A kind of recovery method of solution for producing lyocell fiber

A recycling method and fiber technology, which is applied in the field of fiber production, can solve problems such as inability to remove solid or colloidal impurities and affect the normal operation of the recycling process, and achieve the effect of improving quality, appearance and physical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

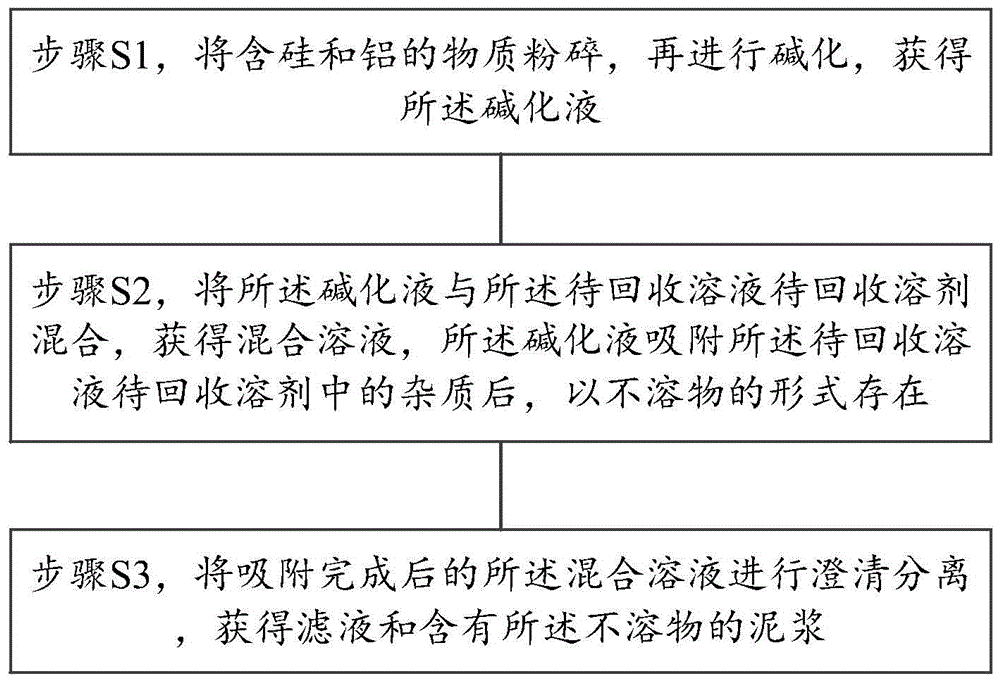

Method used

Image

Examples

Embodiment 1

[0080] The solvent to be recovered for the production of Lyocell fibers used in this implementation has a light yellow color and test indicators: electrical conductivity of 150 μS / cm (micro Siemens per centimeter), turbidity of 80 FTU, and total iron content of 2.5 ppm.

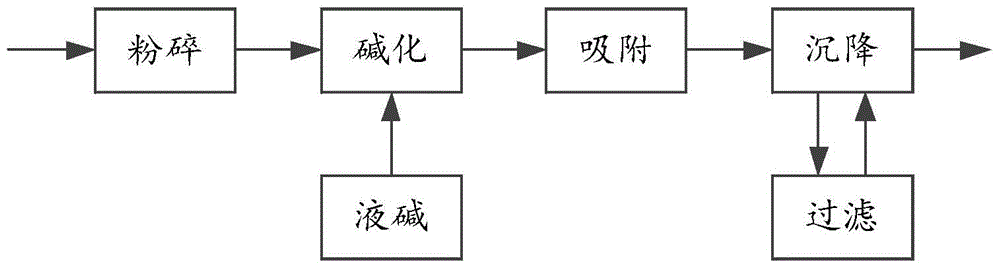

[0081] Such as figure 2 As shown, first, take 100kg of fly ash crushed to 80 meshes, add 1900kg of 2.5% NaOH aqueous solution to prepare a 5% fly ash mixed solution, heat up to 80°C, stir for 3 hours under heat preservation, and then transport to the alkalinity supply tank for use.

[0082] The solvent to be recovered is transported into the adsorption agitator at a flow rate of 1 ton / hour, and alkalized substances are added at a flow rate of 6 kg / hour, the concentration of fly ash in the solvent to be recovered is 300 ppm, and the average residence time of mixing and stirring is 18 minutes , and then transported to the Doyle-type settling tank, the clarified solution flows out from the upper layer of the s...

Embodiment 2

[0087] The solvent to be recovered for the production of Lyocell fibers used in this implementation is light yellow in color. The test indicators: conductivity 210μS / cm, turbidity 110FTU, and total iron content 3.0ppm.

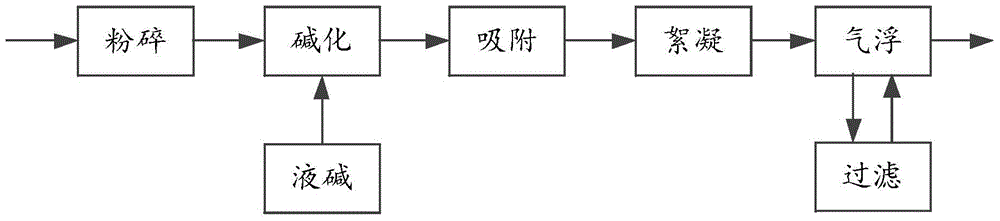

[0088] Such as image 3 As shown, first, take 1000 kg of kaolin crushed to 300 mesh, add 3000 kg of 15% NaOH aqueous solution to prepare a 25% kaolin mixed solution, raise the temperature to 102 ° C, stir for 1.5 hours under heat preservation, and then transport it to the alkalization supply Cans are ready to use.

[0089] The solvent to be recovered is transported into the adsorption mixer at a flow rate of 80 tons / hour, an alkalized compound is added at a flow rate of 256 kg / hour, the concentration of kaolin in the solvent to be recovered is 800ppm, the average residence time of mixing and stirring is 5 minutes, and then transported To the flocculation mixer, add anionic polyacrylamide accounting for 160ppm of the solvent to be recovered, mix for 0.5 minute...

Embodiment 3

[0094] The solvent to be recovered for the production of Lyocell fibers used in this implementation is light yellow in color. The test indicators: conductivity 180μS / cm, turbidity 90FTU, and total iron content 3.5ppm.

[0095] Such as Figure 4 As shown, first, take 500 kg of diatomite crushed to 150 meshes, add 4500 kg of 8% NaOH aqueous solution to prepare a 10% diatomite mixed solution, heat up to 90 ° C, stir for 3.5 hours under heat preservation, and then Transport to alkalization supply tank for use.

[0096] The solvent to be recovered is transported into the adsorption mixer at a flow rate of 5000kg / hour, an alkalized compound is added at a flow rate of 20kg / hour, the concentration of diatomaceous earth in the solvent to be recovered is 400ppm, the average residence time of mixing and stirring is 4 minutes, and then Transport to the flocculation mixer, add anionic polyacrylamide accounting for 20ppm of the solvent to be recovered, mix for 0.5 minutes, then pressurize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com