Patents

Literature

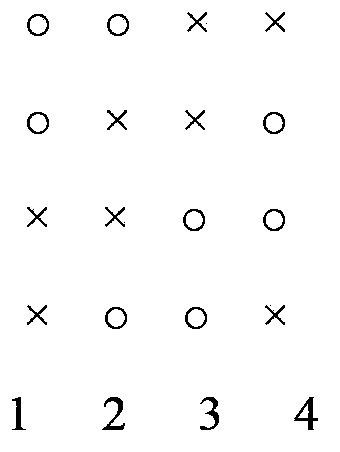

32results about How to "Good physical index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

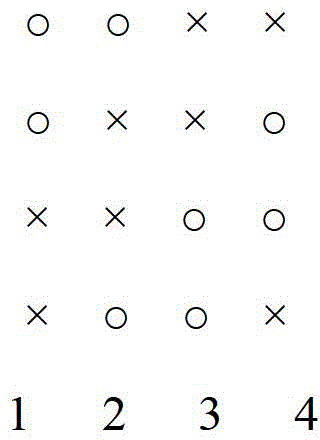

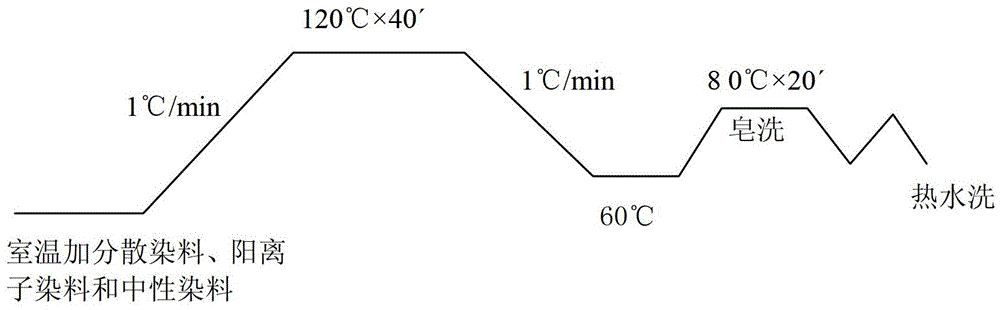

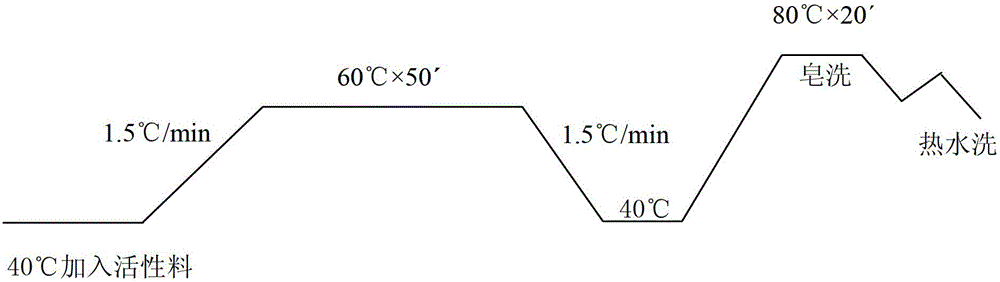

Low-wool-content multi-component chemical fiber blended fabric and preparing method thereof

ActiveCN103835048AImprove perceptionEasy to takeSucessive textile treatmentsWoven fabricsPolyesterPolymer science

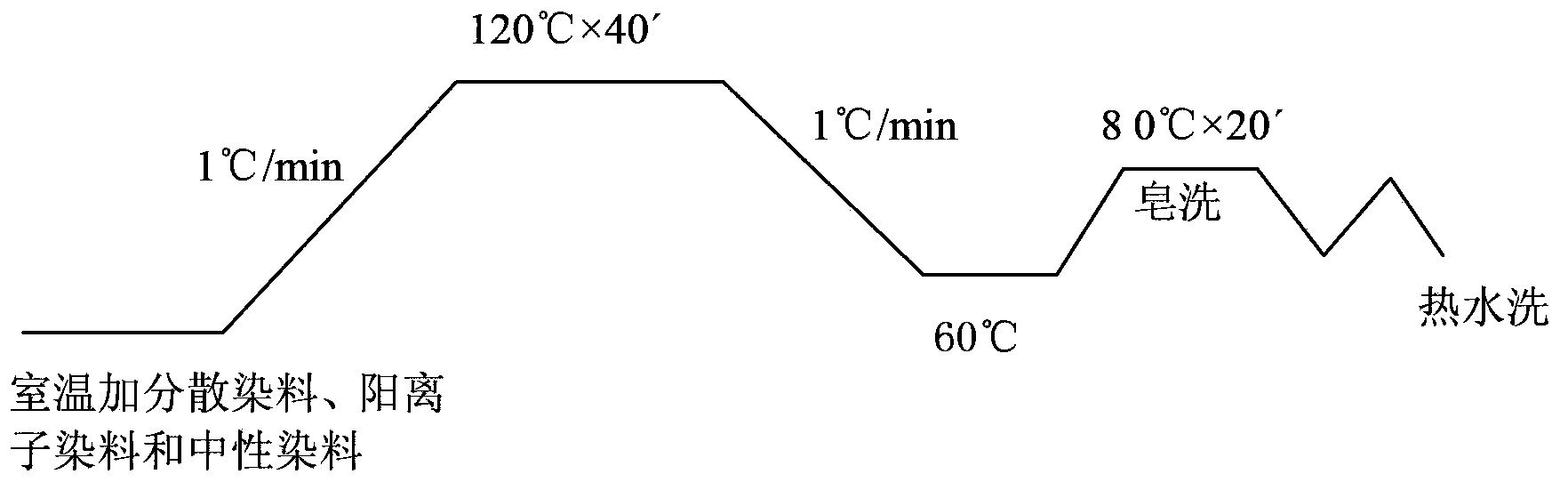

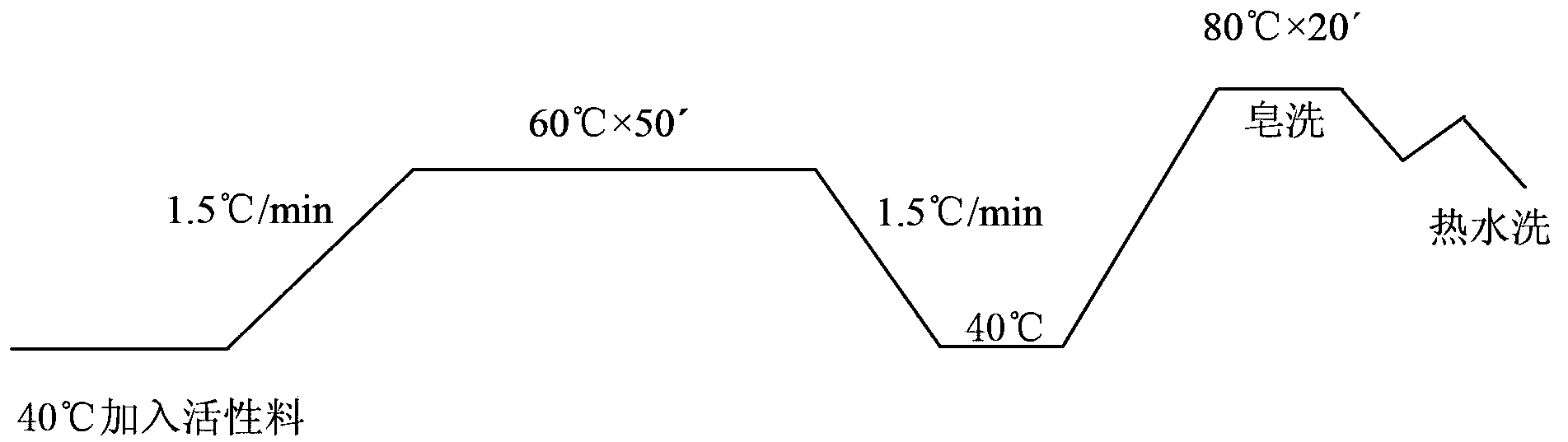

The invention provides a low-wool-content multi-component chemical fiber blended fabric and a preparing method of the low-wool-content multi-component chemical fiber blended fabric and belongs to the field of spinning dyeing and finishing. Wool is added to multi-component chemical fibers and the low-wool-content multi-component chemical fiber blended fabric comprises, by weight, 30% to 40% of polyester staple fibers, 20% to 30% of modified polyester fibers, 10% to 20% of mucilage glue, 5% to 15% of Tencel, 8% to 30% of the wool and 0.1% to 0.6% of conductive fibers. The wool content of a traditional product is changed, wool fibers with the content smaller than 30% are blended with the polyester staple fibers, the modified polyester fibers, the mucilage glue, the Tencel and the conductive fibers in the chemical fibers in a combined mode, so that mutual advantage complement of the various fibers is achieved, and multiple colors, the high comfort degree and the easy-maintenance performance of the fabric are achieved with the low wool content. The technology is reasonable, the technical purpose of one bath dyeing of the wool and the multi-component chemical fibers is effectively achieved, and a new path is created for upgrading orientation and the comfort of chemical fiber fabric.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

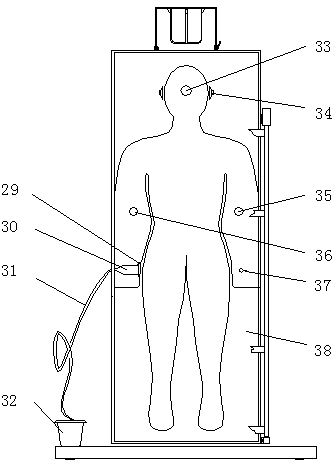

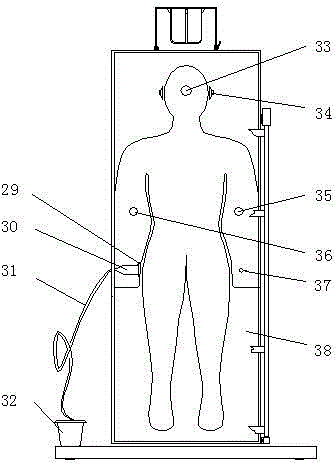

Intelligent health-preserving bed

InactiveCN103222753AImprove breathabilityGood warmth retentionStuffed mattressesSpring mattressesEngineering

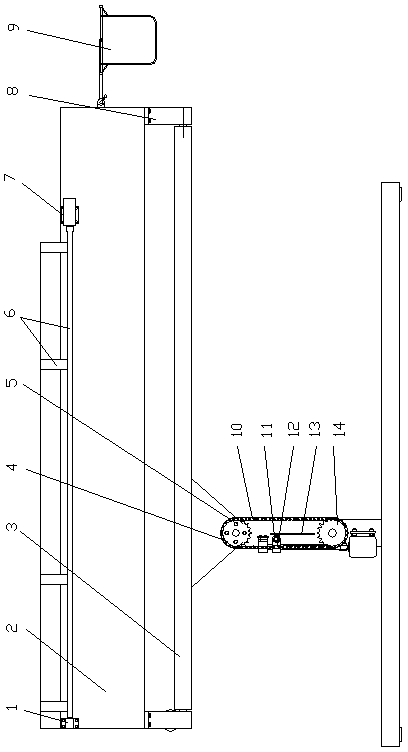

Provided is an intelligent health-preserving bed. A bed body rotates opposite to a rockshaft to form a revolving bed body and the revolving bed body conducts intelligent longitudinal rotation. A quilt supporting mechanism is installed at the upper portion of the revolving bed body, and therefore automatic covering and uncovering of a quilt can be achieved. A drinking cup balancing support is connected with a horizontal end face of the revolving bed body in a fastening mode, and therefore the intelligent health bed is convenient for people to drink. A thermostatic control module is arranged inside the revolving bed body and has the functions of temperature detection and adjustment, and therefore automatic constant temperature is achieved. A urine cup mechanism is arranged at the lateral portion inside the revolving bed body, therefore, the intelligent health cup is convenient for people to urinate, and automatic sealing of the urine cup mechanism is achieved. A playing device is arranged inside the revolving bed body, and therefore music playing is achieved and awakening ringing tones are provided. A bed body control part is a control core of the intelligent health bed and controls rotating of the revolving bed body, covering and uncovering of the quilt supporting mechanism, temperature adjusting of the thermostatic control module, and playing of the media player. The intelligent health-preserving bed is scientific in structure, comfortable in use and free to control.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Diamond glaze for ceramic tiles

The invention provides a diamond glaze for ceramic tiles.One), a formula comprises: spodumene powder, frit powder, potassium feldspar powder, calcined talc powder, barium carbonate powder, wollastonite powder, kaolin powder, white alundum powder, and zinc oxide; two), a preparation method comprises the steps: 1, preparing the frit powder, potassium feldspar, wollastonite, raw talc, barium carbonate, calcite, quartz, crude aluminum oxide, 95 zinc oxide, potassium carbonate and strontium carbonate, 1), placing all materials in a melting furnace, and heating to 1500 DEG C to obtain frit; 2), taking out for cooling to normal temperature, crushing, screening with a 100-mesh screen for use, and if disqualification occurs, crushing and screening until qualification; 2, placing all materials of formula one) into a stirrer, and stirring well to obtain the diamond glaze.The method has a simple process, the diamond glaze has high glaze, can prevent cracking, cut facture and the like, has excellent wear resistance and is useful in the production of polished tiles closer to nature and richer in color.

