Nano composite aqueous epoxide resin coating material and preparation method

A water-based epoxy resin and nano-composite technology, applied in epoxy resin coatings, coatings, etc., can solve the problems of high price, environmental pollution, and urgent water-based epoxy resin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

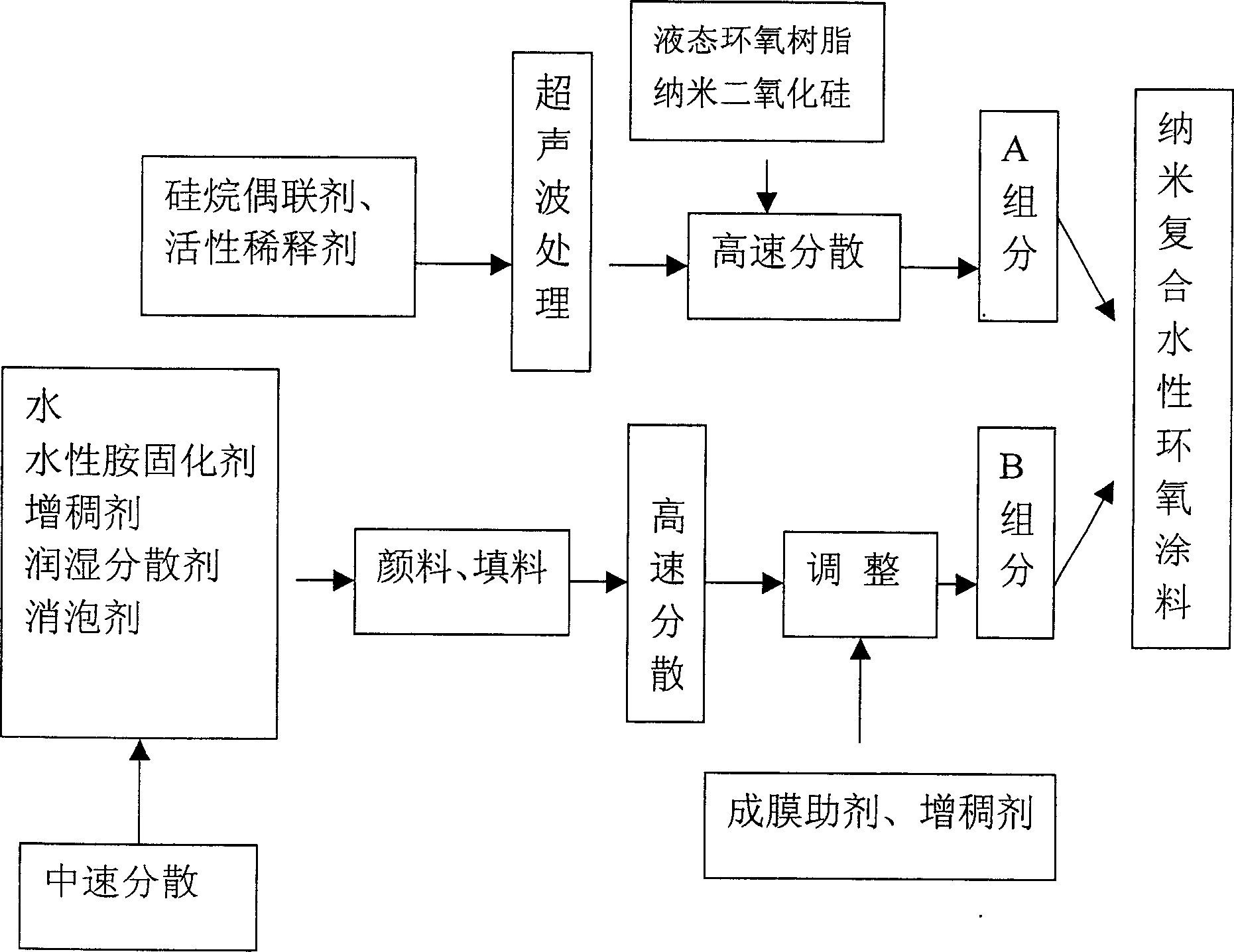

Method used

Image

Examples

Embodiment 1

[0089] Nanocomposite water-based epoxy resin coating material, which is composed of epoxy components and water-based amine curing agent components. The epoxy components include: epoxy resin, reactive diluent, nano-silica particles, and silane coupling agent; The components of water-based amine curing agent include: water-based amine curing agent, wetting and dispersing agent, defoamer, pigment, filler, film-forming aid, thickener, and water.

[0090] Through a large number of tests, the percentage by weight (wt %) of each component of the optimum formula of coating of the present invention is: epoxy resin EPON 828 is 18.5%, active diluent is 1.9%, nano-silica is 0.5%, the amount of γ-glycidyl etheroxypropyl trimethoxysilane is 4%-6% of the amount of nano-silica particles, EPI- CURE 8535-W-50 is 9.0%, wetting and dispersing agent SURFYNOL SE-F is 0.7%, defoamer SURFYNOL DF75 is 0.5%, thickener Detron VT-819 (1% solution) is 1.0%, rutile titanium dioxide is 1-5%, heavy c...

Embodiment 2

[0098] The weight percent (wt%) of each component of coating of the present invention is: epoxy resin is 20%, tert-butylphenyl glycidyl ether is 3%, nano silicon dioxide is 3%, γ-glycidyl ether oxypropyl methyl The amount of diethoxysilane is 4%-6% of the amount of nano-silica particles, EPI-CURE 8535-W-50 is 10%, wetting and dispersing agent SURFYNOL SE-F is 0.5%, defoamer SURFYNOL DF75 is 0.3%, thickener Detron VT-819 (1% solution) is 0.8%, rutile titanium dioxide is 4%, heavy calcium is 15%, mica powder is 10%, barium sulfate is 16%, film-forming aid is 1.0%, and the rest is water.

[0099] The preparation method is the same as Example 1.

Embodiment 3

[0101] The weight percent (wt%) of each component of coating of the present invention is: epoxy resin is 30%, tert-butylphenyl glycidyl ether is 1%, nano silicon dioxide is 2%, propylene oxide butyl ether or benzene The amount of glycidyl ether is 4%-6% of the amount of nano-silica particles, EPI-CURE 8535-W-50 is 12%, wetting and dispersing agent SURFYNOL SE-F is 0.3%, defoamer SURFYNOL DF75 is 0.8%, thickener Detron VT-819 (1% solution) is 0.3%, rutile titanium dioxide is 1%, heavy calcium is 10%, mica powder is 5%, barium sulfate is 25%, film-forming aid is 1.6%, and the rest is water.

[0102] The preparation method is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com