Cover plate of supercapacitor

A technology of supercapacitor and cover plate, applied in the direction of hybrid box/housing/package, etc., can solve the problems of aggravated battery damage, disaster, failure, etc., and achieve the effect of life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

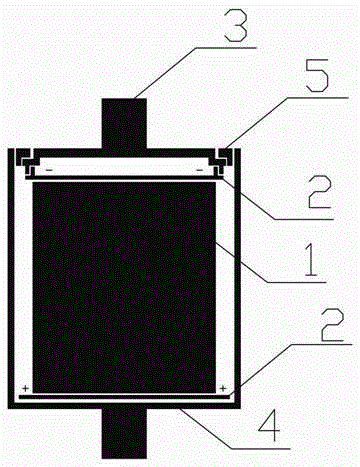

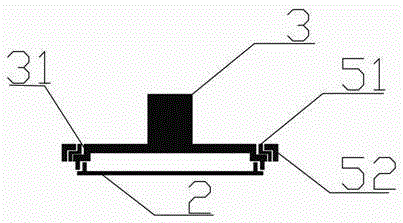

[0021] Such as Figure 1-2 As shown, a cover plate of a supercapacitor includes a cell 1, positive and negative current collectors 2, an upper aluminum cover 3, an aluminum shell 4 and a ceramic insulating ring 5, and is characterized in that: the cell 1 is placed In the interior of the aluminum shell 4, positive and negative current collectors 2 are provided on the upper and lower sides of the battery cell 1, and the aluminum shell 4 is provided with an upper aluminum cover 3 on the top, and a groove 31 is provided on the edge of the aluminum cover 3, and the groove 31 and the The contact of the aluminum shell 4 is provided with a ceramic insulating ring 5, the ceramic insulating ring 5 is composed of an inner ceramic ring 51 and an outer aluminum ring 52, the inner ceramic ring 51 matches the shape of the groove 31, and the outer aluminum ring 52 fills The gap between the flat inner ceramic ring 51 and the aluminum cover 3, the upper aluminum cover 3, the outer aluminum ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com