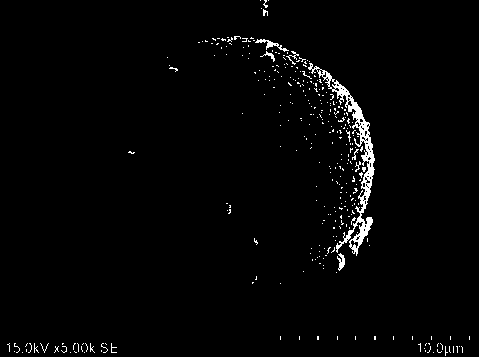

Image

Examples

Embodiment 1

[0026] Dissolve 5g of microcrystalline cellulose in 95ml of sodium hydroxide / urea solution at -5°C, then place the cellulose solution in an ice bath, add the crosslinking agent epichlorohydrin drop by drop, and mechanically stir at the same time at a speed of 10,000 rpm, stirring time 60min; after centrifuging and degassing the solution obtained in the previous step, use a syringe to draw 1ml of this solution as a dispersed phase, fix it in a syringe pump, use a syringe to draw 5ml of white mineral oil and add 0.25g of Span80 as a continuous phase, fix In another syringe pump, using a T-type microfluidic device, place the liquid outlet in 50ml of 5% Span80 white mineral oil solution, and prepare emulsions containing cellulose droplets of different particle sizes by adjusting the two-phase flow rate ; The emulsion was placed in an environment of 20 ° C for 8 hours, while magnetically stirring at 2000 rpm; and then 5% acidic solution was added to obtain regenerated cellulose micr...

Embodiment 2

[0028] Dissolve 6g of bamboo cellulose in 94ml of sodium hydroxide / urea solution at -5°C, then place the cellulose solution in an ice bath, add the crosslinking agent epichlorohydrin drop by drop, and mechanically stir at the same time at a speed of 10,000 rpm , stirring time 30min; after centrifuging and degassing the solution obtained in the previous step, use a syringe to draw 1ml of this solution as a dispersed phase, fix it in a syringe pump, use a syringe to draw 5ml of white mineral oil and add 0.25g of Span80 as a continuous phase, and fix it in Another syringe pump, using a T-type microfluidic device, placed the liquid outlet in 50ml of 5% Span80 white mineral oil solution, and prepared emulsions containing cellulose droplets of different particle sizes by adjusting the two-phase flow rate; The emulsion was placed in an environment of 20°C for 8 hours, and magnetically stirred at 2000 rpm at the same time; then the emulsion obtained in the previous step was heated to 7...

Embodiment 3

[0030] Dissolve 8g of microcrystalline cellulose in -5°C sodium hydroxide / urea 92ml solution, then place the cellulose solution in an ice bath, add the cross-linking agent ethylene glycol glycidyl ether drop by drop, and mechanically stir at the same time, the speed 10000 rpm, stirring time 45min; after centrifuging and degassing the solution obtained in the previous step, use 10ml of this solution as a dispersed phase, fix it on a syringe pump, use 90ml of white mineral oil and add surfactant 5gSpan80 as a continuous phase, and mechanically stir ( 2000 rpm) to emulsify this solution for 8 hours; then add the emulsion obtained in the previous step to 5% acidic solution to obtain regenerated cellulose microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com