Modified asphaltum material and preparation process thereof

A technology for modifying asphalt and asphalt raw materials, which is applied to building insulation materials, building components, buildings, etc., to achieve the effects of superior elastic recovery performance, good high-temperature performance, and strong low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

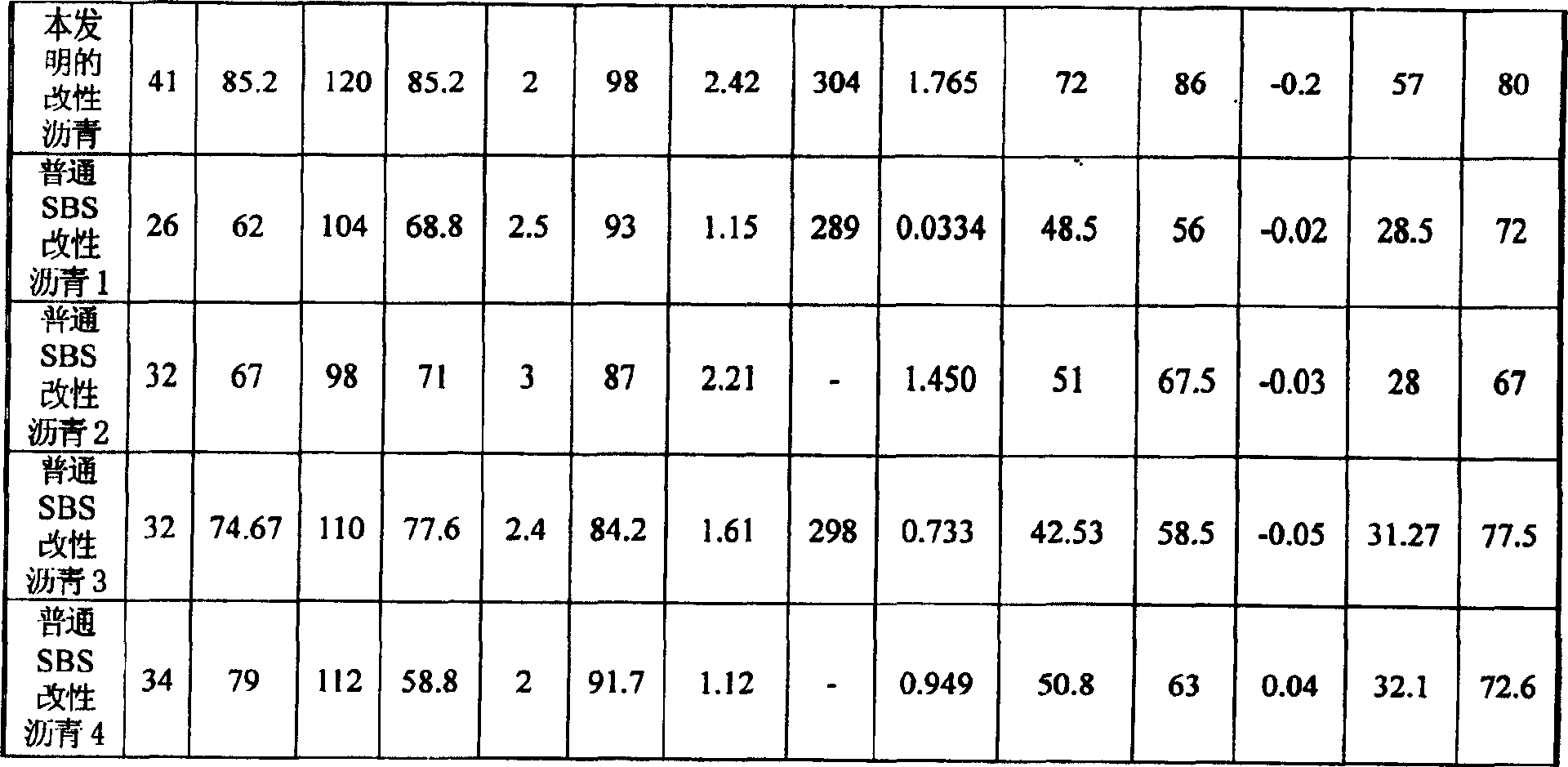

[0023] The mass percentage is: 70% of petroleum pitch, 5% of styrene-isoprene-styrene SIS and 5% of butadiene SB, 3% of crystalline sulfur, 17% of catalytic cracking oil mixed at 150 ° C , high-speed shearing, shearing speed 10000 RPM, time 90min. A modified bitumen with a polymer network structure is obtained.

Embodiment 2

[0025] The mass percentage is: 80% petroleum pitch, 5% styrene-isoprene-styrene SIS and 5% butadiene-styrene block SBR, 5% sulfur powder, 5% solvent The extracted refined oil was mixed at 160°C with high-speed shearing at a shear rate of 15,000 RPM for 60 minutes. A modified bitumen with a polymer network structure is obtained.

Embodiment 3

[0027] The mass percentage is: 85% petroleum pitch, 3% butadiene-styrene block SBR and 4% butadiene SB, 7.5% tall oil, 0.5% inorganic metal oxide at 180 ° C Mixing, high-speed shearing, shearing speed 10000 RPM, time 45min. A modified bitumen with a polymer network structure is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com