Biological affinitive hydrophilic modified magnetic filler

A hydrophilic modification and affinity technology, applied in biological water/sewage treatment, sustainable biological treatment, chemical instruments and methods, etc., which can solve the problem of the starting speed of microbial film hanging, the amount of film hanging and the tightness of film and filler. And the problems of insufficient microbial cell activity and oxygen utilization, surface wetting of biological fillers, poor mass transfer performance and microbial adhesion and growth performance, and poor hydrophilic performance and bioaffinity, etc. The effect of water performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

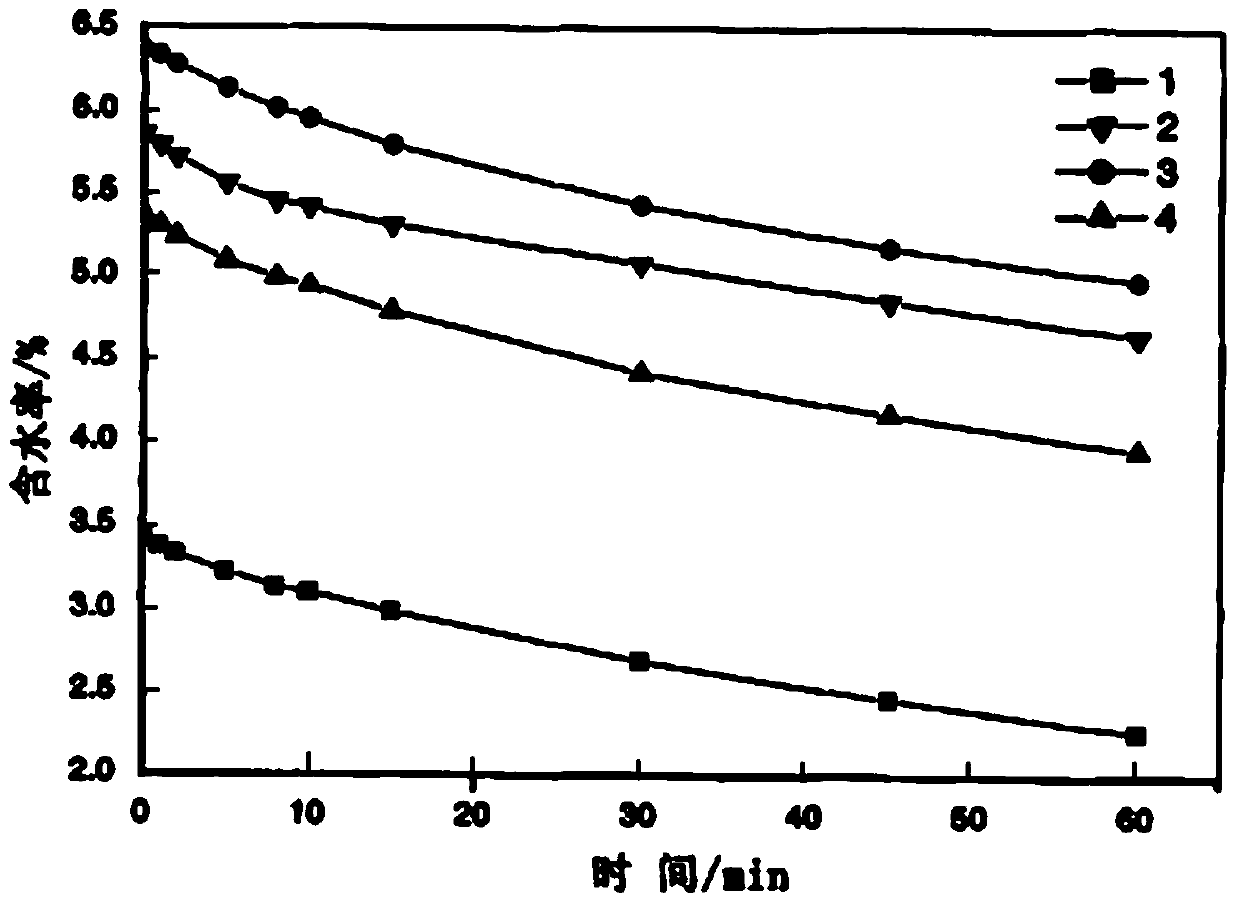

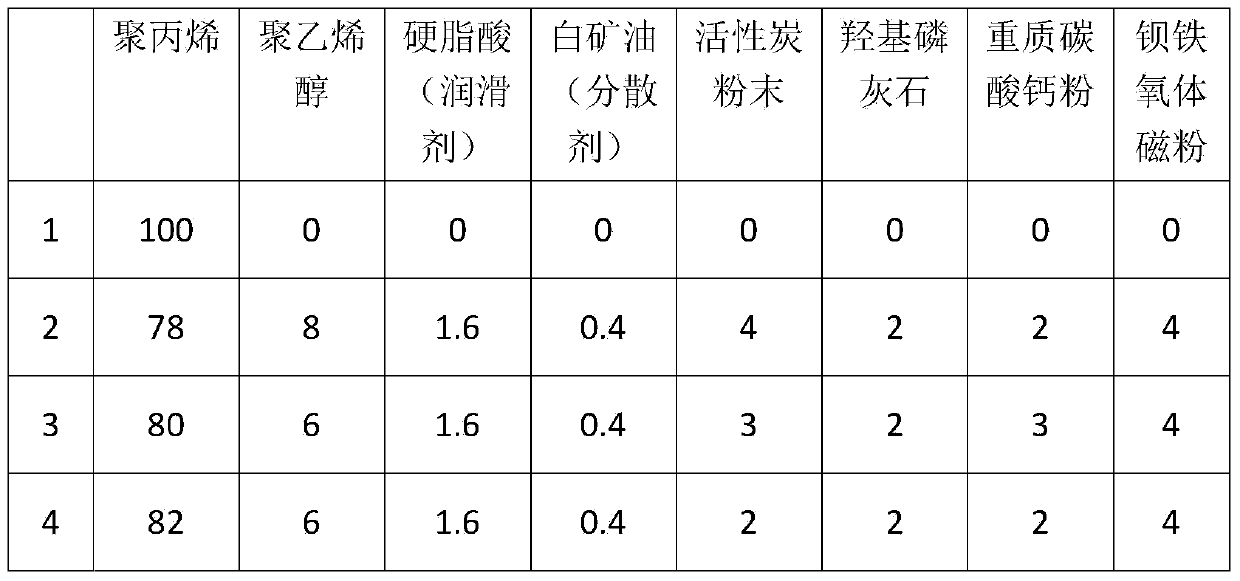

Embodiment 1

[0035] This example is to test the hydrophilicity of the above-mentioned four kinds of fillers with different proportions. Within the range of the proportioning relationship of each component of the bio-affinity and hydrophilic modified magnetic seed filler, three kinds of bio-affinity and hydrophilic modified magnetic seed fillers and a traditional polypropylene filler with different proportion formulas were selected. The relationship is shown in Table 1. The above four kinds of fillers with different formulations were put into the H / O method biochemical treatment system to carry out the whole process treatment of the refractory biodegradable wastewater in a chemical plant, and the biological affinity and hydrophilic modified magnetic seed fillers compared with the traditional polypropylene Hydrophilicity and water content of fillers. The main components of the wastewater to be treated are three monomers (dimethyl isophthalate-5-sodium sulfonate) and homologues, methanol, th...