Owner:XIANGYANG GAOMING MINING IND CO LTD

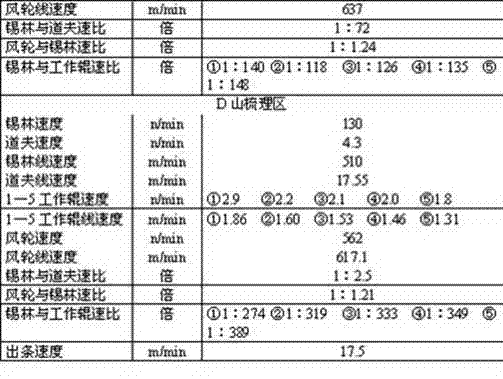

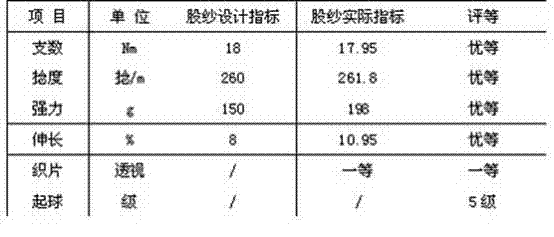

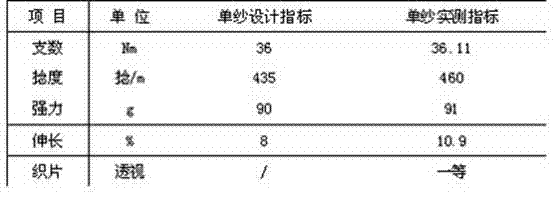

Cashmere-Apocynum venetum roving blended yarn and production method thereof

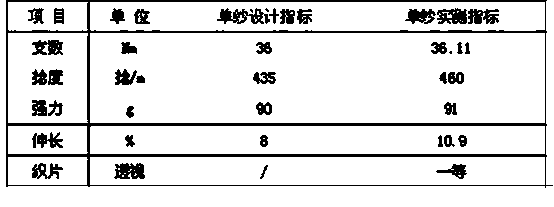

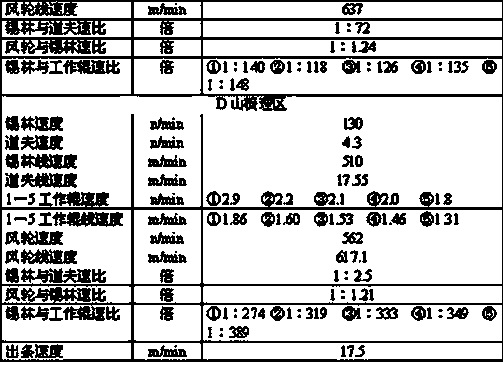

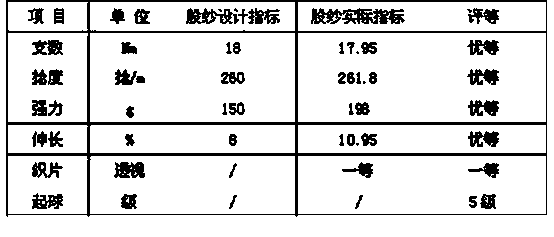

The invention relates to cashmere-Apocynum venetum blended yarns. The number of roving yarns is 28-36Nm, and the raw material proportioning is as follows: 30% of Apocynum venetum and 70% of cashmere, wherein the twist degree is 380 / 230-435 / 260 twist / m, the strength is 100 / 160-90 / 150g, and the elongation at break is 8%. The production method for the yarns comprises the steps of extracting and fine-combing the Apocynum venetum and then blending the treated Apocynum venetum with the cashmere; the Apocynum venetum extracting process comprises the steps of carrying out Aapocynum venetum peeling, impurity removing, biological enzyme degumming, water washing, drying, oiling, drying on Apocynum venetum stalks, and then obtaining refined dry Apocynum venetum; the Apocynum venetum fine-combing process comprises the following steps of carrying out nourishing, opening and slivering on the refined dry Apocynum venetum, and then obtaining fine-combing apocynum venetum; and the cashmere-Apocynum venetum blending process comprises the steps of carrying out blending oiling, nourishing, combing, spinning, spooling, doubling and double-twisting on the Apocynum venetum and cashmere fiber, to obtain finished products.

Owner:宁夏嘉源绒业集团有限公司

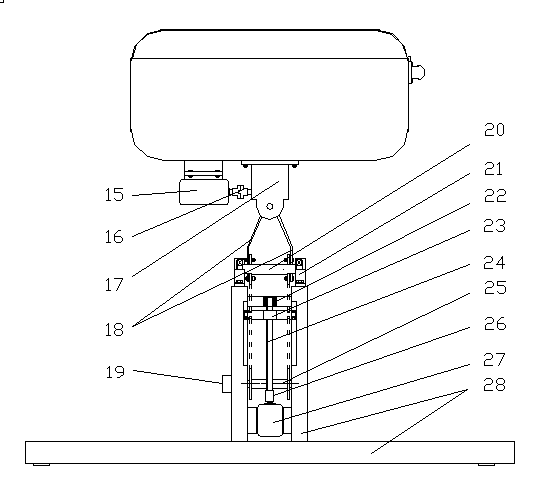

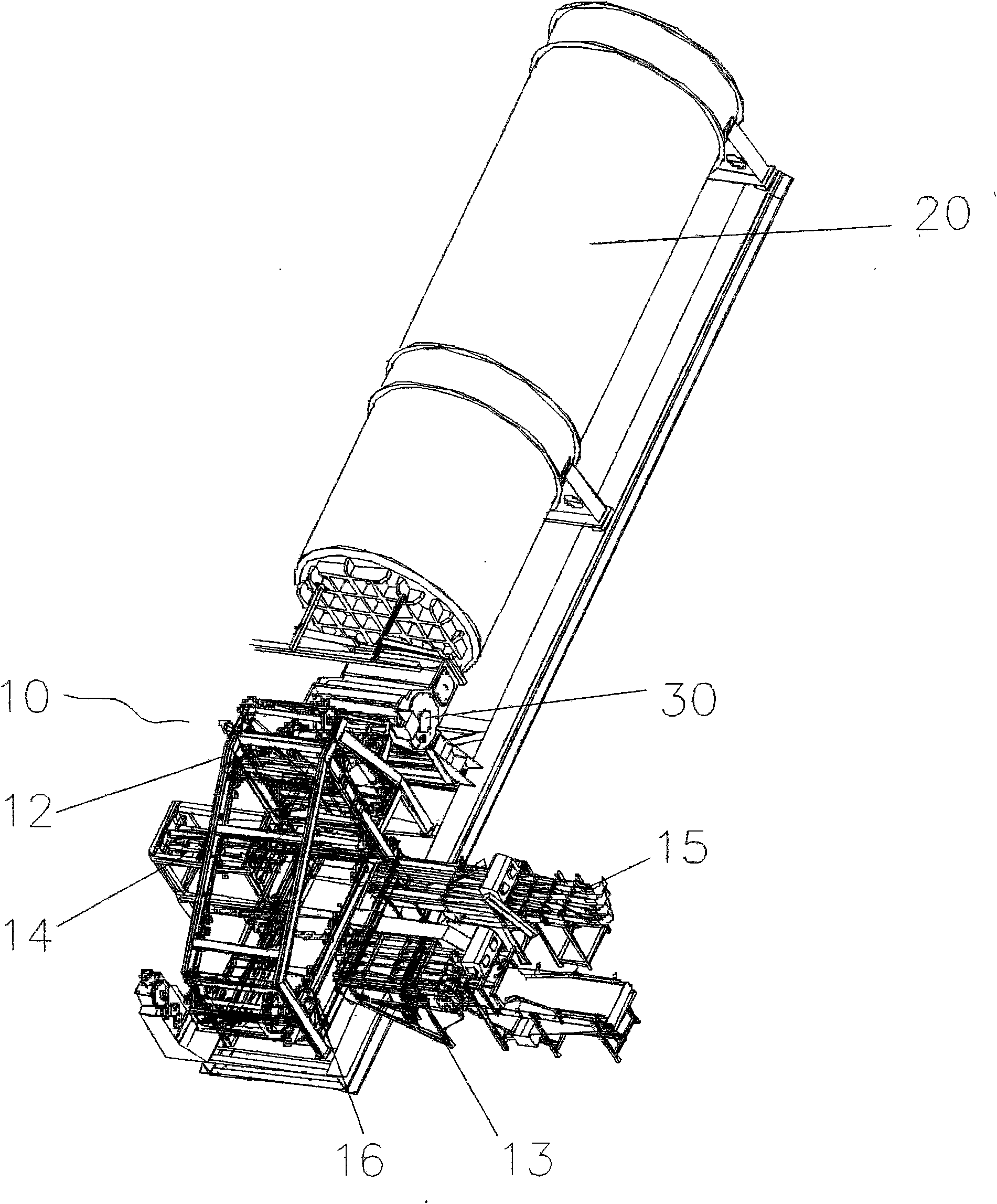

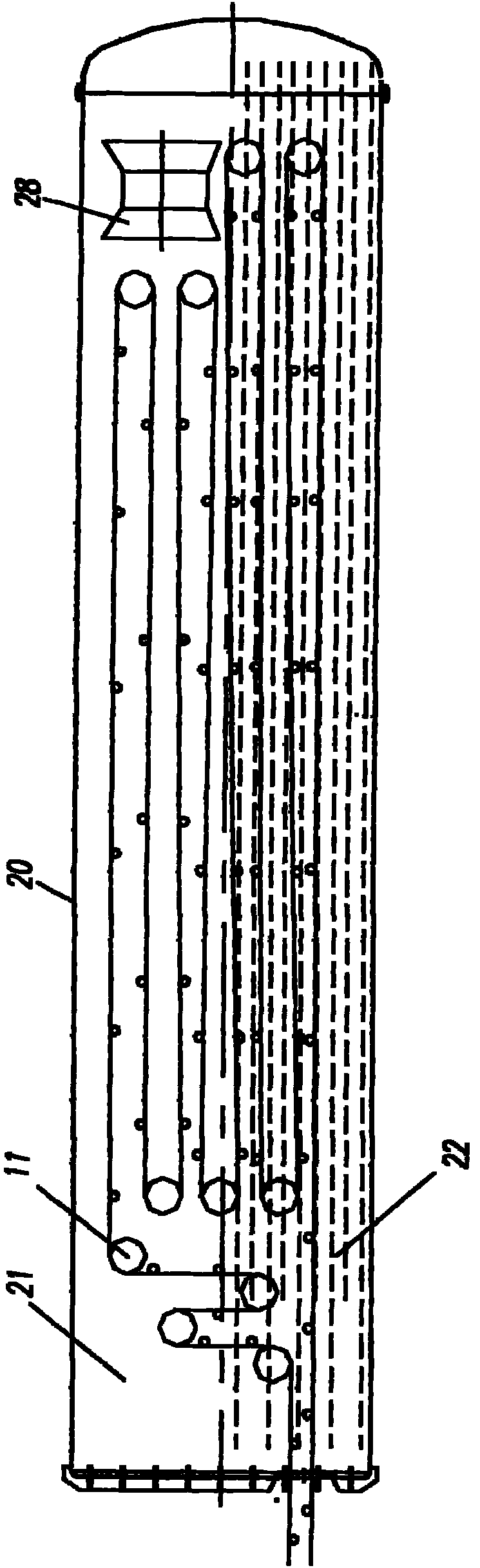

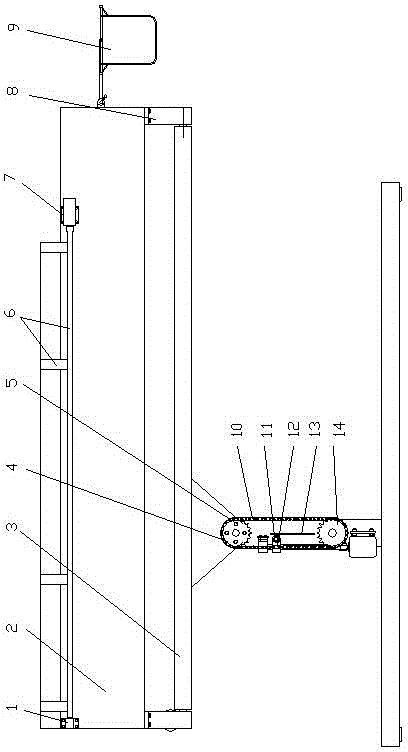

Methods for restoring ecosystem of alkali-saline grassland by adopting multifunctional vibration-type soil-improving machine

