Modified elastomer of nylon 6 and preparation method thereof

An elastomer and nylon technology, applied in the field of nylon 6 modified elastomer and its preparation, can solve problems such as poor compatibility and affect product performance, and achieve the effects of excellent toughness, improved product hardness and good tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

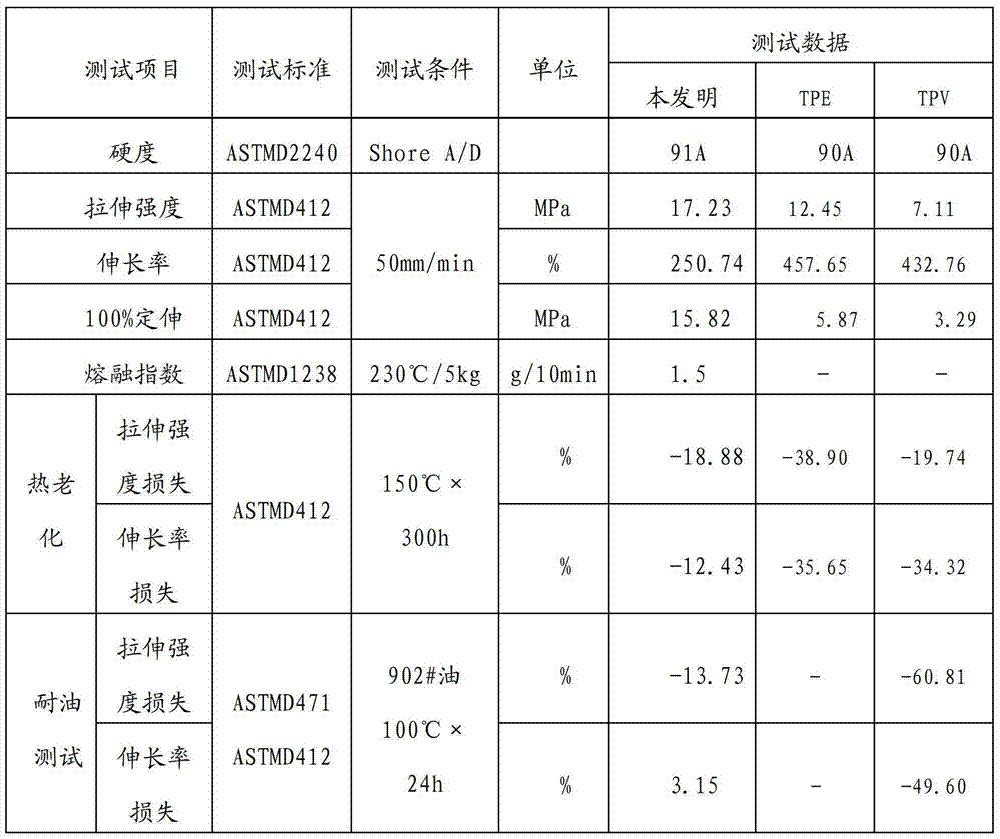

Image

Examples

Embodiment 1

[0020] A modified elastomer of nylon 6, comprising the following components by weight: 15 parts of PA6, 5 parts of maleic anhydride grafted EPDM, 10 parts of SEBS, 15 parts of ultra-low density polyethylene, 1 part of calcium stearate, white ore 1 part of oil, wherein the grafting rate of maleic anhydride grafted EPDM is 0.8%.

[0021] A kind of preparation method of the modified elastomer of above-mentioned nylon 6, comprises the following steps:

[0022] First add PA6 and 1 part of white mineral oil into the blender, stir evenly, then add calcium stearate to it, stir evenly, continue to add maleic anhydride grafted EPDM, ultra-low density polyethylene and SEBS to it, After it is evenly stirred, it is introduced into a twin-screw extruder. The processing technology is as follows: the temperature of the first zone is 190-220°C, the temperature of the second zone is 190-220°C, the temperature of the third zone is 195-225°C, the temperature of the fourth zone is 195-225°C, and t...

Embodiment 2

[0024] A modified elastomer of nylon 6, comprising the following components by weight: 45 parts of PA6, 10 parts of maleic anhydride grafted EPDM, 40 parts of SEBS, 45 parts of ultra-low density polyethylene, 8 parts of calcium stearate, white ore 1 part of oil, wherein the grafting rate of maleic anhydride grafted EPDM is 1%.

[0025] A kind of preparation method of the modified elastomer of above-mentioned nylon 6, comprises the following steps:

[0026] First add PA6 and 1 part of white mineral oil into the blender, stir evenly, then add calcium stearate to it, stir evenly, continue to add maleic anhydride grafted EPDM, ultra-low density polyethylene and SEBS to it, After it is evenly stirred, it is introduced into a twin-screw extruder. The processing technology is as follows: the temperature of the first zone is 190-220°C, the temperature of the second zone is 190-220°C, the temperature of the third zone is 195-225°C, the temperature of the fourth zone is 195-225°C, and t...

Embodiment 3

[0028]A modified elastomer of nylon 6, comprising the following components by weight: 670 parts of PA, 15 parts of maleic anhydride grafted EPDM, 70 parts of SEBS, 75 parts of ultra-low density polyethylene, 15 parts of calcium stearate, white ore 1 part of oil, wherein the grafting rate of maleic anhydride grafted EPDM is 1.5%.

[0029] A kind of preparation method of the modified elastomer of above-mentioned nylon 6, comprises the following steps:

[0030] First add PA6 and 1 part of white mineral oil into the blender, stir evenly, then add calcium stearate to it, stir evenly, continue to add maleic anhydride grafted EPDM, ultra-low density polyethylene and SEBS to it, After it is evenly stirred, it is introduced into a twin-screw extruder. The processing technology is as follows: the temperature of the first zone is 190-220°C, the temperature of the second zone is 190-220°C, the temperature of the third zone is 195-225°C, the temperature of the fourth zone is 195-225°C, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com