Modified starch prepared by substituting tapioca starch for potato starch and its production process

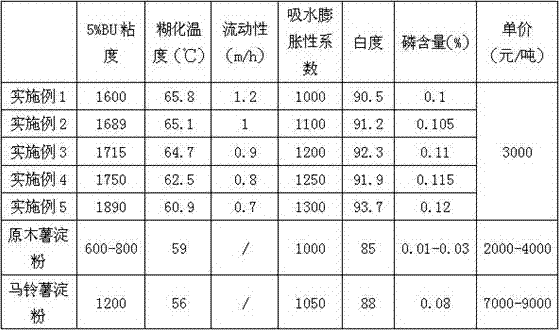

A technology for cassava modified starch and potato starch, which is applied in the field of fine chemicals, can solve the problems that the water retention, viscosity and anti-aging properties of potato starch cannot be achieved, the processing cost of the papermaking industry is increased, and the price of potato starch is high. Good aging performance and strong water retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The modified starch prepared by substituting tapioca starch for potato starch comprises the following raw materials in parts by weight:

[0051] Tapioca starch 100 parts

[0052] N-phosphoryl-N-methylimidazole 0.5 parts

[0053] Salicyl Phosphate 0.5 parts

[0054] N-benzoyl ammonium phosphate 0.5 parts

[0055] Vinyl acetate mixture 1.8 parts

[0056] Sodium bisulfate 0.8 parts.

[0057] The tapioca starch is fresh tapioca starch with an ash content of 0.18%, a moisture content of 12%, an acidity of 12, a fineness of 99%, a whiteness of 85%, a viscosity of 600BU, and a phosphorus content of 0.01%.

[0058] The production technology of the modified starch prepared by substituting tapioca starch for potato starch comprises the following processing steps:

[0059] Step (1), mix tapioca starch and water, stir evenly, the mass ratio of tapioca starch and water is 1:1, add dilute caustic soda to adjust the pH to 10.8, keep warm at 35°C, and the mass concentration of dilut...

Embodiment 2

[0064] The modified starch prepared by substituting tapioca starch for potato starch comprises the following raw materials in parts by weight:

[0065] Tapioca starch 100 parts

[0066] N-phosphoryl-N-methylimidazole 1 part

[0067] Salicyl Phosphate 1 part

[0068] 1 part N-benzoyl ammonium phosphate

[0069] 2 parts vinyl acetate mixture

[0070] Sodium bisulfate 1 part.

[0071] The tapioca starch is fresh tapioca starch with an ash content of 0.19%, a moisture content of 13%, an acidity of 13, a fineness of 99.2%, a whiteness of 86%, a viscosity of 650BU, and a phosphorus content of 0.01%.

[0072] The production technology of the modified starch prepared by substituting tapioca starch for potato starch comprises the following processing steps:

[0073] Step (1), mix tapioca starch and water, stir evenly, the mass ratio of tapioca starch and water is 1:1.1, add dilute caustic soda to adjust the pH to 10.9, keep warm at 38°C, and the mass concentration of dilute causti...

Embodiment 3

[0078] The modified starch prepared by substituting tapioca starch for potato starch comprises the following raw materials in parts by weight:

[0079] Tapioca starch 100 parts

[0080] 1.5 parts of N-phosphoryl-N-methylimidazole

[0081] Salicyl Phosphate 1.5 parts

[0082] N-benzoyl ammonium phosphate 1.5 parts

[0083] Vinyl acetate mixture 2.2 parts

[0084] Sodium bisulfate 1.2 parts.

[0085] The tapioca starch is fresh tapioca starch, with an ash content of 0.2%, a moisture content of 14%, an acidity of 14, a fineness of 99.3%, a whiteness of 87%, a viscosity of 700BU, and a phosphorus content of 0.02%.

[0086] The production technology of the modified starch prepared by substituting tapioca starch for potato starch comprises the following processing steps:

[0087] Step (1), mix tapioca starch and water, stir evenly, the mass ratio of tapioca starch and water is 1: 1.2, add dilute caustic soda to adjust the pH to 11.0, keep warm at 40°C, and the mass concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com