Melt-blown polypropylene composition as well as preparation and application thereof

A melt-blown polypropylene and composition technology, applied in the field of melt-blown polypropylene composition and its preparation, can solve the problems of reducing the effective barrier effect of masks, unable to form a fiber filter layer, weakening electrostatic adsorption capacity, etc., to ensure long-term effect. The effect of filtering efficiency, improving charge trapping ability, and reducing interfacial free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

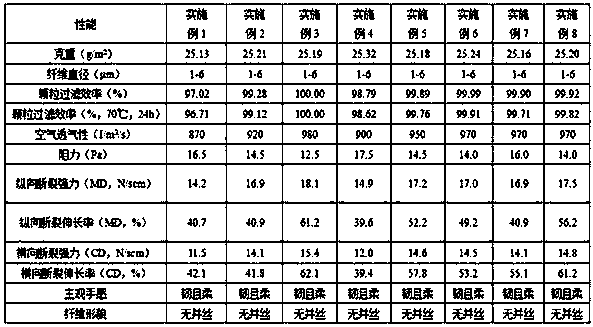

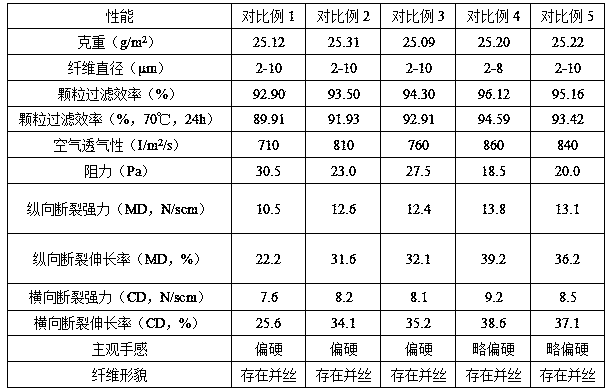

Examples

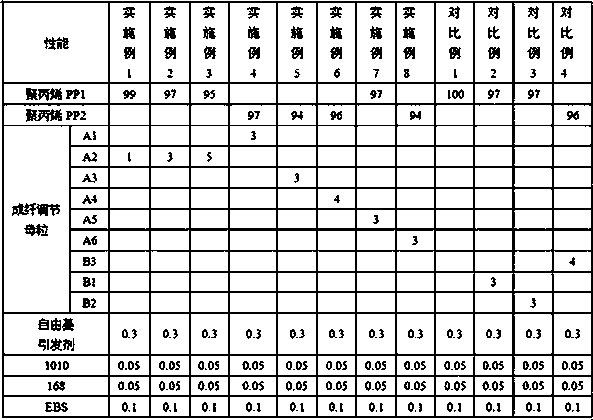

Embodiment 1-8 and comparative example 1-4

[0064] (1) Press the proportioning of Table 1, after weighing each component in proportion, extrude the strands and pelletize through the twin-screw extruder to obtain the fiber-forming masterbatch;

[0065] (2) According to the ratio in Table 2, the prepared fiber-forming adjustment masterbatch and other components were mixed evenly in proportion, and the melt-blown polypropylene composition was obtained by extruding strands and pelletizing through a twin-screw extruder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com