InactiveCN101697672AEnsure that the upper and lower levels remain unchangedDoes not destroy active ingredientsSoil-working methodsGrasslandLawn

The invention discloses methods for restoring an ecosystem of alkali-saline grassland by adopting a multifunctional vibration-type soil-improving machine, and relates to methods for restoring the ecosystem of the alkali-saline grassland. The methods solve the problems that the traditional methods for treating the alkali-saline grassland have high investment, slow response and single object and can only treat slight saline soil. The first method is to adopt vibration subsoiling to improve soil for slight alkali-saline grassland; the second method is to adopt vibration subsoiling and biochemical preparation spraying to improve the soil for medium alkali-saline grassland; and the third method is to adopt vibration subsoiling, biochemical preparation spraying and saline tolerant plant planting to improve the soil for severe alkali-saline grassland. The methods not only can save energy and reduce consumption, but also can improve the rate of soil pulverization, improve physical indexes of the soil, retain water, reduce alkali and salt, and inhibit accumulation of salt in the surface soil. By adopting the methods, the investment cost is reduced; and the methods have quick response, and can restore the slight alkali-saline grassland, the medium alkali-saline grassland and the severe alkali-saline grassland.

Owner:HEILONGJIANG PROVINCIAL HYDRAULIC RES INST

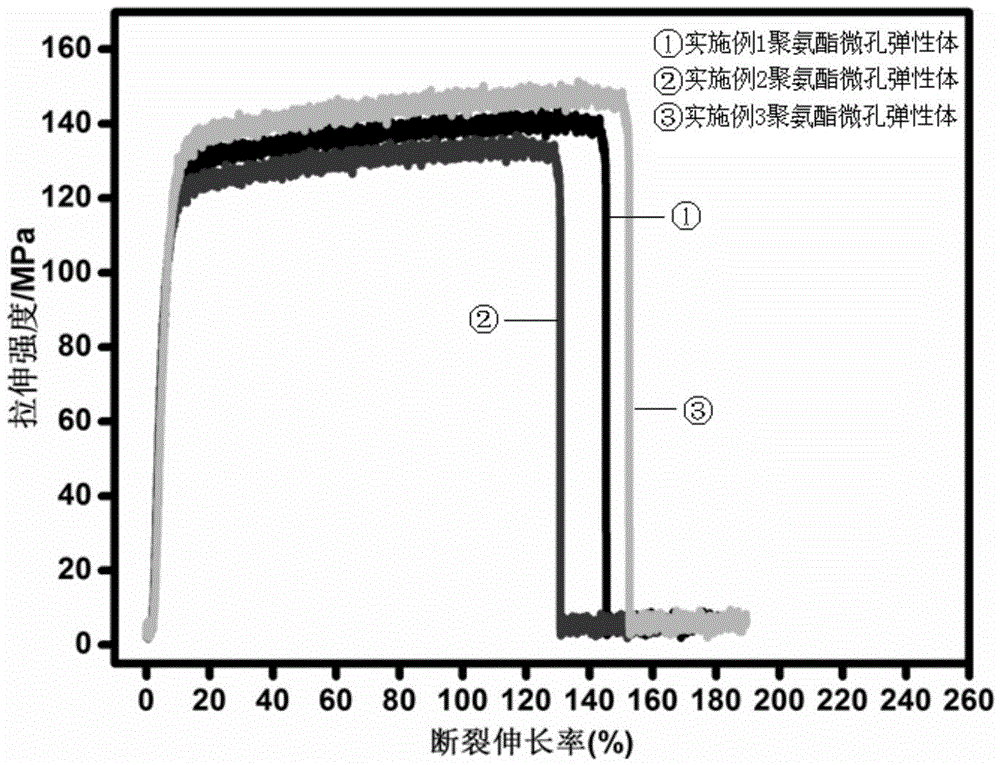

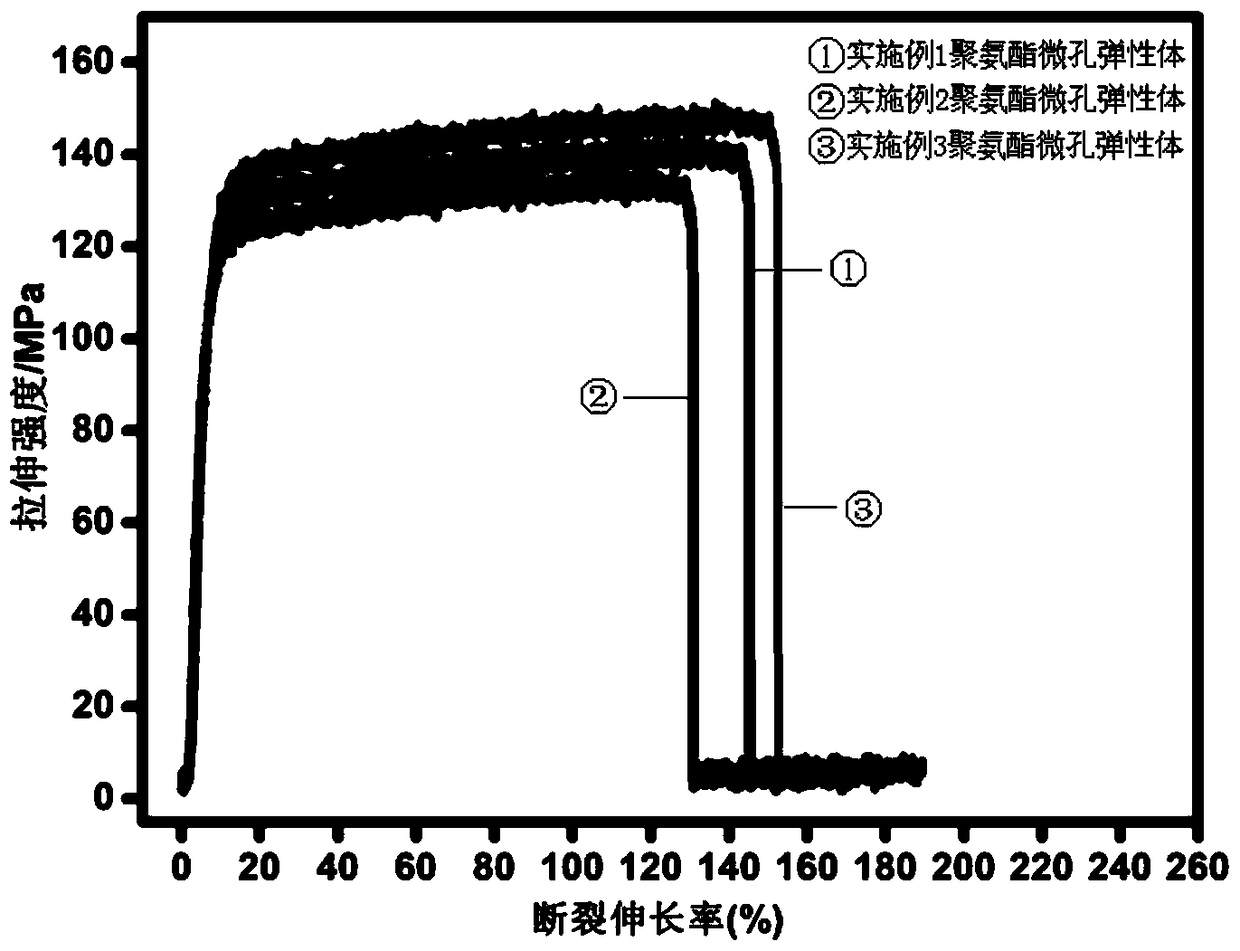

Polyether urethane material, method for preparing same and application of polyether urethane material

ActiveCN105566625AStrong low temperature performanceStrong water resistancePolyurethane elastomerOrganic solvent

The invention provides a polyether urethane material. A method for preparing the polyether urethane material includes carrying out room-temperature reaction on polyhydric alcohol of initiators and alkylene oxide A in organic solvents under catalytic actions of alkali A for 1-30 h to obtain systems A; adding alkylene oxide B and metal sulfate into the systems A and carrying out room-temperature reaction on the alkylene oxide B, the metal sulfate and the systems A for 1-40 h to obtain systems B; adding alkylene oxide C and alkali B into the systems B, carrying out room-temperature reaction on the alkylene oxide C, the alkali B and the systems B for 1-60 h to obtain reaction mixtures and carrying out after-treatment on the reaction mixtures to obtain a finished product. The polyether urethane material and the method have the advantages that the polyether urethane material can be used for preparing polyurethane cellular elastomers which are used as shoe sole materials; the polyether urethane material is high in low-temperature performance, hydrolysis resistance and mildew resistance, the reaction time and the mold release time can be shortened when the polyether urethane material is used for preparing the polyurethane cellular elastomers, and the physical performance of the product can be improved.

