Putter face configuration with progressively increasing loft

a technology of putter face and progressively increasing loft, which is applied in the field of putter type golf clubs, can solve the problems of affecting accuracy, ball bouncing and skidding instead of rolling smoothly, and affecting ball bouncing and rolling, so as to achieve negative loft, increase loft, and increase loft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

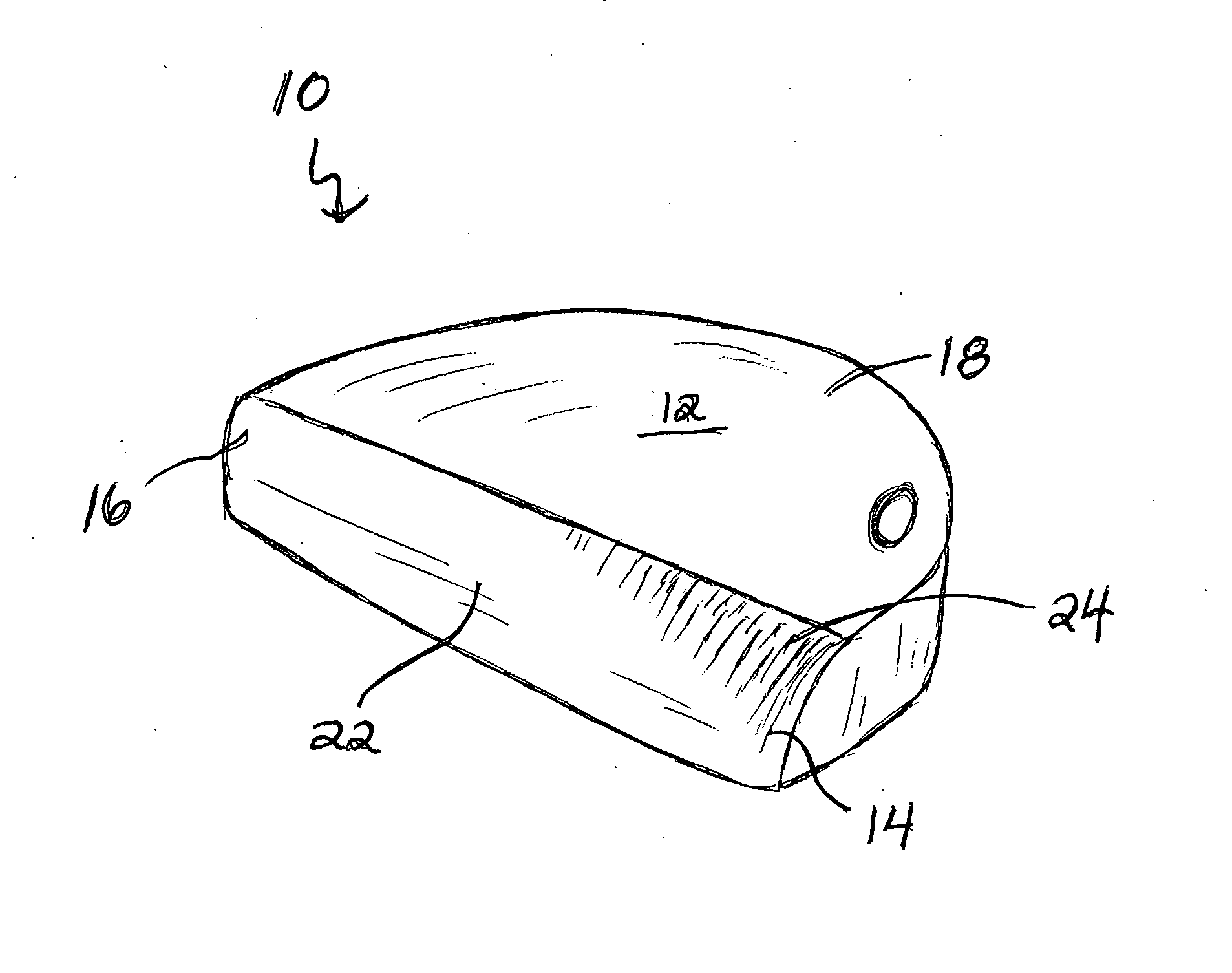

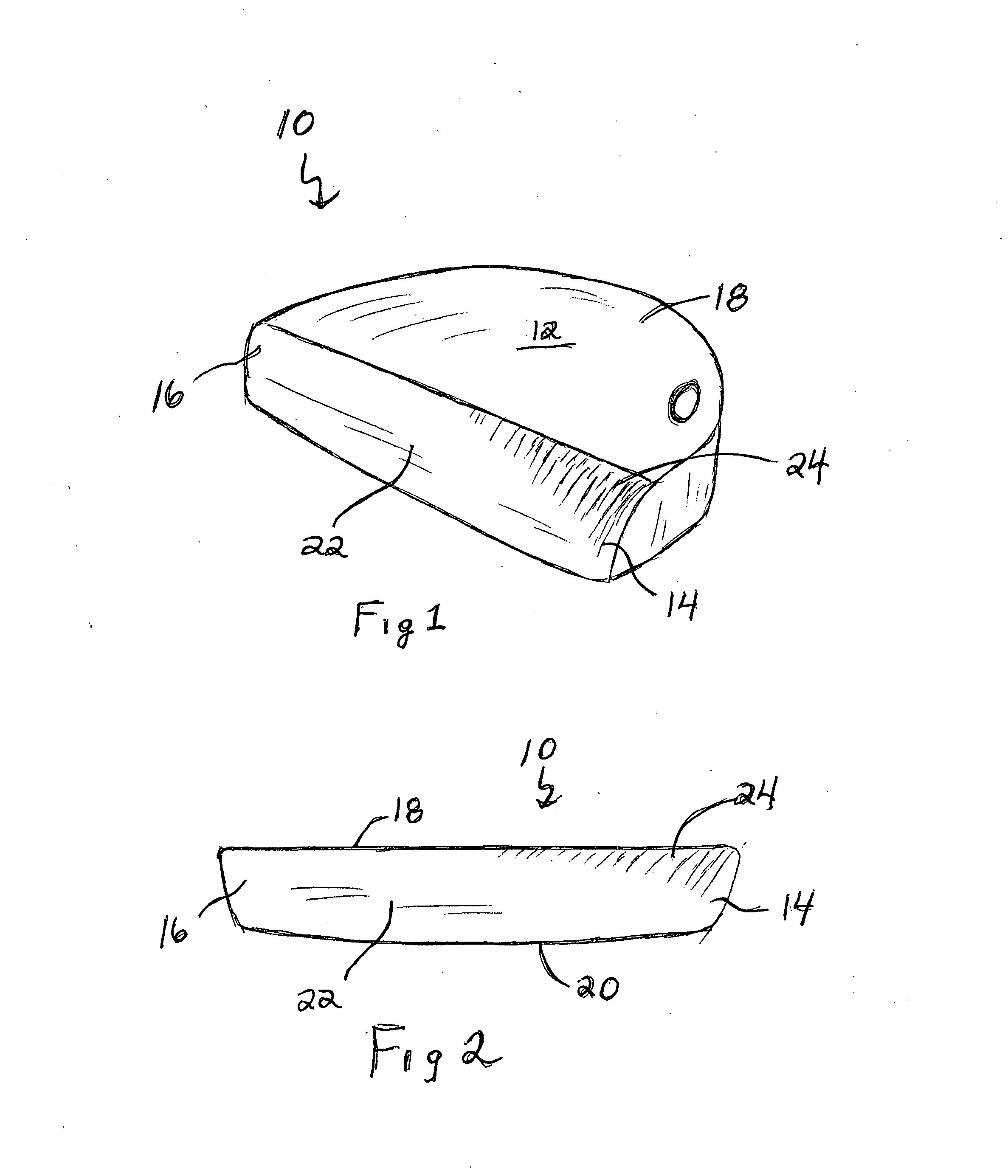

