Preparation method for non-silicon antifoaming agent

A non-silicon defoamer and organosilicon technology, which is applied in the field of preparation of non-silicon defoamers, can solve the problems of complicated process and slow defoaming speed, and achieve the advantages of simple preparation method, low production cost and stable foam suppression performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The method for preparing the non-silicon defoamer of the present invention is as follows: first, add 75 parts of white mineral oil, 7.5 parts of white carbon black, 7.5 parts of polyether, and 3 parts of fatty acid amide into a reaction kettle equipped with a stainless steel stirrer, a motor and a heating system , 4.5 parts of simethicone oil, 2.5 parts of thickener, mix evenly, and then raise the temperature to 120°C for 3 hours; keep stirring at room temperature and discharge to obtain ointment;

[0021] Take 80 parts of the prepared ointment, add self-emulsifying silicone oil, 20 parts of phosphate ester, 5 parts of emulsifier XP-50, SP-80, stir well, then add 280 parts of water to make phase inversion, and the phase inversion is complete Then add 16 parts of thickener AT-70 to thicken and adjust the viscosity to 1500CS~2000CS, and then discharge and pack.

[0022] The white mineral oil in the raw material has a viscosity of 5CS; the white carbon black has a specific...

Embodiment 2~4

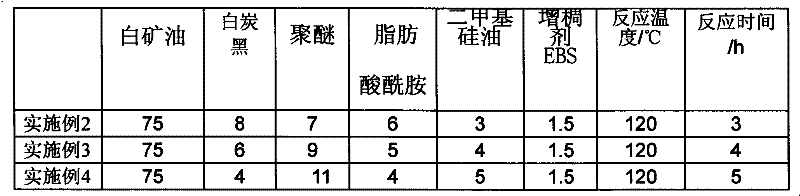

[0024] Compared with Example 1, the production process of Examples 2-4 is the same and will not be repeated. The proportioning, reaction time and temperature of each component in each embodiment are shown in Table 1 below.

[0025] Table 1 Case 2-4 Material ratio of ointment

[0026]

[0027] Table 2 Case 2-4 material ratio

[0028] Example 2

Example 3

Example 4

Ointment

80

80

80

self milking silicone oil

15

10

5

25

30

35

Emulsifier XP-50

5

5

5

Emulsifier SP-80

5

5

5

Thickener AT-70

16

16

16

water

280

280

280

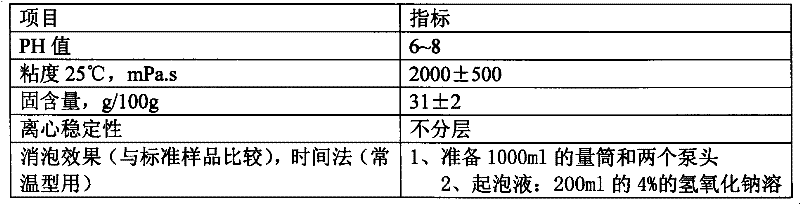

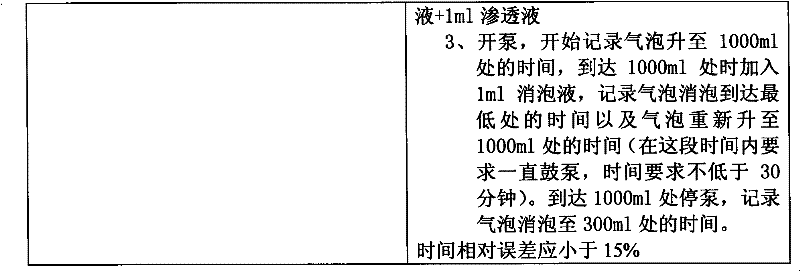

[0029] The performance of non-silicon defoamer of the present invention;

[0030] The product obtained in Example 1, the non-silicon defoamer, was tested according to the following standards, and the appearance was milky white and uniform liquid without mechanical impurities, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com