Owner:薛立新

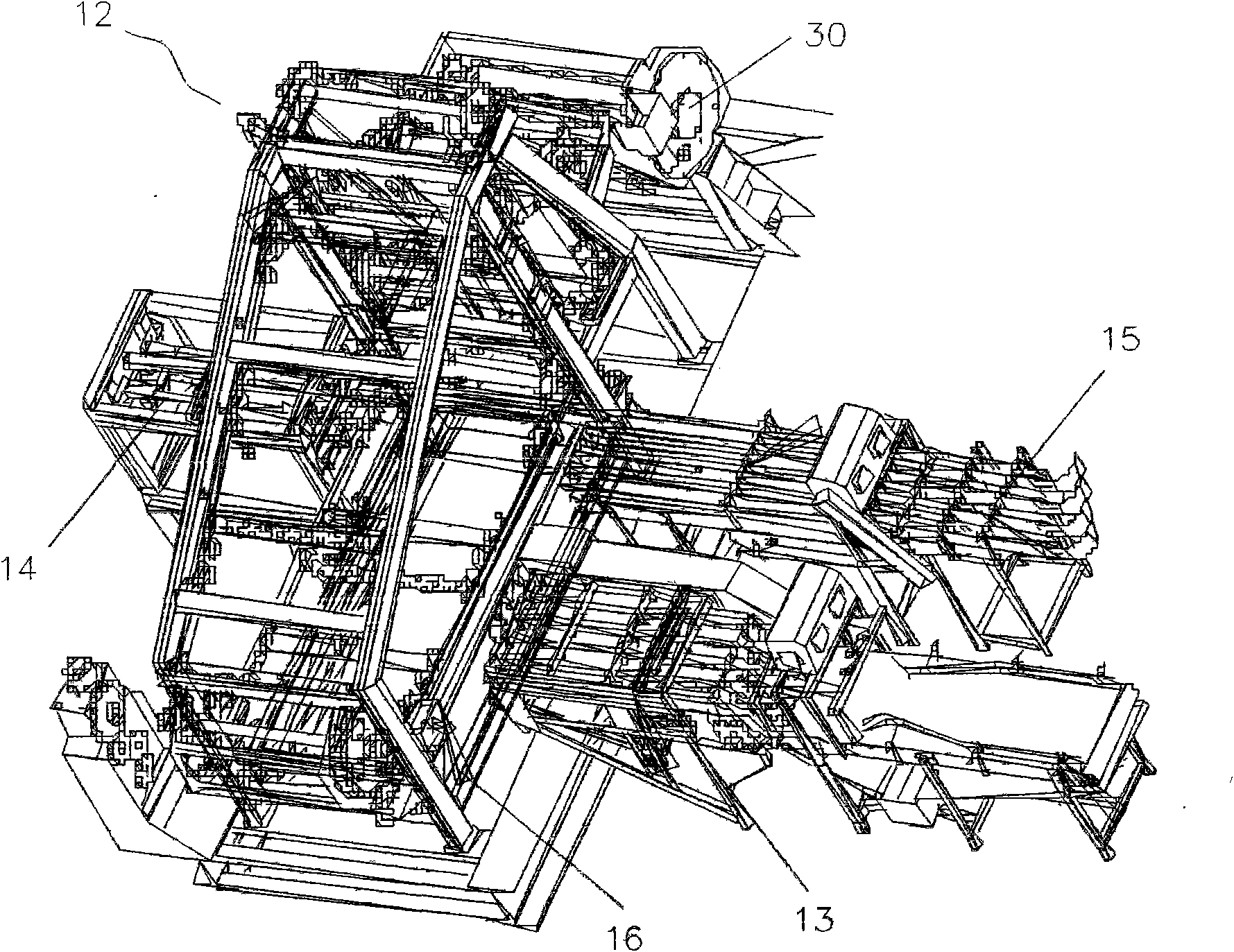

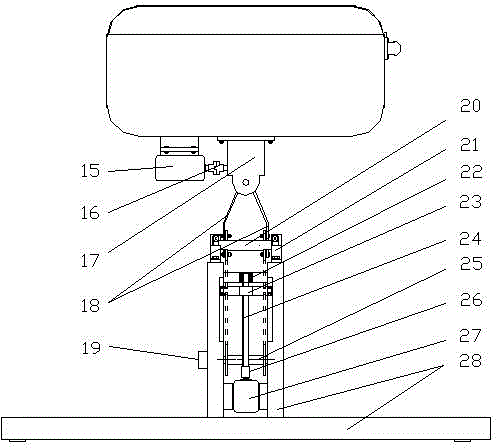

Continuous secondary sterilization machine

InactiveCN101884796AImprove the bactericidal effectRapid sterilizationFood preservationLavatory sanitoryEngineeringAutomation

The invention discloses a continuous secondary sterilization machine, at least comprising a conveying device and a sterilization device. The machine also comprises a water-tightseal device and an external steam circulation system, wherein the water-tightseal device is arranged at the opening of the sterilization device; the conveying device enters and exits the sterilization device through the water-tightseal device; the part of the conveying device, which is positioned inside the sterilization device and carries out continuous conveying is an internal transmission mechanism, and the part of the conveying device, which is positioned outside the sterilization device and carries out clearance halt type conveying, is an outer transmission mechanism; and the external steam circulation system provides sterilizing steam to the inside of the sterilization device. The machine of the invention ensures the secondary sterilization process to be continuous, removes mass heavy manual work, realizes full automation, and greatly improves the production efficiency.

Owner:上海伊本轻工机械有限公司

Nature bamboo fiber kitchen towels with high antibacterial property and preparation method

InactiveCN110565427AHigh strengthReserved naturePaper/cardboardPulping with inorganic basesHigh concentrationQuinone

The invention discloses nature bamboo fiber kitchen towels with high antibacterial property and a preparation method. The preparation method comprises the following steps: S1, washing bamboo sheets, removing impurities of the bamboo sheets and performing dehydration for subsequent use; S2, steaming and cooking the bamboo sheets by adopting an alkali method; S3, screening out bamboo joints and coarse fiber bundles of pulps which are obtained after steaming and cooking, and processing the bamboo joints and the coarse fiber bundles by adopting a hot water counter-current washing method; S4, concentrating the obtained nature bamboo pulp fibers through a press filter, and performing high-concentration pulp grinding and low-concentration pulp grinding to obtain paper pulps; S5, performing dilution, sand removal, molding, dehydration, drying, wrinkling and rolling on the paper pulps to obtain raw paper; and S6, slicing and packaging the raw paper. The nature bamboo fiber kitchen towels with the high antibacterial property disclosed by the invention adopts a sulfur-free steaming and cooking process, an oxygen delignification step which is adopted generally in the industries is eliminated,and chloride-containing bleaching treatment is avoided, and therefore, a production process is green and environmentally friendly, the properties of bamboo raw materials are kept to the maximum extent, the nature bamboo fiber kitchen towels have a faint fragrance of bamboos, and bamboo quinone contained in the pulp has a more natural antibacterial effect.

Owner:四川环龙生活用品有限公司

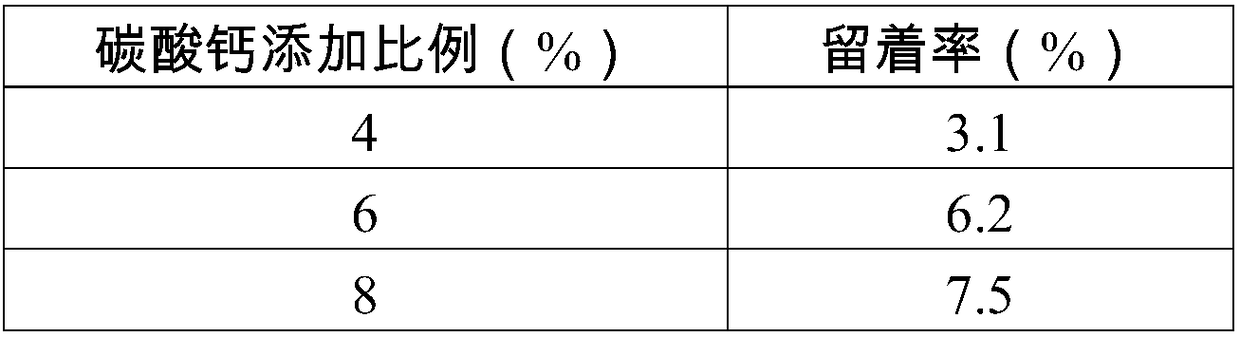

Method for increasing padding retention rate of paper process reconstituted tobacco product with diatomite

The invention discloses a method for increasing the padding retention rate of a paper process reconstituted tobacco product with diatomite. The method comprises the steps that (1) tobacco raw materials are extracted respectively by adding water; (2) solid-liquid separation of extracted materials is conducted respectively, solid phase sizing agents are made from solid phase materials through beating technology processing, all solid phase sizing agents are merged, diatomite padding is added, and finally reconstituted tobacco substrates are prepared through papermaking of a flow box; all aqueous phase materials are merged and prepared into coating liquid through impurity removal and concentration; (3) the reconstituted tobacco substrates are coated with the coating liquid, after drying in a drying box, flavoring in a drying cylinder and final slicing are conducted, reconstituted tobacco finished products are prepared. According to the method for increasing the padding retention rate of the paper process reconstituted tobacco product with diatomite, the retention rate of padding in reconstituted tobaccos is increased, and then physical performance, solution absorption performance and appearance performance of the reconstituted tobaccos are improved, and suction performance of substrates is improved.

Owner:CHINA TOBACCO ZHEJIANG IND

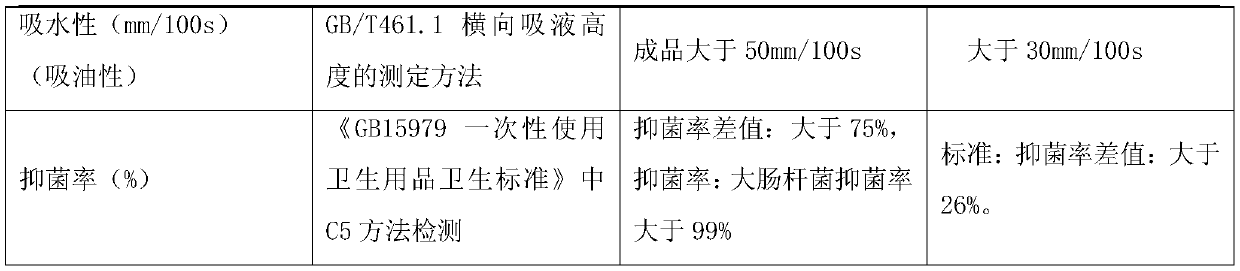

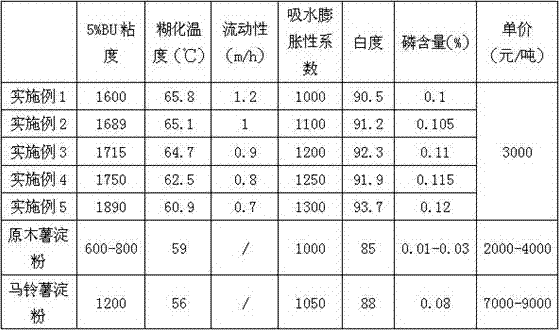

Modified starch prepared through cassava starch instead of potato starch and production technology thereof

The invention relates to the technical field of fine chemical engineering, in particular to modified starch prepared through cassava starch instead of potato starch and a production technology thereof. The production technology comprises the following steps that cassava starch and water are mixed and stirred to be uniform, the mass ratio of the cassava starch to the water is 1:1-1.2, diluted caustic soda is added to adjust the pH to be 10.8-11.0, and the temperature of 35-45 DEG C is kept constant; N-phosphoryl-N-methylimidazole, salicylo-phosphate and N-benzoyl ammonium phosphate are added to be subjected to a reaction for 4-6 h; the temperature is decreased to 35-36 DEG C, diluted acid is added to adjust the pH to be 10.2-10.5, and then a vinyl acetate monomer mixed solution is added to be subjected to a reaction for 1-3 h; sodium hydrogen sulfate and diluted acid are added to adjust the pH to be 5.6-5.8, rotational flow washing is performed, and dewatering and drying are performed to obtain the cassava modified starch. The production technology of the modified starch is simple and mature, the production cost is low, and the obtained cassava modified starch has the good water-retaining property, viscosity and ageing resistance.

