Durable soft quick-drying terry fabric and production method thereof

A terry and fabric technology, applied in the direction of fabric, knitting, weaving, etc., can solve the problems of disordered terry structure, affecting the uniform shrinkage of filaments, difficult to mass production, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

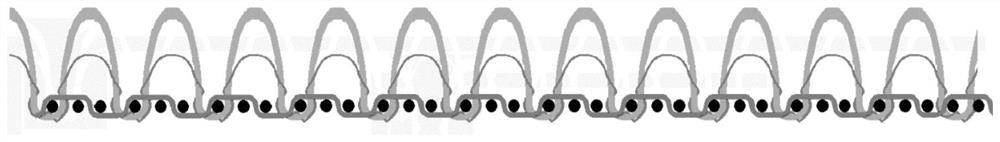

Image

Examples

Embodiment 1

[0047] Take woven terry fabric as an example:

[0048] (1) The composition of the terry yarn is: fine count yarn DTY type regenerated polyester yarn, coarse count yarn 100% cotton;

[0049] (2) Coarse yarn count of terry yarn: 97.2tex or 6s, fine yarn 3.33tex / 24FDTY or 30D / 24FDTY;

[0050] (3) The coarse yarn twist of the pile yarn is 30t / dm, the corresponding twist coefficient is 295.8, and the twist direction of the coarse yarn is Z twist.

[0051] (4) Coarse yarn and fine count yarn of terry yarn are paralleled and twisted to form the terry yarn, the twist of the ply yarn is 10t / dm, and the twist direction is S direction.

[0052] (5) the ground warp yarn of the towel fabric is 24s / 2, and the weft yarn is 16s;

[0053] (6) Warp the 24s / 2 ground warp yarn and the 6s / 30D ply looped terry yarn of the towel fabric respectively to form a ground warp beam and a loop warp beam respectively. Ground warp and weft are pure cotton

[0054] (7) Sizing the warp beams formed in step ...

example 2

[0069] Take woven terry fabric as an example:

[0070] (1) The composition of the terry yarn is: fine count yarn DTY type regenerated polyester yarn, coarse count yarn 100% cotton

[0071] (2) Coarse yarn count of terry yarn: 27.8tex or 21s, fine yarn 8.33tex / 144F DTY or 75D / 144FDTY,

[0072] (3) The coarse yarn twist of the pile yarn is 50t / dm, the corresponding twist coefficient is 263.6, and the twist direction of the coarse yarn is Z twist.

[0073] (4) Coarse yarns and fine count yarns of the terry yarn are paralleled and twisted to form the terry yarn, the ply twist is 30t / dm, and the twist direction is S direction.

[0074] (5) The ground warp yarn of the terry fabric is 32s / 2, the weft yarn is 21s, and the ingredients are all pure cotton.

[0075] (6) Warping the 32s / 2 ground warp yarn and the 21s / 150D ply terry yarn of the terry fabric to form a ground warp axis and a pile warp axis respectively.

[0076] (7) Sizing the warp beams formed in step (6) to form ground ...

Embodiment 3

[0090] Take woven terry fabric as an example:

[0091] (1) The composition of the terry yarn is: fine-count yarn DTY type nylon yarn, coarse-count yarn 100% cotton

[0092] (2) The coarse yarn count of the pile yarn is: corresponding to 48.6tex or 12s, and the fine yarn 5.56tex / 48F or 50D / 48FDTY,

[0093] (3) The coarse yarn twist of the pile yarn is: 35t / dm, the corresponding twist coefficient is 244, and the twist direction of the coarse yarn is Z twist.

[0094] (4) Coarse and fine yarns of pile yarn are paralleled and twisted to form the pile yarn, the ply twist is 26t / dm, and the twist direction is S direction.

[0095] (5) The ground warp yarn of the terry fabric is 24s / 2, and the weft yarn is 16s, both of which are pure cotton yarns.

[0096] (6) Warping the 24s / 2 ground warp yarn and the 12s / 50D ply terry yarn of the terry fabric to form a ground warp axis and a pile warp axis respectively.

[0097] (7) Sizing the warp beams formed in step (6) to form ground warp be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com