Equipment and method for preparing carbonyl nickel spheres

A technology of nickel carbonyl balls and nickel carbonyl, which is applied in the direction of nickel carbonyl, can solve the problems of difficult continuous production, affecting product quality, and unsustainable material balance, and achieves the effects of short process, automatic control, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

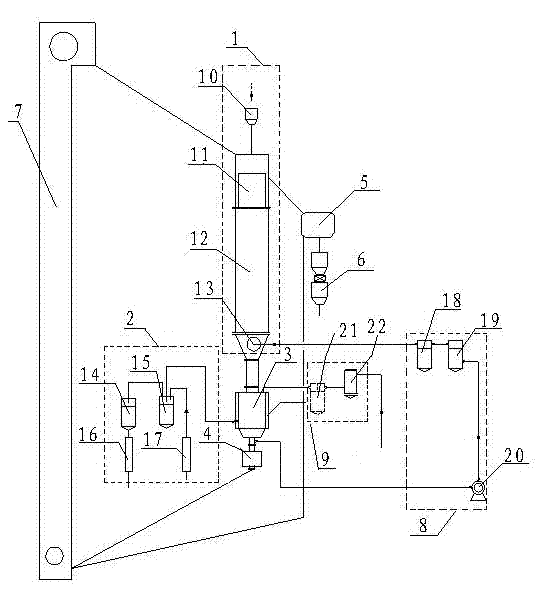

[0035] see figure 1 To illustrate the equipment for preparing nickel carbonyl balls of the present invention. The equipment includes a nickel carbonyl grain feeding device 1, a carbon monoxide and nickel carbonyl mixed gas feeding device 2, a moving bed reactor 3, a material controller 4, a screening machine 5, a storage tank 6, an elevator 7 and a circulation device 8. Wherein, the outlet of the nickel carbonyl grain feeding device 1 is connected to the top inlet of the moving bed reactor 3, the inlet of the feeding device 1 is connected to the top outlet of the elevator 7, and the inlet of the feeding device 1 is also connected to the inlet of the screening machine 7 . The carbon monoxide and nickel carbonyl mixed gas feeding device 2 is connected to the lower inlet of the moving bed reactor 3; the material controller 4 is installed below the moving bed reactor 3, and its outlet is connected to the bottom inlet of the elevator 7; the circulation device 8 will feed The bott...

Embodiment 1

[0058] The temperature of the circulating nickel grains is heated to 300°C, and the pumping capacity of the circulating fan is 80Nm 3 / h, the flow rate of grains is 250kg / min, and the flow rate of nickel carbonyl entering the mixing tank is 1Nm 3 / h, CO flow rate is 200Nm 3 / h, the pressure in the reactor is maintained at 100Kpa, and the temperature of the reactor is 150°C, it takes 120 days for the grain to grow from about 10μm to 10mm, and the purity of the nickel ball reaches more than 99.99%, and the impurity cobalt is not high 0.0005%, lead not higher than 0.0001%, copper not higher than 0.001%, zinc not higher than 0.0005%.

Embodiment 2

[0060] The temperature of the circulating nickel grains is heated to 150°C, and the pumping capacity of the circulating fan is 50Nm 3 / h, the flow rate of the crystal grains is 150kg / min, and the flow rate of nickel carbonyl entering the mixing tank is 1Nm 3 / h, CO flow rate is 200Nm 3 / h, the pressure in the reactor is maintained at 100Kpa, and the temperature of the reactor is 150°C, it takes 135 days for the grain to grow from about 10μm to 10mm, and the purity of the nickel ball reaches more than 99.99%, and the impurity cobalt is not high 0.0005%, lead not higher than 0.0001%, copper not higher than 0.001%, zinc not higher than 0.0005%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com