Composite nanofiber membrane and preparation method and application thereof

A technology for compounding nanofibers and nanofibers, which is applied in fiber processing, textiles and papermaking, non-woven fabrics, etc., can solve the problems of destroying the nanofiber structure, lack of wide applicability, and cumbersome processes, and achieves a simple preparation process, Reduced pressure drop and drag, cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

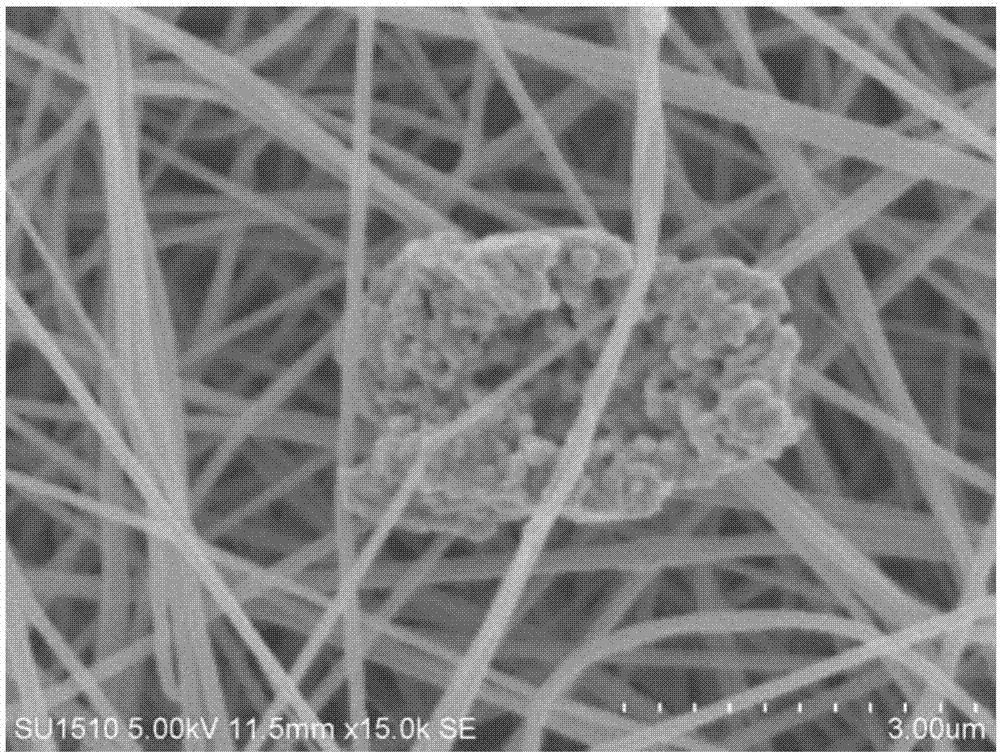

[0027] A composite nanofiber membrane is made of electrospun nanofiber deposition foaming material; the foaming material is polyvinyl alcohol.

[0028] A method for preparing a composite nanofibrous membrane, comprising the following steps:

[0029] Step 1, preparation of electrospinning solution: dissolving polyamide-6 in formic acid solution, stirring mechanically at a speed of 200 r / min for 10 h at room temperature to prepare a solution with a mass fraction of 20%, and standing to remove air bubbles;

[0030] Step 2. Preparation of electrostatic spray solution: Dissolve 0.4g polyacrylcyanide in 19.6g N,N-dimethylformamide, stir well to dissolve, add 0.5g sodium bicarbonate, stir ultrasonically, fully disperse, and let stand to remove Bubble;

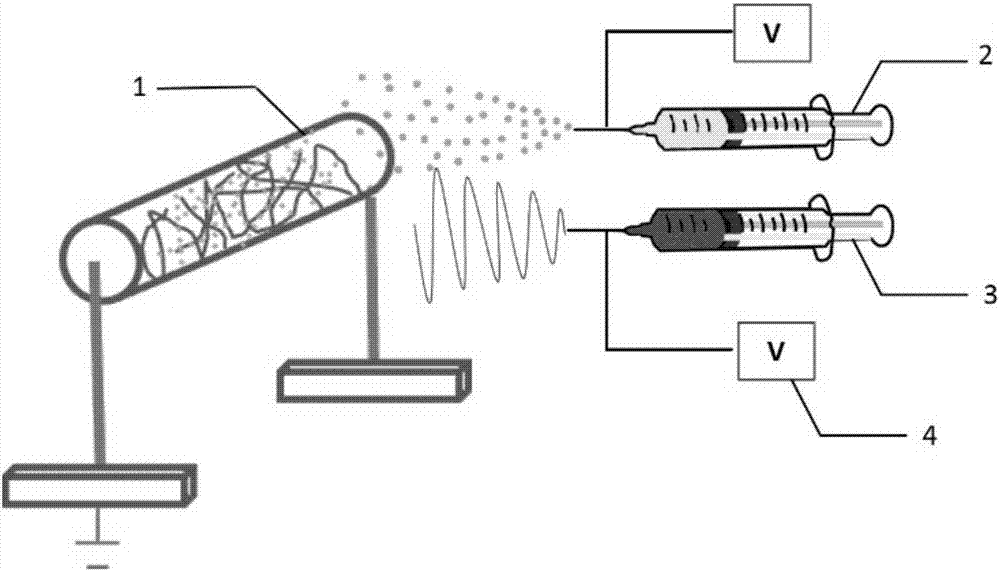

[0031] Step 3, preparation of composite nanofiber membrane: the electrospinning solution prepared in the first step is placed in the syringe 3 for electrospinning, and the electrostatic spray solution prepared in the second step is p...

Embodiment 2

[0035] A composite nanofiber membrane is made of electrospun nanofiber deposition foaming material; the foaming material is polyethylene.

[0036] Step 1, preparation of electrospinning solution: dissolve polyacrylonitrile in dimethylformamide solution, mechanically stir at a speed of 600r / min at room temperature until completely dissolved, and make a solution with a mass fraction of 10%, and let it stand remove air bubbles;

[0037] Step 2, preparation of electrostatic spray solution: Dissolve polyethylene in toluene under a water bath condition of at least 70°C, prepare 20 g of electrostatic spray solution with a mass fraction of 3%, let it stand for defoaming, add 0.2 calcium carbonate after cooling, Ultrasonic stirring until uniform dispersion;

[0038] Step 3, preparation of composite nanofiber membrane: the electrospinning solution prepared in the first step is placed in the syringe 3 for electrospinning, and the electrostatic spray solution prepared in the second step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com