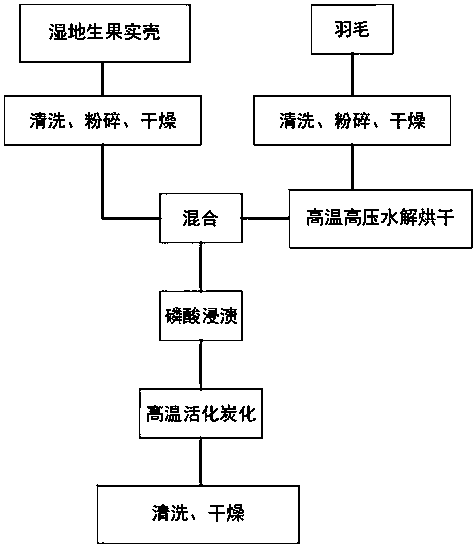

Method for preparing activated carbon from wetland raw fruit shell and hydrolyzed feather powder mixed base carbon precursor

A technology for hydrolyzing feather meal and feathers, which is applied in chemical instruments and methods, carbon compounds, and other chemical processes, etc., can solve the problems of increased terminal treatment cost, high price, and environmental pollution of cleaning waste liquid, and achieves heavy metal adsorption capacity. Good, short production cycle, the effect of protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

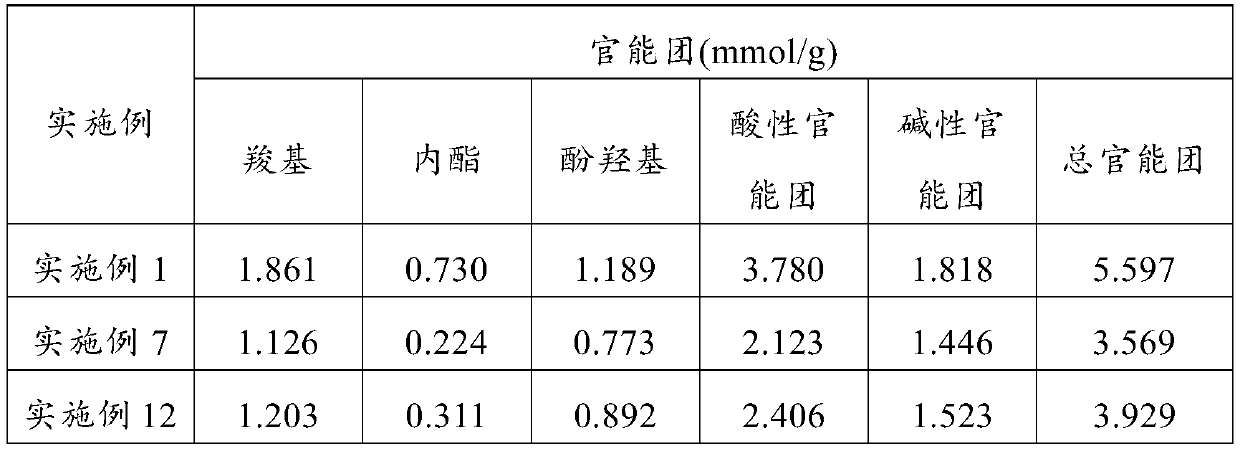

Embodiment 1

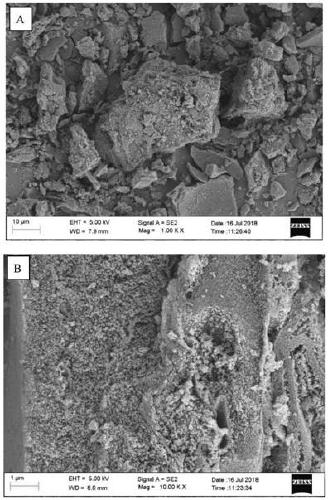

[0046]Wash the water chestnut skin and feathers several times with water to remove the attached impurities, dry them at 105°C for 6 hours, and then crush them with a pulverizer. The particle size of the crushed water chestnut skins is 0.45-1.0mm, and the fiber length of feather powder is figure 2 Shown in A), the average specific surface area (BET) of activated carbon is 1461.68m 2 / g, average micropore specific surface area 752.20m 2 / g, average pore volume 0.637cm 3 / g.

[0047] Use the activated carbon to test the adsorption of Ni(II) and Cd(II). Take 50ml of Ni(II) and Cd(II) solution with a concentration of 40mg / L in a 150ml Erlenmeyer flask, and add 0.04g of activated carbon. Shake at a frequency of 200rpm for 48 hours in a constant temperature air bath shaker, and after equilibrium, filter with a 0.45um filter membrane, take the filtrate, measure the concentration of remaining Ni(II) and Cd(II) in the filtrate, and calculate the adsorption capacity. Results The adsor...

Embodiment 2

[0049] Wash the water chestnut skin and feathers several times with water to remove the attached impurities, dry them at 105°C for 6 hours, and then crush them with a pulverizer. The particle size of the crushed water chestnut skins is 0.45-1.0mm, and the fiber length of feather powder is 2 / g, average micropore specific surface area 738.10m 2 / g, average pore volume 0.636cm 3 / g.

[0050] Use this gac to test the adsorption of its Ni(II) and Cd(II), the test method is the same as in Example 1, the result is that the gac is 27.46mg / g to the adsorption of Ni(II), and the adsorption to Cd(II) It is 28.24mg / g.

Embodiment 3

[0052] Wash the water chestnut skin and feathers several times with water to remove the attached impurities, dry them at 105°C for 6 hours, and then crush them with a pulverizer. The particle size of the crushed water chestnut skins is 0.45-1.0mm, and the fiber length of feather powder is 2 / g, average micropore specific surface area 731.08m 2 / g, average pore volume 0.632cm 3 / g.

[0053] Use this activated carbon to test the adsorption of Ni(II) and Cd(II), the test method is the same as in Example 1, the result is that the activated carbon has an adsorption capacity of 25.12mg / g for Ni(II), and the adsorption capacity for Cd(II) It is 27.74 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com