Lubricant For Conveyor Chains For Packaged Products

a technology of conveyor chains and lubricants, which is applied in the direction of conveyor parts, cleaning, petroleum industry, etc., can solve the problems of accelerated wear of conveyor chains, low process performance, and more noise and discontinuity in the feeding or supply of containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The characteristic details and composition of the lubricant for conveyor chains of bottled products are described in the following paragraphs, in order to define the characteristics and composition of said lubricant, without limiting the scope of this description.

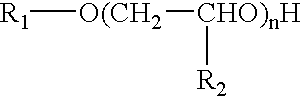

[0022]The lubricant for conveyor chains of bottled products according to the invention shows components that in turn could consist of multiple components.

[0023]The components are described separately hereunder, without necessarily being described in an order of importance.

Component I

[0024]The lubricant for conveyor chains of bottled products contains a component I that consists of one or more silicon fluids. The silicon fluids, silicones or silicone states designate the totality of complete synthetic products whose molecules are constituted by atoms alternated between silicon and oxygen, to which various organic radicals can be added, in fact, the silicon molecules are chains of silicon and oxygen atoms, so that the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction | aaaaa | aaaaa |

| concentrations | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com