Polyether urethane material, method for preparing same and application of polyether urethane material

A technology of polyether polyurethane and reaction mixture, which is applied in the field of polyether polyurethane material and its preparation, can solve problems such as cracking and breaking of shoe soles, achieve shortened reaction time and demoulding time, good toughness, strong low temperature performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of polyether polyurethane material:

[0040] In the reaction flask, add 1,2-propanediol (7.61g, 0.1mol), propylene oxide (5.81g, 0.1mol), sodium hydroxide (4g, 0.1mol), methanol (5mL), and react at room temperature for 12h; Then add propylene oxide (5.81g, 0.1mol), magnesium aluminum sulfate (75g, 0.1mol), react at room temperature for 20h; then add ethylene oxide (8.81g, 0.2mol), sodium hydroxide (4g, 0.1mol ), react at room temperature for 24h, then wash the reaction mixture with 10mL ethanol-water mixed solution with a volume ratio of 1:1, centrifuge at 5000r / min to remove the supernatant, repeat the above washing and centrifugation process for 3 times, and finally dry to obtain the Polyether polyurethane material 10g.

[0041] Preparation of polyurethane microcellular elastomer:

[0042] (1) Add 60 g of diphenylmethane diisocyanate and 15 g of liquefied diphenylmethane diisocyanate into a four-neck flask, keep the temperature at 70°C, and then add 5 g ...

Embodiment 2

[0048] Preparation of polyether polyurethane material:

[0049] In the reaction flask, add 1,2-propanediol (7.61g, 0.1mol), propylene oxide (8.71g, 0.15mol), sodium hydroxide (4g, 0.1mol), methanol (5mL), and react at room temperature for 12h; Then add propylene oxide (5.81g, 0.1mol), magnesium aluminum sulfate (75g, 0.1mol), react at room temperature for 20h; then add ethylene oxide (6.61g, 0.15mol), sodium hydroxide (4g, 0.1mol ), react at room temperature for 24h, then wash the reaction mixture with 10mL ethanol-water mixed solution with a volume ratio of 1:1, centrifuge at 5000r / min to remove the supernatant, repeat the above washing and centrifugation process for 3 times, and finally dry to obtain the Polyether polyurethane material 15g.

[0050] Preparation of polyurethane microcellular elastomer:

[0051] (1) Add 70 g of diphenylmethane diisocyanate and 20 g of liquefied diphenylmethane diisocyanate into a four-neck flask, keep the temperature at 70°C, and then add 5 ...

Embodiment 3

[0057] Preparation of polyether polyurethane material:

[0058] In the reaction flask, add 1,2-propanediol (11.41g, 0.15mol), propylene oxide (5.81g, 0.1mol), sodium hydroxide (4g, 0.1mol), methanol (10mL), and react at room temperature for 12h; Then add propylene oxide (4.41g, 0.1mol), magnesium aluminum sulfate (75g, 0.1mol), react at room temperature for 20h; then add ethylene oxide (6.61g, 0.15mol), sodium hydroxide (4g, 0.1mol ), react at room temperature for 24h, then wash the reaction mixture with 10mL ethanol-water mixed solution with a volume ratio of 1:1, centrifuge at 5000r / min to remove the supernatant, repeat the above washing and centrifugation process for 3 times, and finally dry to obtain the Polyether polyurethane material 15g.

[0059] Preparation of polyurethane microcellular elastomer:

[0060] (1) Add 80 g of diphenylmethane diisocyanate and 30 g of liquefied diphenylmethane diisocyanate into a four-necked flask, keep the temperature at 80°C, and then ad...

PUM

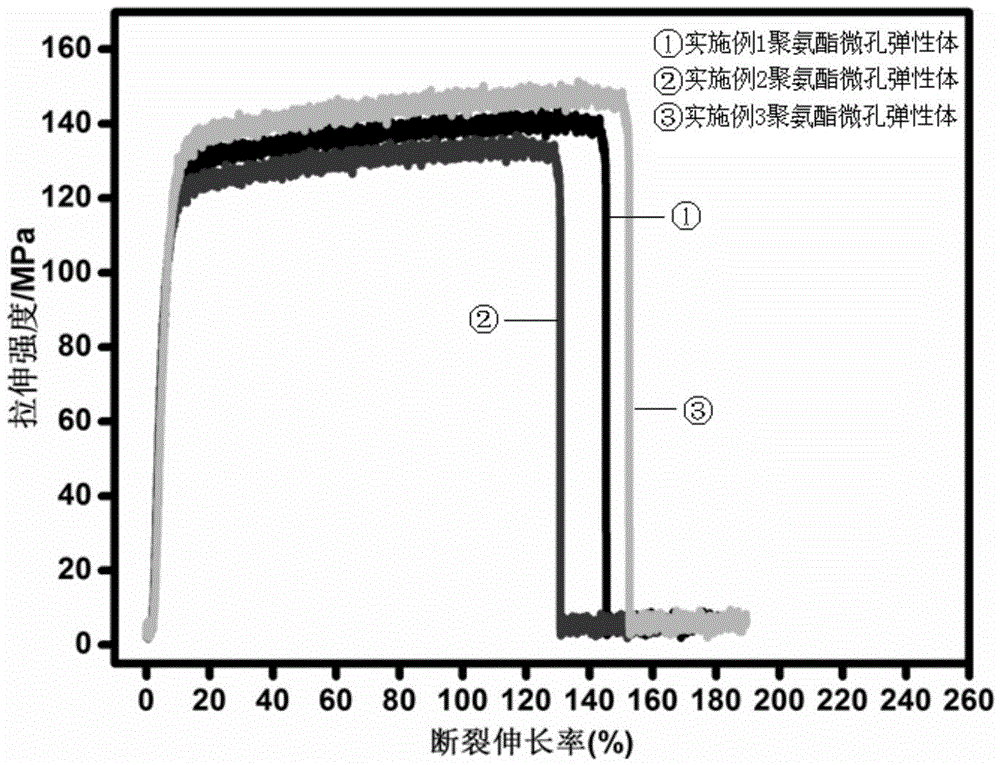

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com