Owner:东莞建泰生物科技有限公司

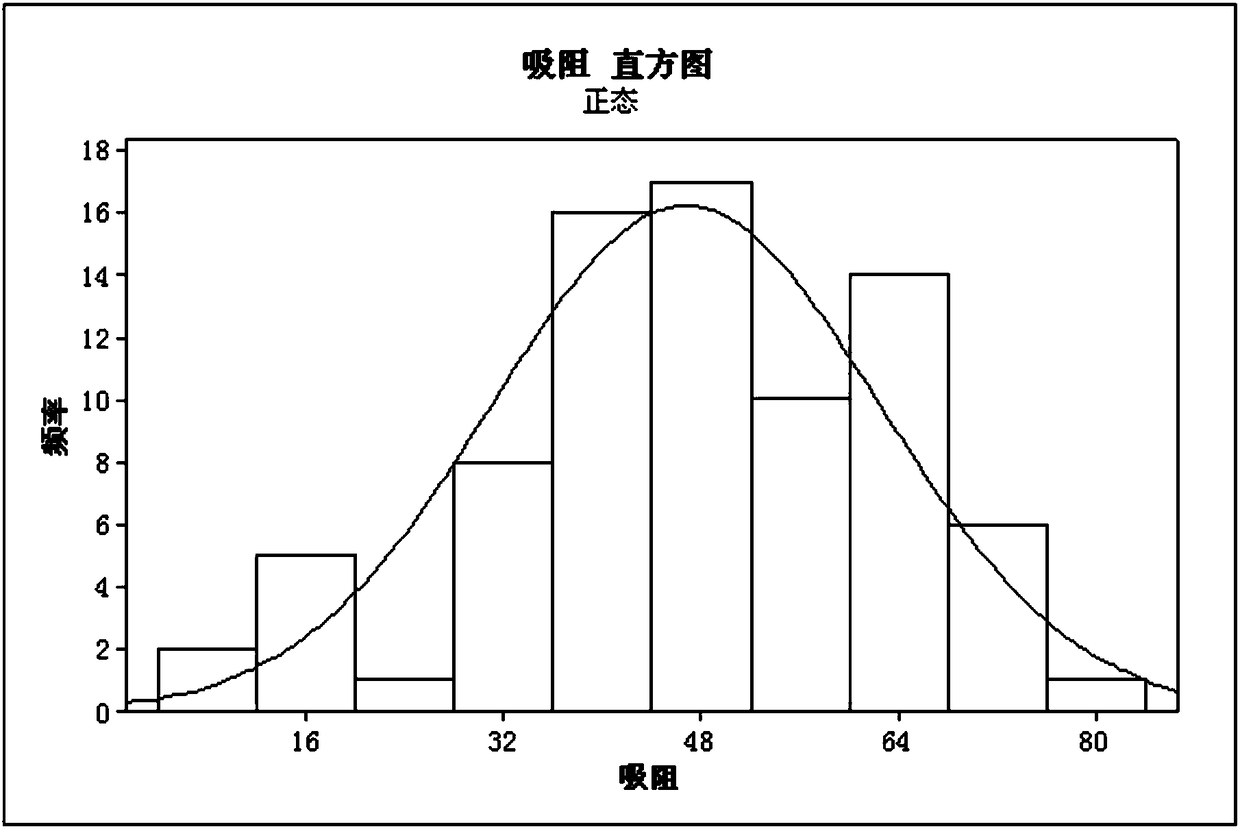

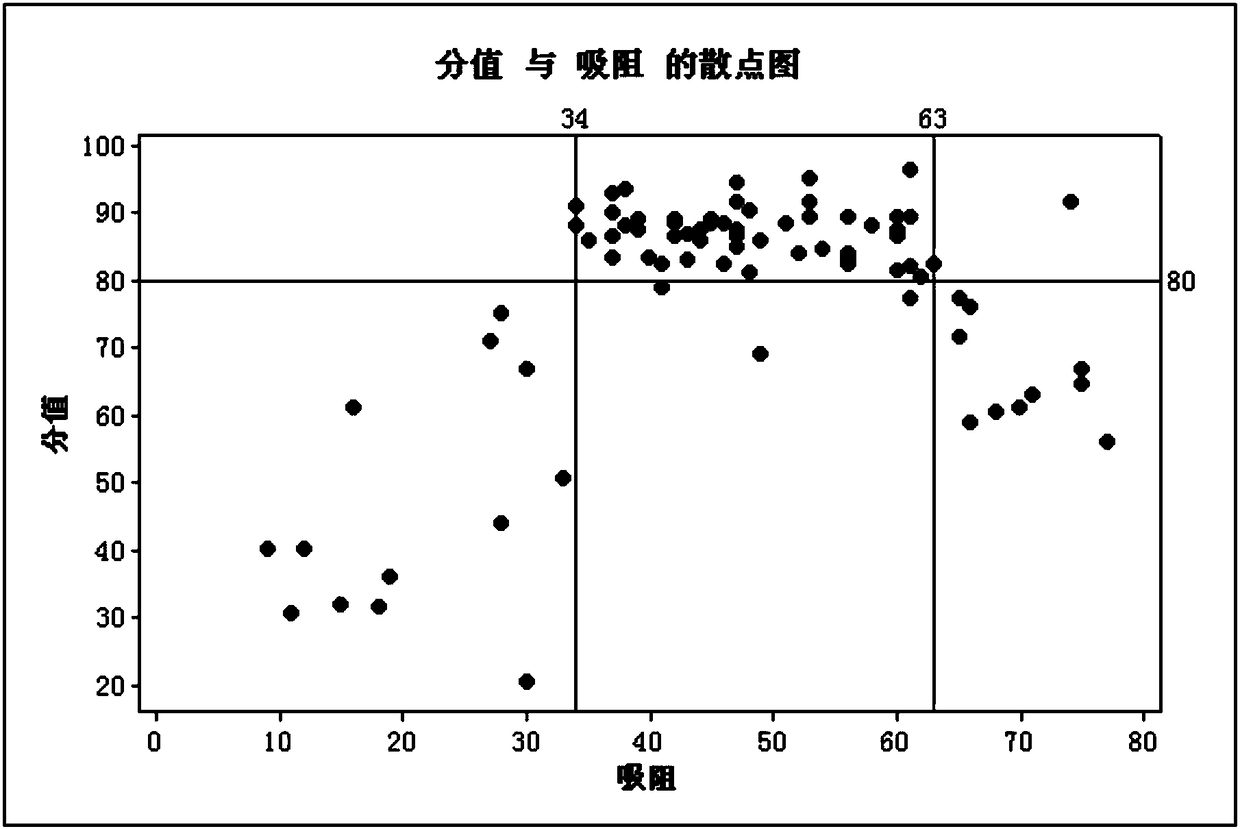

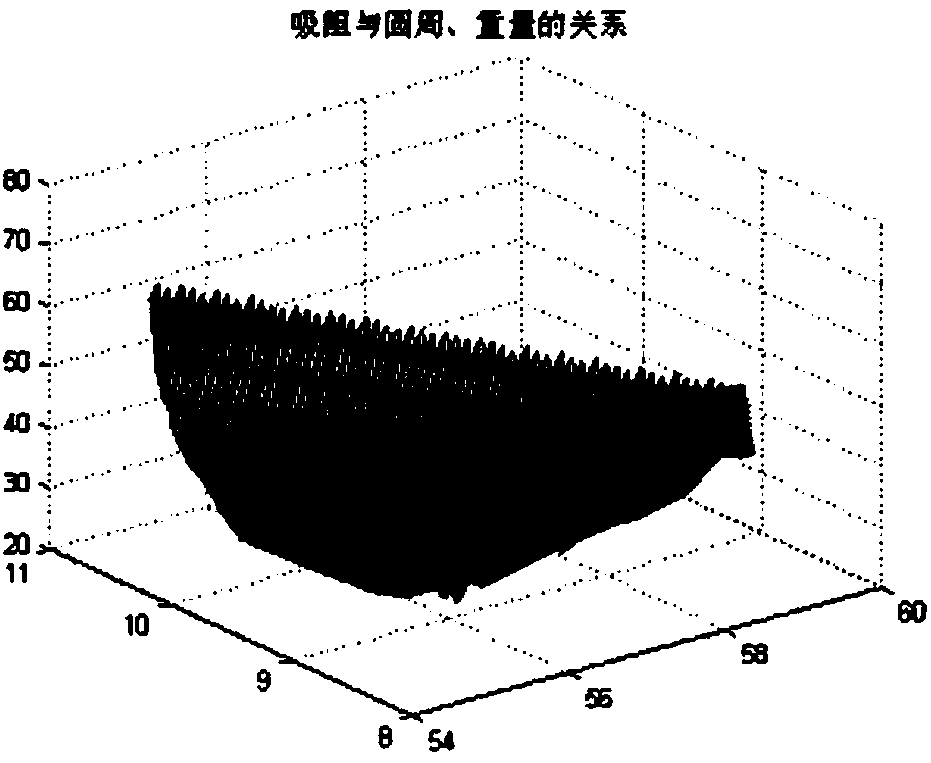

Suction resistance control method for manual whole-leaf-roll cigars

InactiveCN108056497AGood physical indexAccurate measurementMeasurement devicesTobacco pipesEngineeringSmoke

Owner:CHINA TOBACCO SHANDONG IND

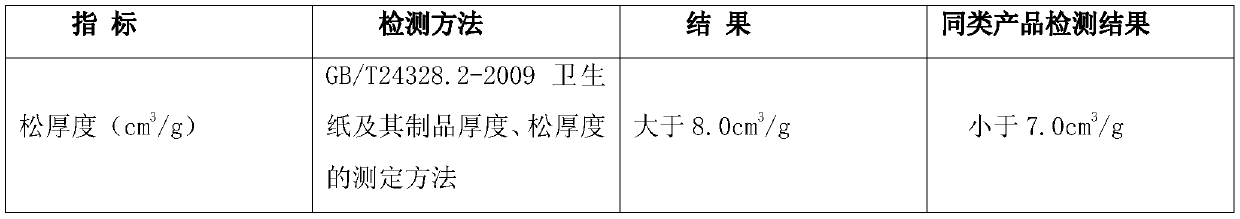

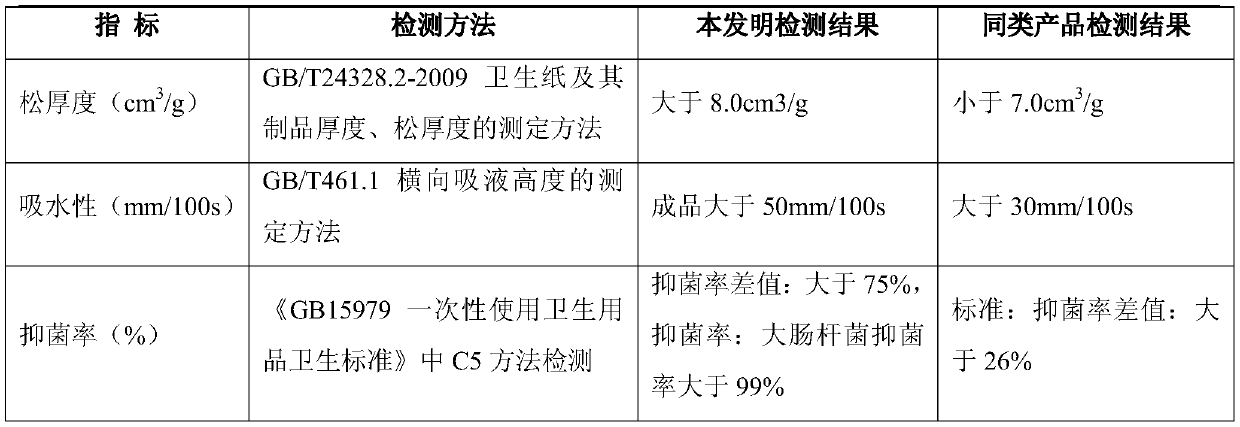

Highly bacteriostatic bamboo fiber toilet paper and preparation method

The invention discloses highly bacteriostatic bamboo fiber toilet paper and a preparation method. Natural color bamboo pulp is prepared by the steps of material preparation, stewing, screening, washing and the like of the highly bacteriostatic bamboo fiber toilet paper, the pulp is made into base paper by the processes of filter press concentration, high concentration grinding, low concentration grinding, low concentration desanding and the like, and then is post-processed, cut and packaged into finished products. According to the highly bacteriostatic bamboo fiber toilet paper, because a sulfur free stewing technology is adopted, an oxygen removal link commonly used in the industry is avoided, the bleaching treatment containing chlorine is not subjected, the production process is environmental friendly, the nature of the bamboo raw materials is retained to the greatest extent, the light bamboo fragrance is achieved, and bamboo quinine contained in the pulp also has the natural bacteriostatic effect.

Owner:四川环龙生活用品有限公司

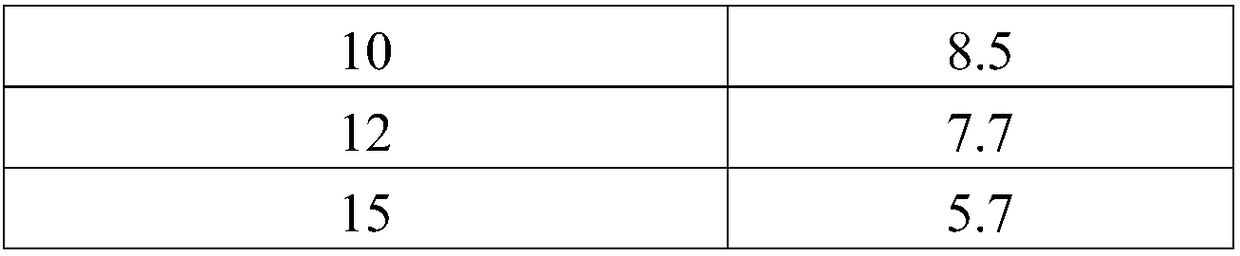

The method of improving the filler retention rate of reconstituted tobacco leaf products by using composite filler

The invention provides a method for improving the retention rate of a paper-making process reconstituted tobacco product filler by adopting a composite diatomite and calcium carbonate filler. The method comprises the steps that 1, water is added to tobacco raw materials for extraction; 2, the extracted raw materials are respectively subjected to solid-liquid separation, the solid-phase materials are treated into solid-phase slurries through a slurrying process, the solid-phase slurries are mixed, then the composite diatomite and calcium carbonate filler is added, and finally a reconstituted tobacco substrate is manufactured through paper making of a flow box, the water-phase materials are mixed and then are subjected to impurity removal and concentration to prepare coating liquid; 3, the coating liquid is coated to the reconstituted tobacco substrate, and a finished reconstituted tobacco product is obtained through drying in a drying box, perfuming of a drying cylinder and final slicing. By adopting the method, the retention rate of the filler in reconstituted tobaccos can be improved, further the physical property, liquid absorbing property, appearance property and the like of the reconstituted tobaccos are further improved, and the smoking quality of the substrate is improved.