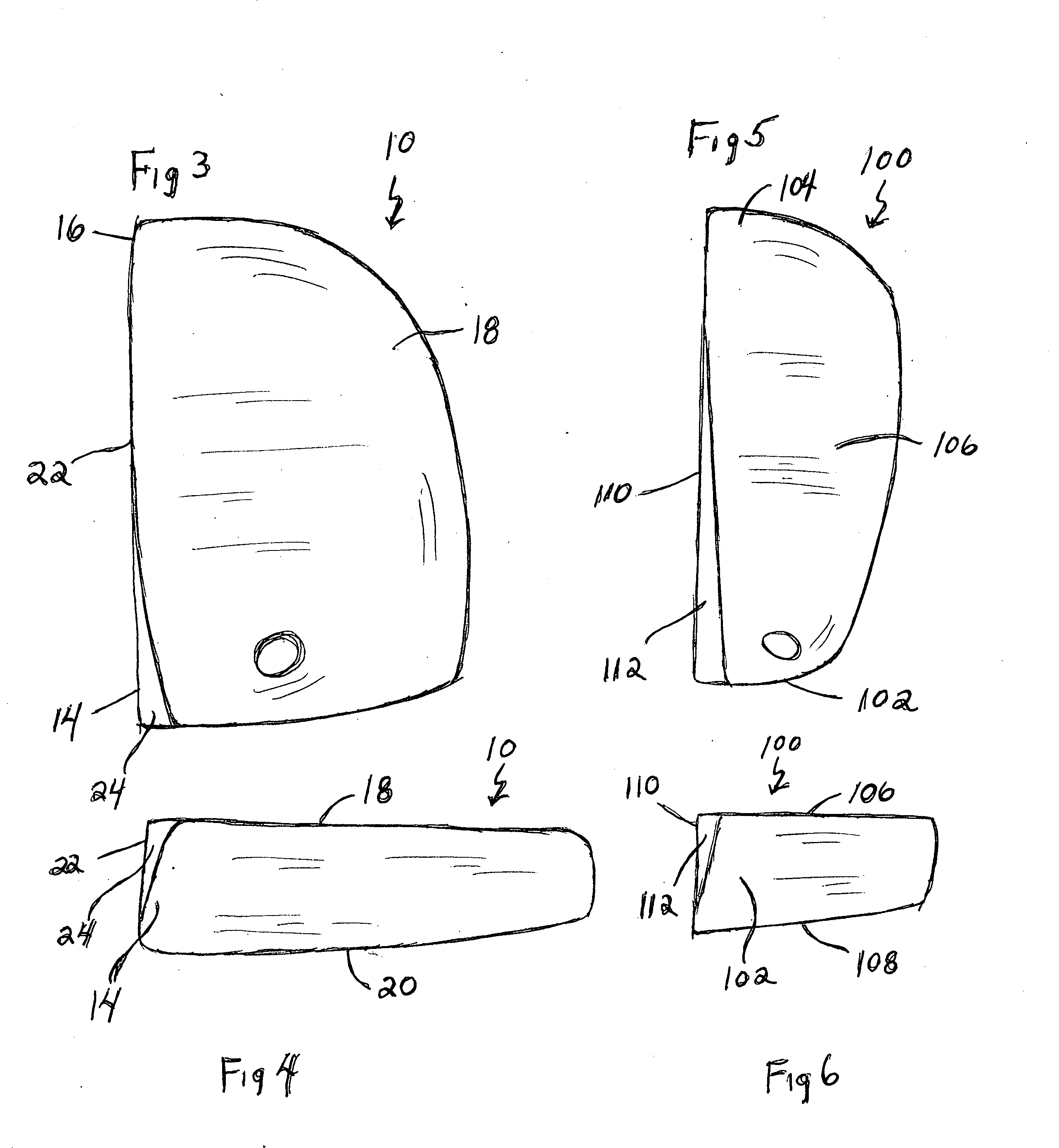

[0019]In accordance with the present invention, a putter type golf club is formed with a frontal ball striking face characterized by a progressively increasing loft angle on the striking face toward the heel. Referring to the drawings, a putter type golf club head 10 includes a club head body 12, having a heel 14, toe 16, top surface, 18 bottom sole 20 and frontal ball striking face. 22. The face 22 has a conventional loft of approximately 4 degrees between the bottom sole 20 and the top surface 18 across a significant part of the striking face 22. In the present embodiment the striking face 22 is formed with slight curvature between the heel 14 and toe 16. Preferably this radius is 80 inches across the face 22. Although this embodiment is shown with a slight curvature, it will be appreciated the entire face may be generally flat or planar from the heel to the toe creating a flat face design.

[0020]In the preferred embodiment shown, the striking face 22 has an area 24 of increased lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com