PC (Polycarbonate) film material and preparation method thereof

A thin film material, 80% PC technology, applied in the field of PC thin film material and its preparation, can solve the problems of poor solvent resistance, poor stress crack resistance, low flame retardant grade, etc., and achieve good film forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

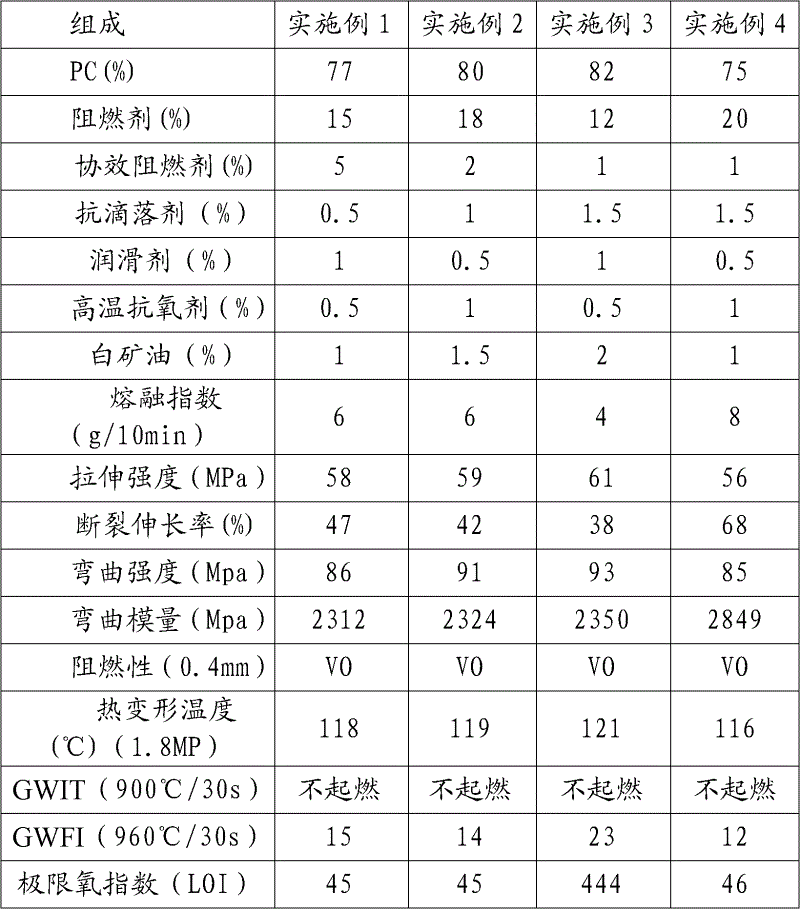

Embodiment 1

[0021] Pour the dried 77% PC raw material, 15% flame retardant, 5% flame retardant synergist, 0.5% anti-dripping agent, 0.5% high-temperature antioxidant, and 1% lubricant into a high-speed mixer, and drop 1 % white mineral oil, stir at a low speed (800rpm) for 1-3 minutes, then stir at a high speed (2000rpm) for 3-5 minutes, and set aside. Put the stirred mixture in a twin-screw machine to melt, extrude and granulate. The process conditions are as follows: twin-screw first-stage temperature 200-210°C, second-stage temperature 210-220°C, third-stage temperature 220-240°C, die head temperature 240°C.

Embodiment 2

[0023] Pour the dried 80% PC, 18% flame retardant, 2% flame retardant synergist, 1% anti-dripping agent, 1% high-temperature antioxidant, and 0.5% lubricant into a high-speed mixer, and drop 1.5 % white mineral oil, stir at a low speed (800rpm) for 1-3 minutes, and then stir at a high speed (2000rpm) for 3-5 minutes; each component is a percentage by weight and is ready for use. Put the stirred mixture in a twin-screw machine to melt, extrude and granulate. The process conditions are as follows: twin-screw first-stage temperature 200-210°C, second-stage temperature 210-220°C, third-stage temperature 220-240°C, die head temperature 240°C.

Embodiment 3

[0025] Pour the dried 82% PC, 12% flame retardant, 1% flame retardant synergist, 1.5% anti-dripping agent, 0.5% high-temperature antioxidant, and 1% lubricant into a high-speed mixer, and drop 2 % white mineral oil, stir at a low speed (800rpm) for 1-3 minutes, and then stir at a high speed (2000rpm) for 3-5 minutes; each component is a percentage by weight and is ready for use. Put the stirred mixture in a twin-screw machine to melt, extrude and granulate. The process conditions are as follows: twin-screw first-stage temperature 200-210°C, second-stage temperature 210-220°C, third-stage temperature 220-240°C, die head temperature 240°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com