Environment-friendly anti-aging automobile inner decorating glue and preparation method thereof

An automotive interior and anti-aging technology, applied in adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as weak initial adhesion, threats to human health, and poor anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

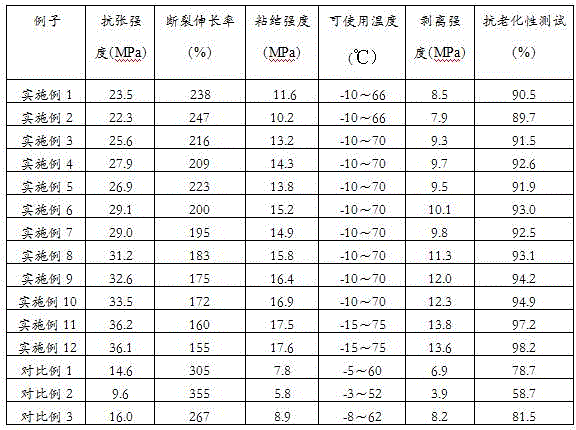

Examples

Embodiment approach

[0061] As a preferred embodiment of the present invention, in the HO-SBS, the grafting ratio of hydroxyl groups is 25-40%.

[0062] As a preferred embodiment of the present invention, in the HO-SBS, the grafting rate of hydroxyl groups is 33%.

[0063] The white mineral oil used in this application is not particularly limited, and may be a commercially available product.

[0064] The term "antioxidant" in the present invention refers to a compound that can prevent or inhibit the oxidation process by causing macromolecular chain breakage, crosslinking, and performance deterioration due to the oxidation of polymers. Antioxidants are divided into two categories: free radical terminators and hydroperoxide decomposing agents. The free radical terminator mainly generates inactive free radicals or stable products through chain transfer to terminate the chain. Sterically hindered phenols, aromatic amines and certain cyclic hydrocarbons are good free radical stabilizers. Phenolic com...

Embodiment 11)

[0133] Example 11) First put 50 parts by weight of D1, 20 parts by weight of E1 and 0.5 parts by weight of F1 into stainless steel

[0134] In the reactor, after heating up to 120°C, add 100 parts by weight of A1 and 10 parts by weight of B1, and control the temperature of the reactor within 140°C;

[0135] 2) Add 150 parts by weight of C1 and 5 parts by weight of G1 after all the SBS and HO-SBS are dissolved,

[0136] Control the temperature of the stainless steel reactor at 140°C and stir for 30 minutes;

[0137] 3) Vacuumize the inside of the reactor to -0.085Mpa, discharge the material, and pack it after cooling.

Embodiment 21)

[0138] Example 21) First put 100 parts by weight of D1, 50 parts by weight of E1 and 2 parts by weight of F1 into stainless steel

[0139] In the reactor, after heating up to 120°C, add 100 parts by weight of A1 and 10 parts by weight of B1, and control the temperature of the reactor within 140°C;

[0140] 2) Add 200 parts by weight of C1 and 20 parts by weight of G1 after all the SBS and HO-SBS are dissolved,

[0141] Control the temperature of the stainless steel reactor at 140°C and stir for 30 minutes;

[0142] 3) Vacuumize the inside of the reactor to -0.085Mpa, discharge the material, and pack it after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com