Embodiment 2

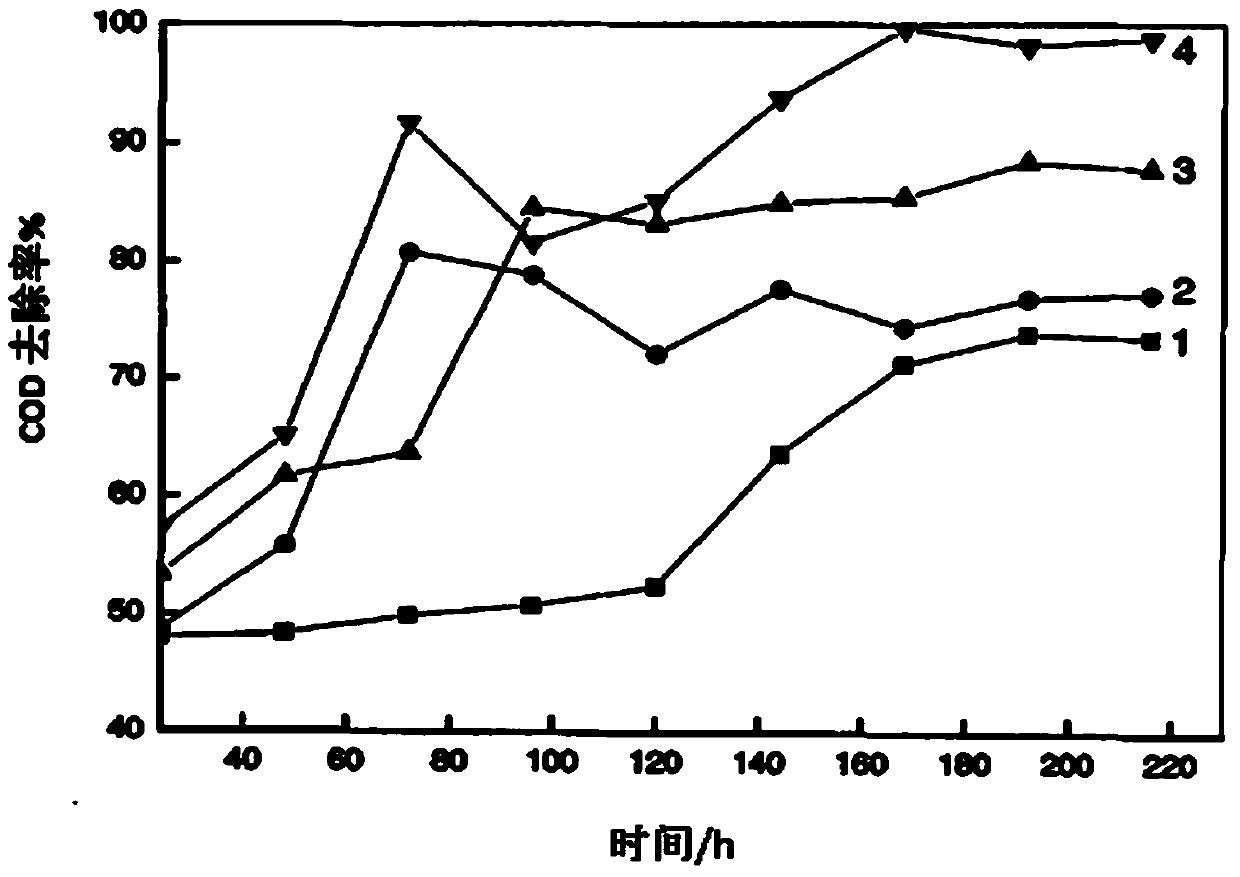

[0041] This embodiment is to test the film-forming speed, film-forming amount and COD removal rate of the bio-affinity and hydrophilic modified magnetic seed filler. After immersing the four different fillers in Example 1 in water for a period of time, after carrying out the film-hanging experiment, it was found that in less than 2 days, the modified No. 2-4 bio-affinity and hydrophilic modified magnetic There is gray-white biofilm attached to the surface of the filler, especially No. 4 biofill has the most film formation, while the traditional No. 1 polypropylene filler will have obvious signs of film formation after 7 to 9 days. After the film was stabilized, the aeration rate was increased, and it was found that the modified filler was more resistant to the impact of aeration load than the unmodified filler, and the biofilm adhesion on the No. 4 filler was also the best, and it was difficult to fall off.

[0042] The measurement results of COD removal rate in the film-hangi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com