Nylon-66 modified elastomer and preparation method thereof

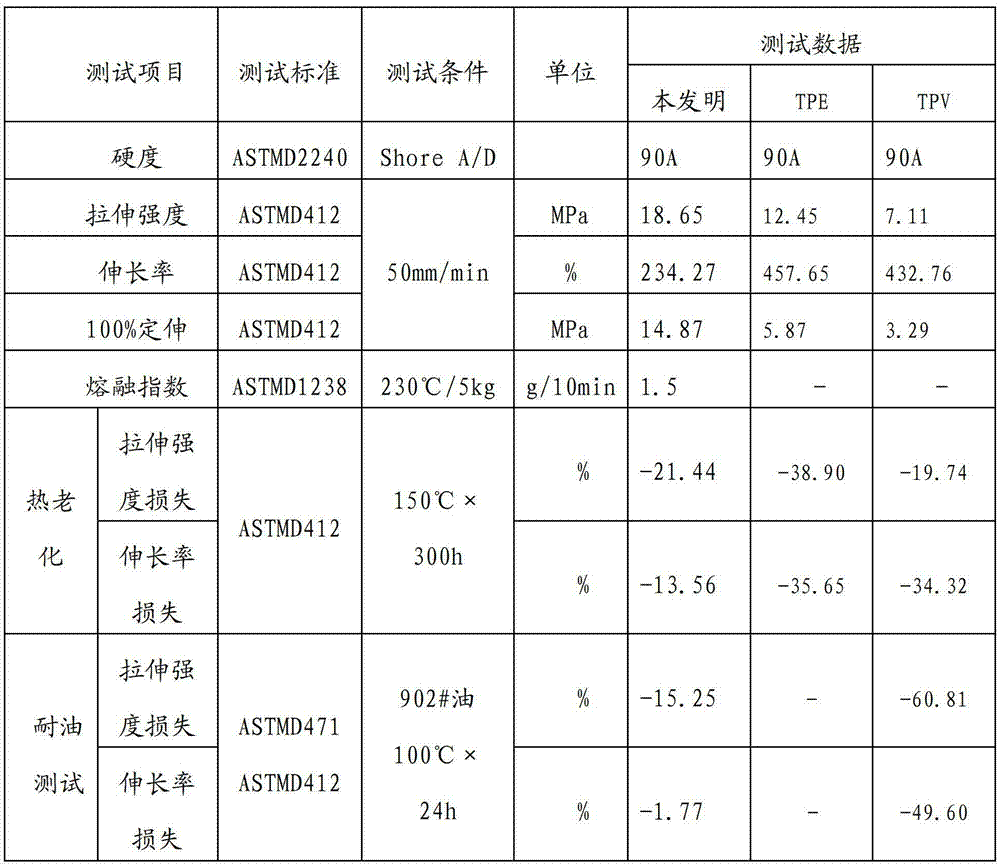

A technology of elastomer and nylon, which is applied in the field of nylon 66 modified elastomer and its preparation, can solve the problems affecting product performance and poor compatibility, and achieve the effect of improving easy peeling, excellent toughness and good tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A modified elastomer of nylon 66, comprising the following components by weight: 15 parts of PA66, 5 parts of maleic anhydride grafted EPDM, 10 parts of SEBS, 15 parts of ultra-low density polyethylene, 1 part of calcium stearate, white ore 1 part of oil, wherein the grafting rate of maleic anhydride grafted EPDM is 0.8%.

[0021] A kind of preparation method of the modified elastomer of above-mentioned nylon 66, comprises the following steps:

[0022] First add PA66 and 1 part of white mineral oil into the blender, stir evenly, then add calcium stearate to it, stir evenly, continue to add maleic anhydride grafted EPDM, ultra-low density polyethylene and SEBS to it, After it is evenly stirred, it is introduced into a twin-screw extruder. The processing technology is as follows: the temperature of the first zone is 190-220°C, the temperature of the second zone is 200-230°C, the temperature of the third zone is 205-235°C, the temperature of the fourth zone is 215-245°C, a...

Embodiment 2

[0024] A modified elastomer of nylon 66, comprising the following components by weight: 45 parts of PA66, 10 parts of maleic anhydride grafted EPDM, 40 parts of SEBS, 45 parts of ultra-low density polyethylene, 8 parts of calcium stearate, white ore 1 part of oil, wherein the grafting rate of maleic anhydride grafted EPDM is 1%.

[0025] A kind of preparation method of the modified elastomer of above-mentioned nylon 66, comprises the following steps:

[0026] First add PA66 and 1 part of white mineral oil into the blender, stir evenly, then add calcium stearate to it, stir evenly, continue to add maleic anhydride grafted EPDM, ultra-low density polyethylene and SEBS to it, After it is evenly stirred, it is introduced into a twin-screw extruder. The processing technology is as follows: the temperature of the first zone is 190-220°C, the temperature of the second zone is 200-230°C, the temperature of the third zone is 205-235°C, the temperature of the fourth zone is 215-245°C, a...

Embodiment 3

[0028] A modified elastomer of nylon 66, comprising the following components by weight: 70 parts of PA66, 15 parts of maleic anhydride grafted EPDM, 70 parts of SEBS, 75 parts of ultra-low density polyethylene, 15 parts of calcium stearate, white ore 1 part of oil, wherein the grafting rate of maleic anhydride grafted EPDM is 1.5%.

[0029]A kind of preparation method of the modified elastomer of above-mentioned nylon 66, comprises the following steps:

[0030] First add PA66 and 1 part of white mineral oil into the blender, stir evenly, then add calcium stearate to it, stir evenly, continue to add maleic anhydride grafted EPDM, ultra-low density polyethylene and SEBS to it, After it is evenly stirred, it is introduced into a twin-screw extruder. The processing technology is as follows: the temperature of the first zone is 190-220°C, the temperature of the second zone is 200-230°C, the temperature of the third zone is 205-235°C, the temperature of the fourth zone is 215-245°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com