A kind of glue type traditional Chinese medicine instant preparation and its non-adjuvant direct compression technology method

An excipient-free, instant technology, applied in pharmaceutical formulations, drug combinations, unknown raw materials, etc., can solve the problems of less than 20% utilization rate of powder direct tableting process, unable to meet the needs of packaging, storage and transportation, and poor product brittleness. The effect of enhancing immunity, high brittleness, and low powder drop rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take the donkey-hide gelatin coarse powder, place it in a pulverizer, pulverize and sieve to obtain 40-60 mesh donkey-hide gelatin powder;

[0036] The ethanol (wetting agent) of 90% volume concentration is added in donkey-hide gelatin powder with the consumption of 20% to make soft material, seal and infiltrate 4min, adopt briquetting machine to press into briquette, the host speed of described briquetting is 4r / min, and filling speed It is 15 times of the speed of the main machine; the filling depth is 8mm, the main pressing thickness is 6mm, and the pre-pressing thickness is 1.6 times of the main pressing thickness. The upper and lower punches of the tablet are sprayed and pre-coated with alcohol at the position before contacting the sample: the alcohol concentration is 93%, and the atomization area is 770mm 2 , the spray volume is 0.35ml / time. After tableting, vacuum-dry at 30° C. with a vacuum degree of 0.03 MPa for 80 minutes to obtain donkey-hide gelatin instant...

Embodiment 2

[0045] Take the donkey-hide gelatin coarse powder, put it in a pulverizer, pulverize and sieve to obtain 40-60 mesh donkey-hide gelatin powder;

[0046] The ethanol (wetting agent) of 90% volume concentration is added in donkey-hide gelatin powder with the consumption of 20% to make soft material, seal and infiltrate 4min, adopt briquetting machine to press into briquetting, the host speed of described briquetting is 5r / min, and filling speed It is 75r / min; the filling depth is 8mm, the main pressing thickness is 6mm; the pre-pressing thickness is 1.6 times of the main pressing thickness. In the present invention, the upper and lower punches of the tablet use alcohol to carry out spray pre-coating at the position before contacting the sample: the alcohol concentration is 93%, and the atomization area is 780mm 2 , the spray volume is 0.3ml / time. After tableting, vacuum-dry at 30° C. with a vacuum degree of 0.03 MPa; vacuum-dry for 60 minutes to obtain donkey-hide gelatin insta...

Embodiment 3

[0056] Take the donkey-hide gelatin coarse powder, place it in a pulverizer, pulverize and sieve to obtain 50-60 mesh donkey-hide gelatin powder;

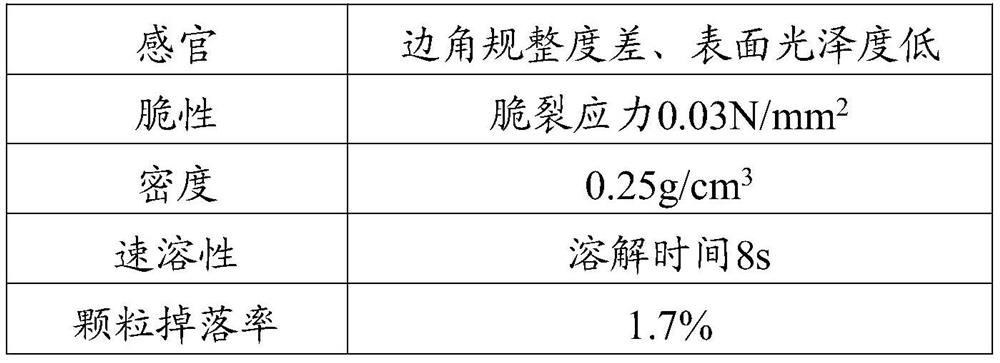

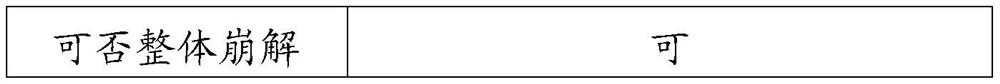

[0057] The ethanol (wetting agent) of 91% volume concentration is added in donkey-hide gelatin powder with the consumption of 20% to make soft material, seal and infiltrate 4min, press into agglomerate, the host speed of described briquetting is 6r / min, and the filling speed is 1 / 2 of the host speed. 15 times; the filling depth is 9mm, the main pressing thickness is 7mm, and the pre-pressing thickness is 1.6 times of the main pressing thickness. The upper and lower punches of the tablet are sprayed and pre-coated with alcohol at the position before contacting the sample: the alcohol concentration is 93%, and the atomization area is 760mm 2 , the amount of spraying is 0.4ml / time, after tableting, vacuum-dry at 40°C with a vacuum degree of 0.04Mpa, and vacuum-dry for 80min to obtain instant donkey-hide gelatin blocks. The prepared d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com