Owner:CHINA TOBACCO ZHEJIANG IND

Method for improving filler retention rate of a papermaking-method reconstituted tobacco product by employing ternary composite filler

The invention provides a method for improving the filler retention rate of a papermaking-method reconstituted tobacco product by employing a ternary composite filler. The method comprises the steps of (1) adding water to tobacco raw materials for extraction separately; (2) carrying out solid-liquid separation on the extracted materials separately, treating solid-phase materials through a pulping technology to prepare solid-phase slurry, combining the solid-phase slurry, adding the ternary composite filler and carrying out papermaking through a headbox to prepare a reconstituted tobacco substrate, combining various water-phase materials and then carrying out purification and concentration to prepare a coating liquid; and (3) coating the reconstituted tobacco substrate with the coating liquid, drying with an oven, perfuming with a drying cylinder and finally slicing to prepare the reconstituted tobacco product. According to the method, the retention rate of the filler in the reconstituted tobacco product can be improved, so that the physical property, the liquid absorption performance, the appearance performance and the like of the reconstituted tobacco are improved and the smoking quality of the substrate is improved.

Owner:CHINA TOBACCO ZHEJIANG IND

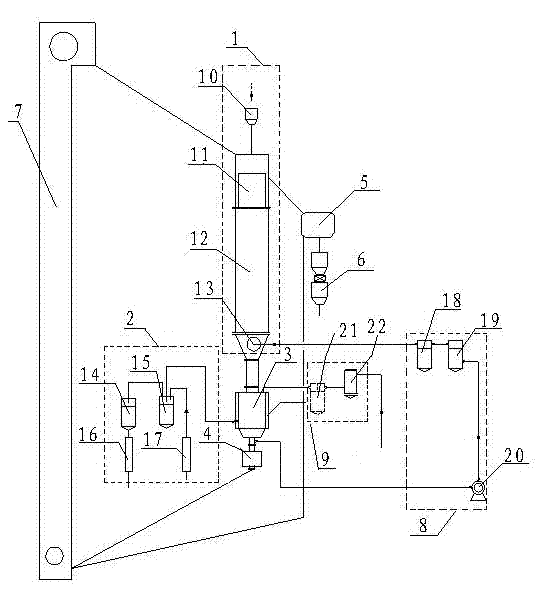

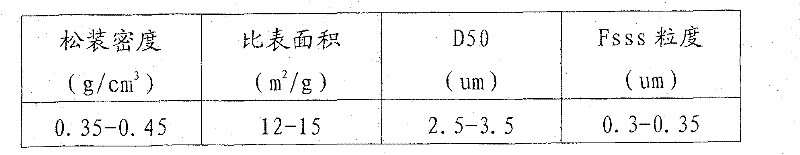

Equipment and method for preparing carbonyl nickel spheres

ActiveCN101985366BShort processReduce energy consumptionNickel carbonylsProcess engineeringMoving bed

The invention discloses equipment for preparing carbonyl nickel spheres. The equipment comprises a carbonyl grain feeding device (1), a carbon monoxide and carbonyl nickel gas mixture feeding device (2), a moving bed reactor (3), a feeding controller (4), a sieving machine (5), a storage tank (6), a hoisting machine (7), and a circulating device (8). The invention also discloses a method for using the equipment to prepare the carbonyl nickel spheres. The method is a preparation process, which comprises the following steps of: diluting carbonyl nickel steam with heated carbon monoxide gas; instantaneously decomposing the carbonyl nickel on the surfaces of carbonyl nickel grains in the moving bed reactor (3) filled with flowing hot carbonyl nickel grains; and rapidly reducing the surface energy of the carbonyl nickel spheres. By the equipment and the method, the carbonyl nickel spheres with the chemical purity not less than 99.5 percent can be obtained by controlling the technical conditions, and a technical foundation is laid for the large-scale technology production of carbonyl nickel spheres.

Owner:JINCHUAN GROUP LIMITED

A cashmere and apocynum woolen blended yarn

Owner:宁夏嘉源绒业集团有限公司

Heating compound fabric and production process thereof

InactiveCN101804706BHas heat-retaining propertiesWith moisture absorption and quick dryingLayered productsWoven fabricsPolyesterYarn

The invention relates to a heating compound fabric which is formed by compounding with a front-side fabric and a back-side fabric, and is characterized in that the front-side fabric is formed by weaving novel yarn with the granularity of 32s, 40s or 50s and polyester fibers with the granularity of 50-150D, the novel yarn comprises the following components in proportion: 65-75 percent of polyesterfiber and 25-35 percent of viscose fiber, and the front-side fabric is in the style of polar fleece; the back-side fabric is a polyester woven fabric of 100-250T; and the production process of the heating compound fabric comprises the following steps of: weaving the front-side fabric; dyeing; dewatering; slitting; drying; shaping; napping; polar fleecing into a polar fleece fabric; compounding with the back-side fabric; and obtaining a finished product. The invention provides the heating compound fabric which not only can heat but also can resist ultraviolet rays and the production process thereof.

Owner:JIANGSU DONGYUAN TEXTILE SCI & TECH IND

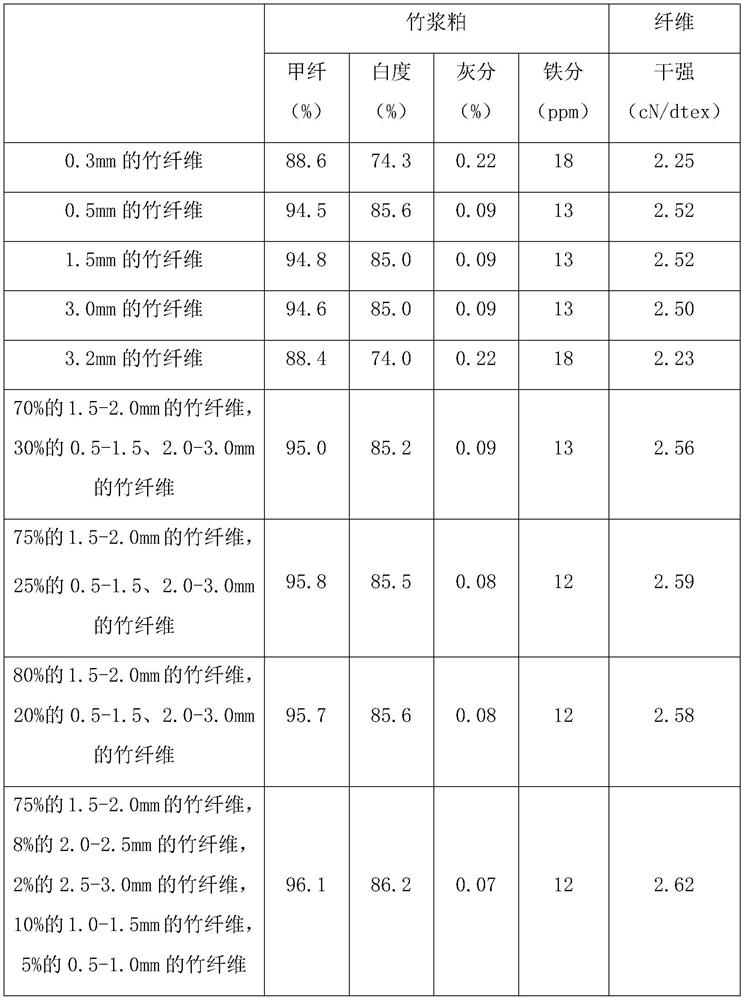

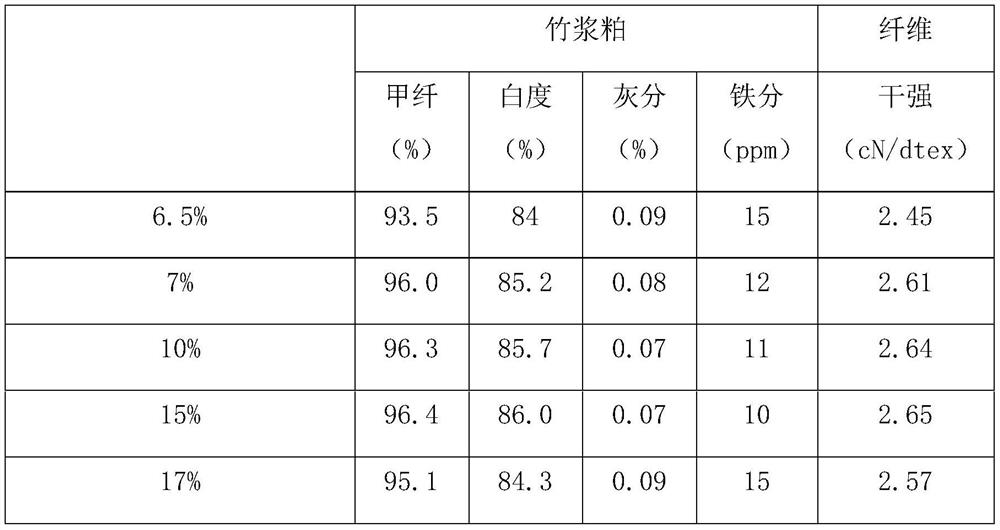

The preparation method of a bamboo pulp meal, bamboo pulp meal and fiber

ActiveCN112012034BGuaranteed length distribution ratioImprove qualityPulp bleachingPulping with inorganic basesCelluloseFiber

The invention discloses a preparation method of bamboo pulp, bamboo pulp and fiber, wherein the preparation method includes material preparation, material cutting, cooking and papermaking, and the preparation method also includes grading after the cooking and before the papermaking. , screened out 0.5-3.0mm bamboo fiber for papermaking. The invention ensures the cellulose length distribution ratio by increasing the grading process after cooking and before papermaking, so that the quality of the obtained bamboo pulp is higher, and the quality of the fibers obtained from the obtained bamboo pulp is better.

