Thermoplastic polyurethane elastomer (TPE) door seal for refrigerator and freezer and preparation method thereof

An elastic and body door technology, applied in the field of thermoplastic elastomers, door seals and their preparation, can solve problems such as shortening service life, aging, and increasing energy consumption of products, and achieves the advantages of prolonging service life, improving weather resistance and improving low temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Prepare TPE elastomer door seals as follows:

[0043] First, prepare TPE elastomer particles:

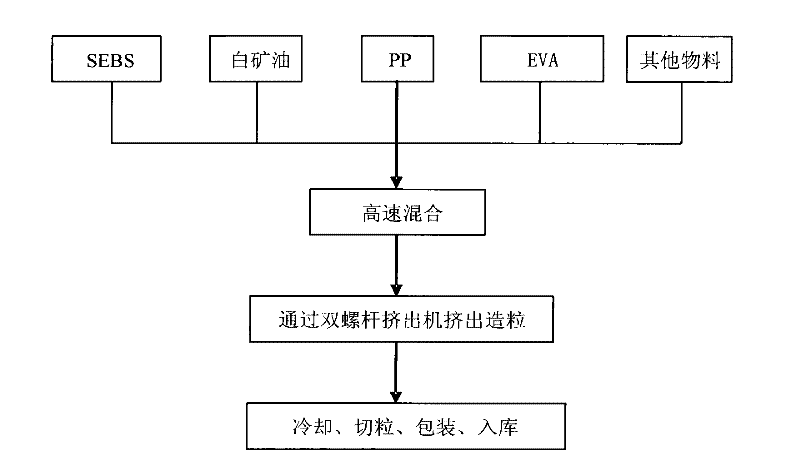

[0044] see figure 1 As shown, according to the mass weighing of each component in Example 1 in Table 1, put various raw materials into a high-speed mixer and mix them evenly, then unload the materials and store them for 2 hours, and then put them into a double mixer with L / D≥48. In the screw extruder, it is extruded and granulated to make TPE elastomer granules. After cooling, it is cut into granules and packaged for storage.

[0045] Then, prepare the TPE elastomer door seal:

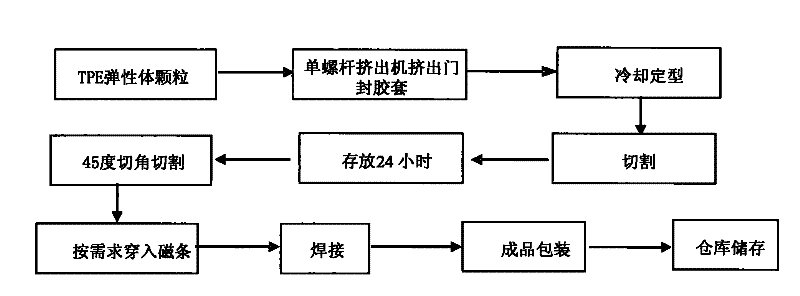

[0046] see figure 2 As shown, first, the TPE elastomer particles prepared above are extruded through a single-screw extruder to extrude the door seal rubber sleeve. After cooling and shaping, they are cut according to the length requirements and stored for 24 hours to make a TPE elastomer door. Sealing sleeve, spare.

[0047]Then, the TPE elastomer door seal rubber sleeve prepared above is cut a...

Embodiment 2

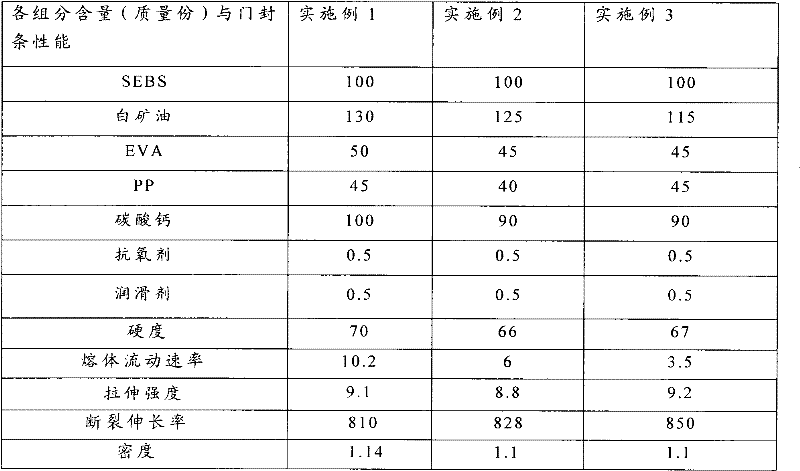

[0051] According to the method as in Example 1, TPE elastomer door seals were prepared by weighing the components in Example 2 in Table 1 below. And measure its index according to the method identical with embodiment 1.

[0052] The difference between this embodiment and Example 1 is that the antioxidant is two (2.4-di-tert-butylphenyl) pentaerythritol diphosphite, and the lubricant includes internal lubrication and external lubrication, selected from stearylamide , ethylene bis stearamide, erucamide, stearic acid, calcium stearate, the pigments are phthalocyanine green, phthalocyanine blue, titanium dioxide, carbon black and the like.

Embodiment 3

[0054] According to the method as in Example 1, TPE elastomer door seals were prepared by weighing the components in Example 3 in Table 1 below. And measure its index according to the method identical with embodiment 1. The difference between this embodiment and Example 1 is that the antioxidant is β (3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, and the lubricant includes internal lubrication and external lubrication. Lubricating, selected from stearamide, ethylene bisstearamide, erucamide, stearic acid, calcium stearate, the pigment is phthalocyanine green, phthalocyanine blue, titanium dioxide, carbon black and the like.

[0055] The content of each raw material and the main performance indicators of the TPE elastomer door seal made in Table 1 embodiment 1-3

[0056]

[0057] Table 2 Standards for the main performance indicators of TPE elastomer door seals

[0058] Test items

unit

technical indicators

Testing Standard

density

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com