Method for producing cobaltous oxide

A technology of cobaltous oxide and production method, applied in cobalt oxide/cobalt hydroxide and other directions, can solve the problems of large temperature difference, poor product consistency, large color difference, etc.

Inactive Publication Date: 2010-06-09

周红阳

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Using traditional reduction furnace equipment, that is, digital display temperature control, so the temperature of each zone in the furnace varies greatly, the product consistency is poor, and the color difference is large

It is difficult for the product to meet the requirements of high-performance and high-power batteries in terms of physical indicators, chemical composition and electrochemical performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0028] The production steps are the same as above, and will not be repeated here. The protective gas used in this example is nitrogen.

Embodiment 2

[0030] Same as Example 2, except that the shielding gas is helium.

Embodiment 3

[0032] Same as Example 1, the difference is that the protective gas is neon.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

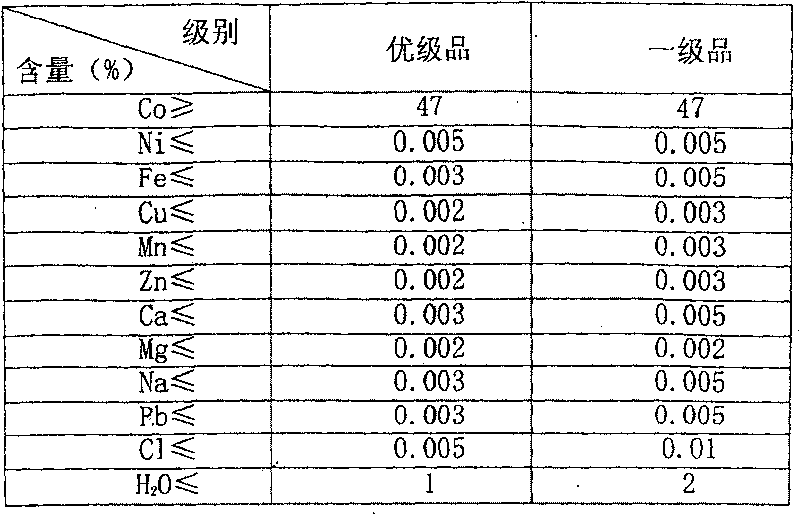

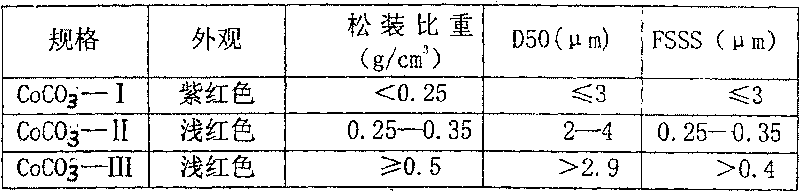

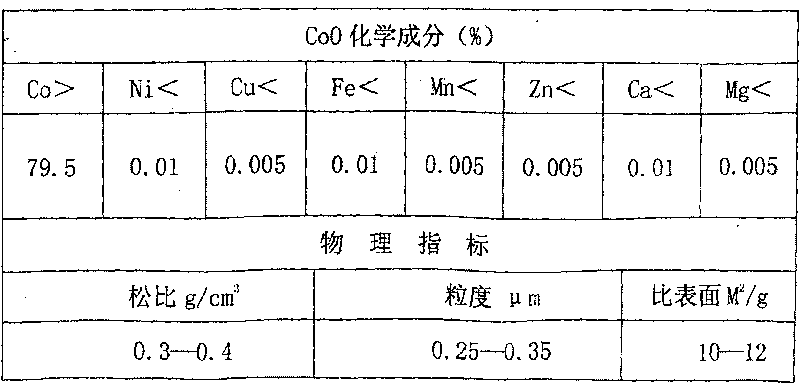

The invention relates to a production method of CoO, firstly the CoCl solution and the carbon-ammonic precipitator are reacted in the reaction tank to generate CoCO3 slurry that is drained to the cobalt deposition tank, and then the slurry in the cobalt deposition tank is filtered, cleaned, dried and smashed to obtain the CoCO3, and then sintered in controlled atmosphere for production: the reduction furnace has seven computer temperature control zeros, before feeding, first protection gas is used to drive air in the furnace away, and then hydrogen is charged continuously, the material boat filled with CoCO3 passes through the seven computer temperature control zeros at a speed of 15minutes per time, so that the CoCO3 is decomposed to generate CoO in micro reduction atmosphere. As the CoCO3 produced in previous stage has good chemical indice and physical performance, plus computer multi-point low temperature control is adopted in the process of controlling atmosphere sintering, the CoOproduced in the invention has high content, high quality, and can be used as powder materials of high performance and large-power batteries, thereby making great contributions for prompting the development of novel energy industries.

Description

technical field [0001] The invention relates to a method for producing powder materials used in the battery industry, in particular to a method for producing cobaltous oxide powder with high cobalt content. Background technique [0002] At present, the battery-grade common cobaltous oxide products produced by domestic manufacturers are produced by calcination and decomposition technology. Using traditional reduction furnace equipment, that is, using digital display temperature control, so the temperature of each zone in the furnace varies greatly, and the product produced has poor consistency and large color difference. It is difficult for products to meet the requirements of high-performance and high-power batteries in terms of physical indicators, chemical composition and electrochemical performance. [0003] At present, the battery industry and scientists around the world are conducting extensive and in-depth industrial development research on how to improve the specific...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01G51/04

Inventor 周红阳张春金

Owner 周红阳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com