Owner:HEBEI JIGAO CHEM FIBER

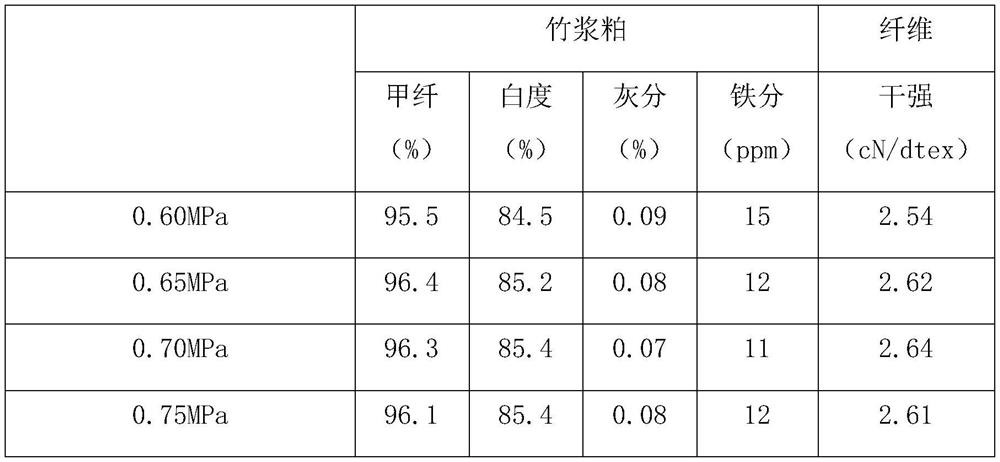

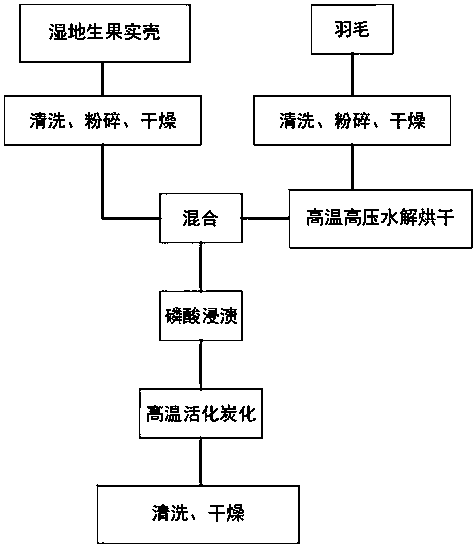

Method for preparing activated carbon from wetland raw fruit shell and hydrolyzed feather powder mixed base carbon precursor

ActiveCN108793157BSimple processSave energyCarbon compoundsOther chemical processesActivated carbonO-Phosphoric Acid

The invention provides a method for preparing activated carbon from a mixed base carbon precursor of wetland raw fruit shells and hydrolyzed feather meal. The method comprises the following steps: preparing a mixed base carbon precursor by taking wetland raw fruit shells and feather as raw materials; impregnating the mixed base carbon precursor into a phosphoric acid solution; performing high temperature carbonization on the impregnated mixed base carbon precursor; cleaning and drying the substance subjected to high temperature carbonization. The activated carbon disclosed by the invention takes the waste wetland raw fruit shells and feather as the raw materials, is capable of repeatedly utilizing waste resources, has excellent average specific surface area, average micro-porous specific surface area and average pore volume, and is excellent in adsorbing effect and particularly excellent in heavy metal adsorption capacity. Moreover, the preparation process disclosed by the invention issimple, short in production cycle and low in cost.

Owner:SHANDONG UNIV

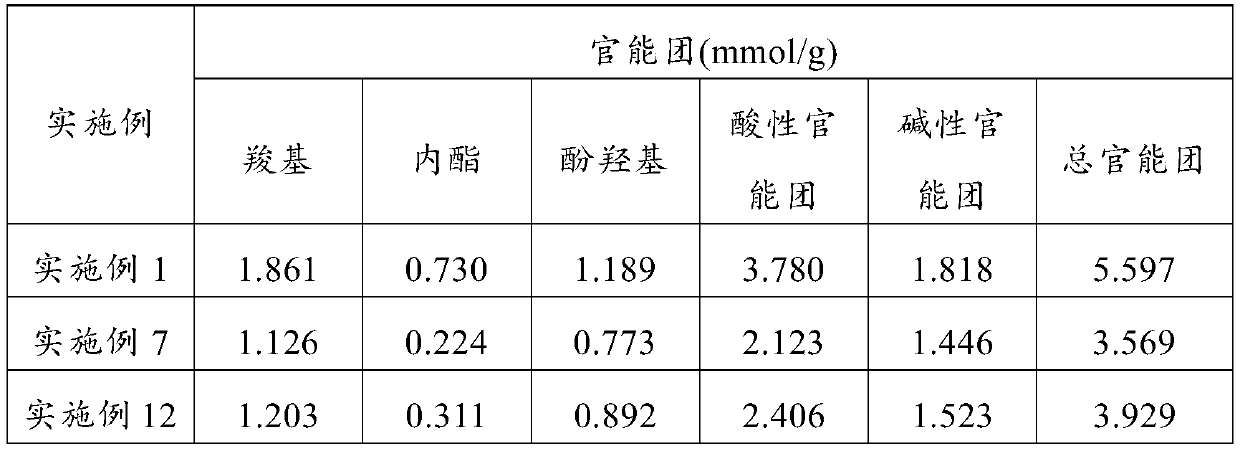

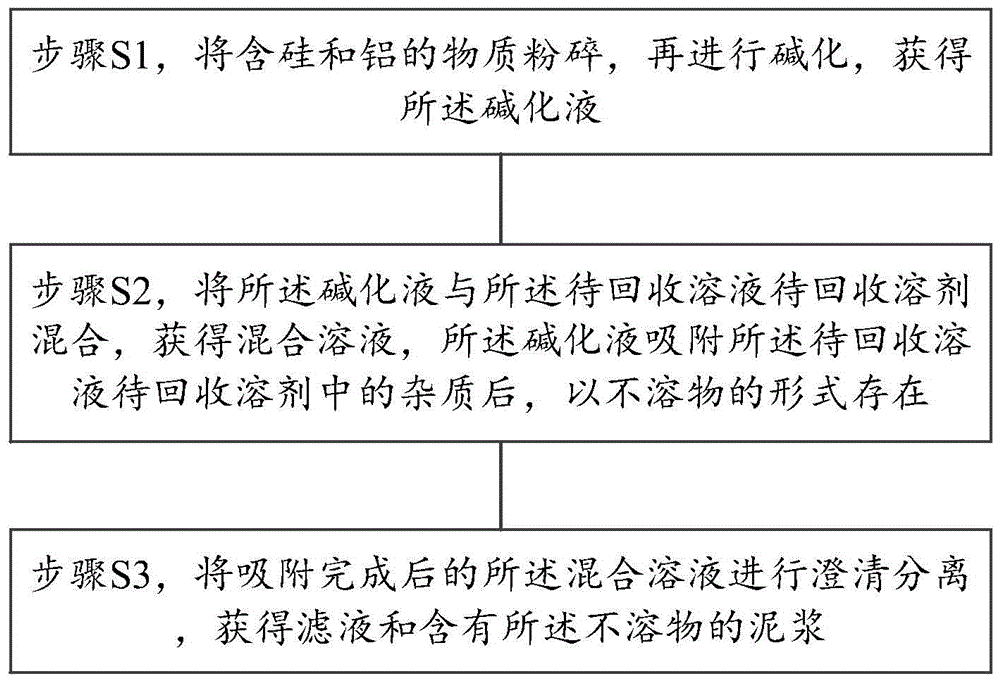

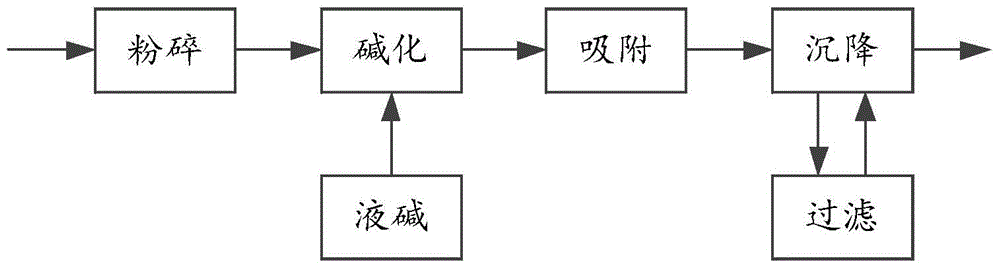

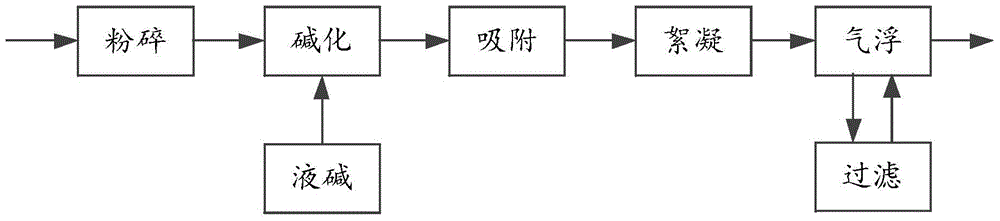

A kind of recovery method of solution for producing lyocell fiber

ActiveCN104761083BPossesses microporous adsorption propertiesGood lookingMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationColloidSlurry

Owner:CHINESE TEXTILE ACAD

A kind of polyether type polyurethane material and its preparation method and application

The invention provides a polyether urethane material. A method for preparing the polyether urethane material includes carrying out room-temperature reaction on polyhydric alcohol of initiators and alkylene oxide A in organic solvents under catalytic actions of alkali A for 1-30 h to obtain systems A; adding alkylene oxide B and metal sulfate into the systems A and carrying out room-temperature reaction on the alkylene oxide B, the metal sulfate and the systems A for 1-40 h to obtain systems B; adding alkylene oxide C and alkali B into the systems B, carrying out room-temperature reaction on the alkylene oxide C, the alkali B and the systems B for 1-60 h to obtain reaction mixtures and carrying out after-treatment on the reaction mixtures to obtain a finished product. The polyether urethane material and the method have the advantages that the polyether urethane material can be used for preparing polyurethane cellular elastomers which are used as shoe sole materials; the polyether urethane material is high in low-temperature performance, hydrolysis resistance and mildew resistance, the reaction time and the mold release time can be shortened when the polyether urethane material is used for preparing the polyurethane cellular elastomers, and the physical performance of the product can be improved.

Owner:薛立新

Low-wool-content multi-component chemical fiber blended fabric

ActiveCN103835048BImprove perceptionEasy to takeSucessive textile treatmentsWoven fabricsPolyesterPolymer science

The invention provides a low-wool-content multi-component chemical fiber blended fabric and a preparing method of the low-wool-content multi-component chemical fiber blended fabric and belongs to the field of spinning dyeing and finishing. Wool is added to multi-component chemical fibers and the low-wool-content multi-component chemical fiber blended fabric comprises, by weight, 30% to 40% of polyester staple fibers, 20% to 30% of modified polyester fibers, 10% to 20% of mucilage glue, 5% to 15% of Tencel, 8% to 30% of the wool and 0.1% to 0.6% of conductive fibers. The wool content of a traditional product is changed, wool fibers with the content smaller than 30% are blended with the polyester staple fibers, the modified polyester fibers, the mucilage glue, the Tencel and the conductive fibers in the chemical fibers in a combined mode, so that mutual advantage complement of the various fibers is achieved, and multiple colors, the high comfort degree and the easy-maintenance performance of the fabric are achieved with the low wool content. The technology is reasonable, the technical purpose of one bath dyeing of the wool and the multi-component chemical fibers is effectively achieved, and a new path is created for upgrading orientation and the comfort of chemical fiber fabric.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

Modified starch prepared by substituting tapioca starch for potato starch and its production process

The invention relates to the technical field of fine chemical engineering, in particular to modified starch prepared through cassava starch instead of potato starch and a production technology thereof. The production technology comprises the following steps that cassava starch and water are mixed and stirred to be uniform, the mass ratio of the cassava starch to the water is 1:1-1.2, diluted caustic soda is added to adjust the pH to be 10.8-11.0, and the temperature of 35-45 DEG C is kept constant; N-phosphoryl-N-methylimidazole, salicylo-phosphate and N-benzoyl ammonium phosphate are added to be subjected to a reaction for 4-6 h; the temperature is decreased to 35-36 DEG C, diluted acid is added to adjust the pH to be 10.2-10.5, and then a vinyl acetate monomer mixed solution is added to be subjected to a reaction for 1-3 h; sodium hydrogen sulfate and diluted acid are added to adjust the pH to be 5.6-5.8, rotational flow washing is performed, and dewatering and drying are performed to obtain the cassava modified starch. The production technology of the modified starch is simple and mature, the production cost is low, and the obtained cassava modified starch has the good water-retaining property, viscosity and ageing resistance.

Owner:东莞建泰生物科技有限公司

Intelligent health-preserving bed

InactiveCN103222753BImprove breathabilityGood warmth retentionStuffed mattressesSpring mattressesEngineeringBlanket

Provided is an intelligent health-preserving bed. A bed body rotates opposite to a rockshaft to form a revolving bed body and the revolving bed body conducts intelligent longitudinal rotation. A quilt supporting mechanism is installed at the upper portion of the revolving bed body, and therefore automatic covering and uncovering of a quilt can be achieved. A drinking cup balancing support is connected with a horizontal end face of the revolving bed body in a fastening mode, and therefore the intelligent health bed is convenient for people to drink. A thermostatic control module is arranged inside the revolving bed body and has the functions of temperature detection and adjustment, and therefore automatic constant temperature is achieved. A urine cup mechanism is arranged at the lateral portion inside the revolving bed body, therefore, the intelligent health cup is convenient for people to urinate, and automatic sealing of the urine cup mechanism is achieved. A playing device is arranged inside the revolving bed body, and therefore music playing is achieved and awakening ringing tones are provided. A bed body control part is a control core of the intelligent health bed and controls rotating of the revolving bed body, covering and uncovering of the quilt supporting mechanism, temperature adjusting of the thermostatic control module, and playing of the media player. The intelligent health-preserving bed is scientific in structure, comfortable in use and free to control.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

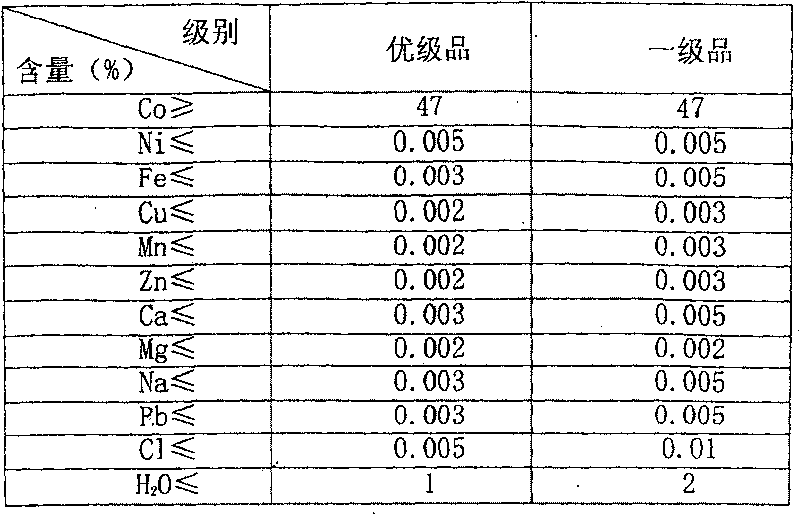

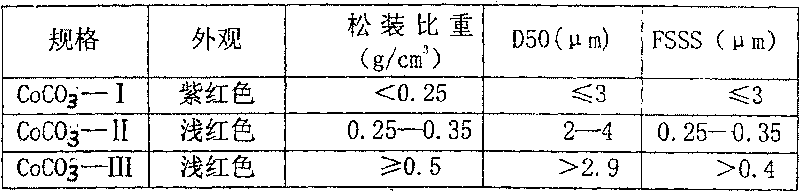

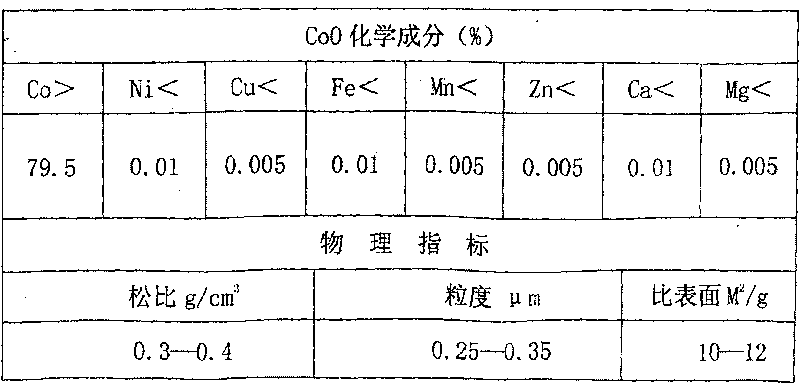

Method for producing cobaltous oxide

InactiveCN101200309BGood physical propertiesImprove qualityCobalt oxides/hydroxidesPower batteryHydrogen

The invention relates to a production method of CoO, firstly the CoCl solution and the carbon-ammonic precipitator are reacted in the reaction tank to generate CoCO3 slurry that is drained to the cobalt deposition tank, and then the slurry in the cobalt deposition tank is filtered, cleaned, dried and smashed to obtain the CoCO3, and then sintered in controlled atmosphere for production: the reduction furnace has seven computer temperature control zeros, before feeding, first protection gas is used to drive air in the furnace away, and then hydrogen is charged continuously, the material boat filled with CoCO3 passes through the seven computer temperature control zeros at a speed of 15minutes per time, so that the CoCO3 is decomposed to generate CoO in micro reduction atmosphere. As the CoCO3 produced in previous stage has good chemical indice and physical performance, plus computer multi-point low temperature control is adopted in the process of controlling atmosphere sintering, the CoOproduced in the invention has high content, high quality, and can be used as powder materials of high performance and large-power batteries, thereby making great contributions for prompting the development of novel energy industries.

Owner:周红阳

Method for Improving Filler Retention Rate of Papermaking Reconstituted Tobacco Leaf Products Using Titanium Dioxide

ActiveCN106901398BGood physical indexImprove the taste of smokingTobacco treatmentSlurryTobacco product

The invention provides a method for improving the filler retention rate of a papermaking-method reconstituted tobacco product by employing titanium dioxide. The method comprises the steps of (1) adding water to tobacco raw materials for extraction separately; (2) carrying out solid-liquid separation on the extracted materials separately, treating solid-phase materials through a pulping technology to prepare solid-phase slurry, combining the solid-phase slurry, adding a titanium dioxide filler and carrying out papermaking through a headbox to prepare a reconstituted tobacco substrate, combining various water-phase materials and then carrying out purification and concentration to prepare a coating liquid; and (3) coating the reconstituted tobacco substrate with the coating liquid, drying with an oven, perfuming with a drying cylinder and finally slicing to prepare the reconstituted tobacco product. According to the method, the retention rate of the filler in the reconstituted tobacco product can be improved, so that the physical property, the liquid absorption performance, the appearance performance and the like of the reconstituted tobacco are improved and the smoking quality of the substrate is improved.

Owner:CHINA TOBACCO ZHEJIANG IND

Method for Improving Filler Retention Rate of Reconstituted Tobacco Leaf Products Using Diatomite

The invention discloses a method for increasing the padding retention rate of a paper process reconstituted tobacco product with diatomite. The method comprises the steps that (1) tobacco raw materials are extracted respectively by adding water; (2) solid-liquid separation of extracted materials is conducted respectively, solid phase sizing agents are made from solid phase materials through beating technology processing, all solid phase sizing agents are merged, diatomite padding is added, and finally reconstituted tobacco substrates are prepared through papermaking of a flow box; all aqueous phase materials are merged and prepared into coating liquid through impurity removal and concentration; (3) the reconstituted tobacco substrates are coated with the coating liquid, after drying in a drying box, flavoring in a drying cylinder and final slicing are conducted, reconstituted tobacco finished products are prepared. According to the method for increasing the padding retention rate of the paper process reconstituted tobacco product with diatomite, the retention rate of padding in reconstituted tobaccos is increased, and then physical performance, solution absorption performance and appearance performance of the reconstituted tobaccos are improved, and suction performance of substrates is improved.

Owner:CHINA TOBACCO ZHEJIANG IND

A method for improving the filler retention rate of reconstituted tobacco leaf products by papermaking

The invention provides a method for improving the retention rate of paper-making process reconstituted tobacco product filler by adopting diatomite and titanium dioxide composite filler. The method comprises the steps that 1, water is added to extract tobacco raw material; 2, the extracted material is subjected to solid-liquid separation respectively, the solid-phase materials are treated by adopting a pulping process to obtain solid-phase slurry, the solid-phase slurry is mixed, the composite filler is added, finally a reconstituted tobacco substrate is manufactured through papermaking of a flow box, and water-phase materials are mixed and then are subjected to impurity removal and concentration to prepare a coating solution; 3, the coating solution is coated to the reconstituted tobacco substrate, and a finished reconstituted tobacco product is obtained through drying of a drying oven, flavoring of a drying cylinder and final slicing. By adopting the method, the retention rate of the filler in reconstituted tobaccos can be improved, the physical properties, solution absorption performance, appearance performance and the like of the reconstituted tobaccos are further improved, and the smoking quality of the substrate is improved.

Owner:CHINA TOBACCO ZHEJIANG IND

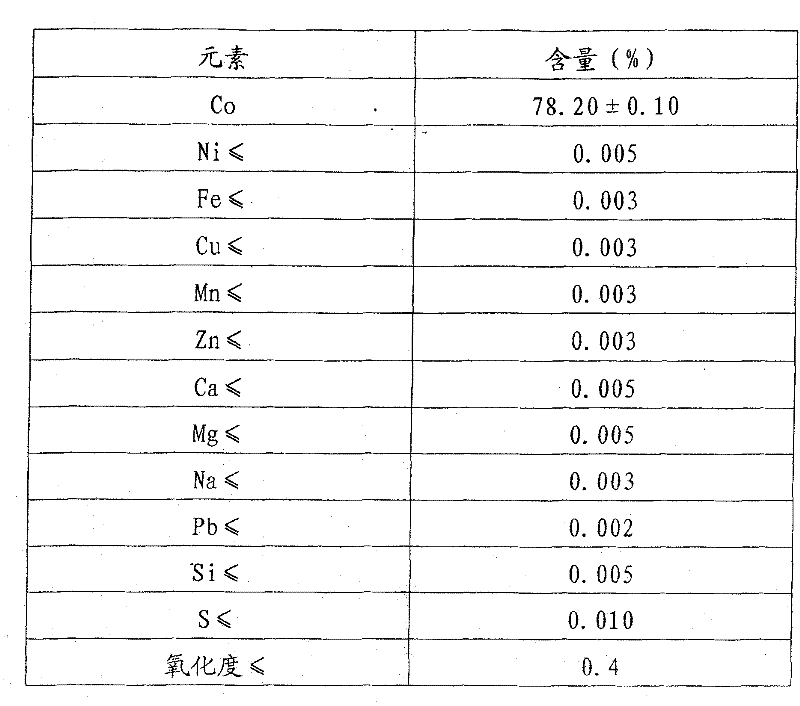

Production method of cobaltous oxide for power battery

ActiveCN101786672BImprove energy storage utilizationExtended service lifeProductsElectrode manufacturing processesPositive pressureSlurry

The invention relates to a production method of cobaltous oxide for a power battery, comprising the following steps of: firstly reacting a cobalt chloride solution with an ammonium acid carbonate precipitant through a third-order reaction tank to generate basic cobaltous carbonate slurries; then filtering the slurries, slurrying, washing, drying, and protecting and crashing by an inert gas to obtain basic cobaltous carbonate powder; then decomposing through a positive pressure atmosphere, wherein a decomposing furnace is internally provided with 10 computer temperature control areas, air inside the decomposing furnace is driven by the inert gas before feeding, then a CO2 gas is continuously charged, and a material boat loaded with the basic cobaltous carbonate powder passes through the 10computer temperature control areas at the speed of 5 minutes per time so that basic cobaltous carbonate is decomposed to generate the cobaltous oxide for the power battery in the positive pressure atmosphere. The invention saves the energy and has low production cost; in addition, the cobaltous oxide has great high chemical purity and physical performance and can be used as powder materials of the power high-performance and high-power battery.

Owner:周红阳

Method for improving retention rate of paper-making process reconstituted tobacco product filler by adopting diatomite and titanium dioxide composite filler

The invention provides a method for improving the retention rate of paper-making process reconstituted tobacco product filler by adopting diatomite and titanium dioxide composite filler. The method comprises the steps that 1, water is added to extract tobacco raw material; 2, the extracted material is subjected to solid-liquid separation respectively, the solid-phase materials are treated by adopting a pulping process to obtain solid-phase slurry, the solid-phase slurry is mixed, the composite filler is added, finally a reconstituted tobacco substrate is manufactured through papermaking of a flow box, and water-phase materials are mixed and then are subjected to impurity removal and concentration to prepare a coating solution; 3, the coating solution is coated to the reconstituted tobacco substrate, and a finished reconstituted tobacco product is obtained through drying of a drying oven, flavoring of a drying cylinder and final slicing. By adopting the method, the retention rate of the filler in reconstituted tobaccos can be improved, the physical properties, solution absorption performance, appearance performance and the like of the reconstituted tobaccos are further improved, and the smoking quality of the substrate is improved.

Owner:CHINA TOBACCO ZHEJIANG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com