Warping system and warping method

A warping system and warping machine technology, applied in the warping system and the field of warping, can solve the problems of reduced production efficiency, disorder, temperature, humidity and other conditions changes, achieve small relative errors, reduce chaos or disorder, and reduce preparations effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] best practice

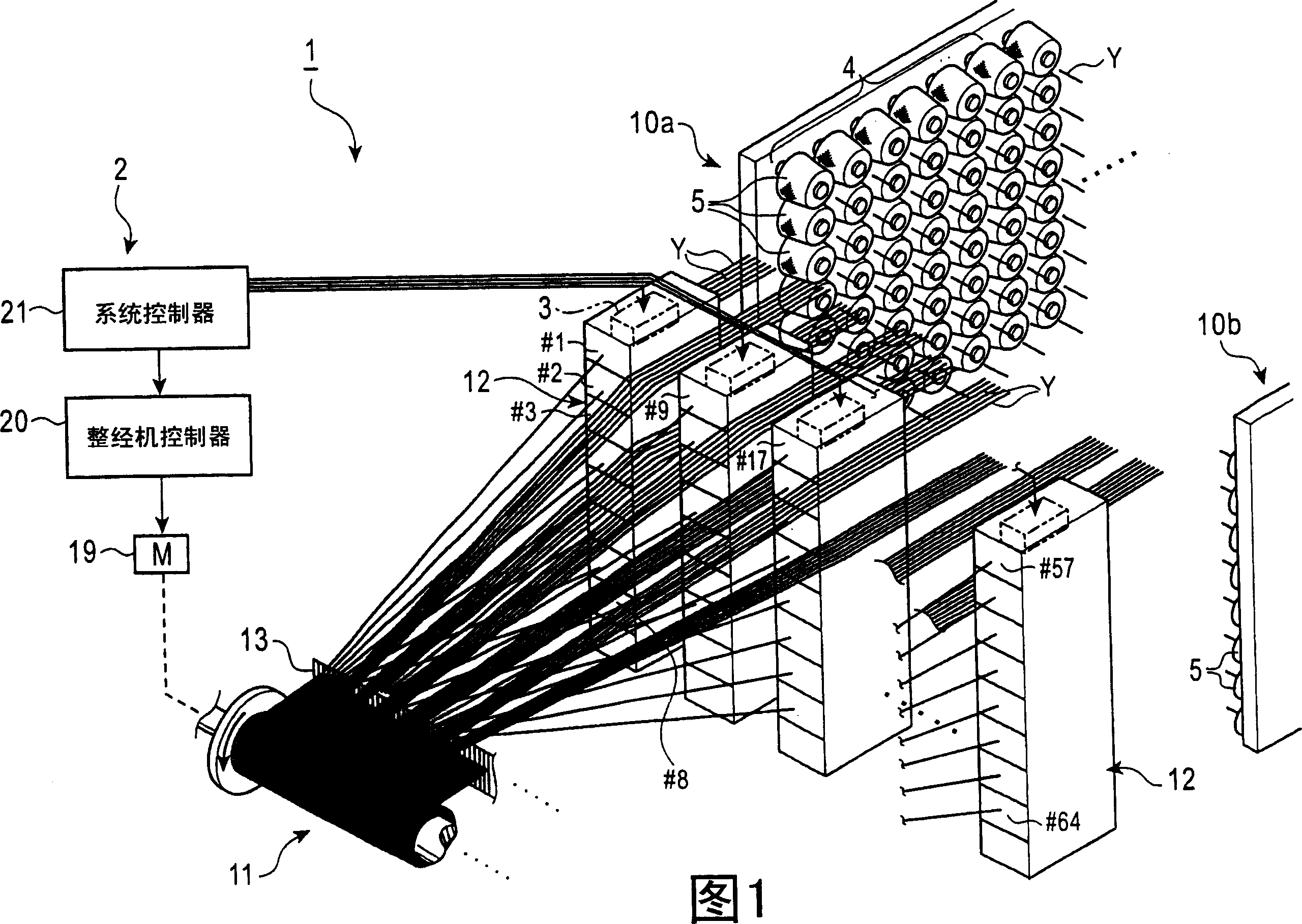

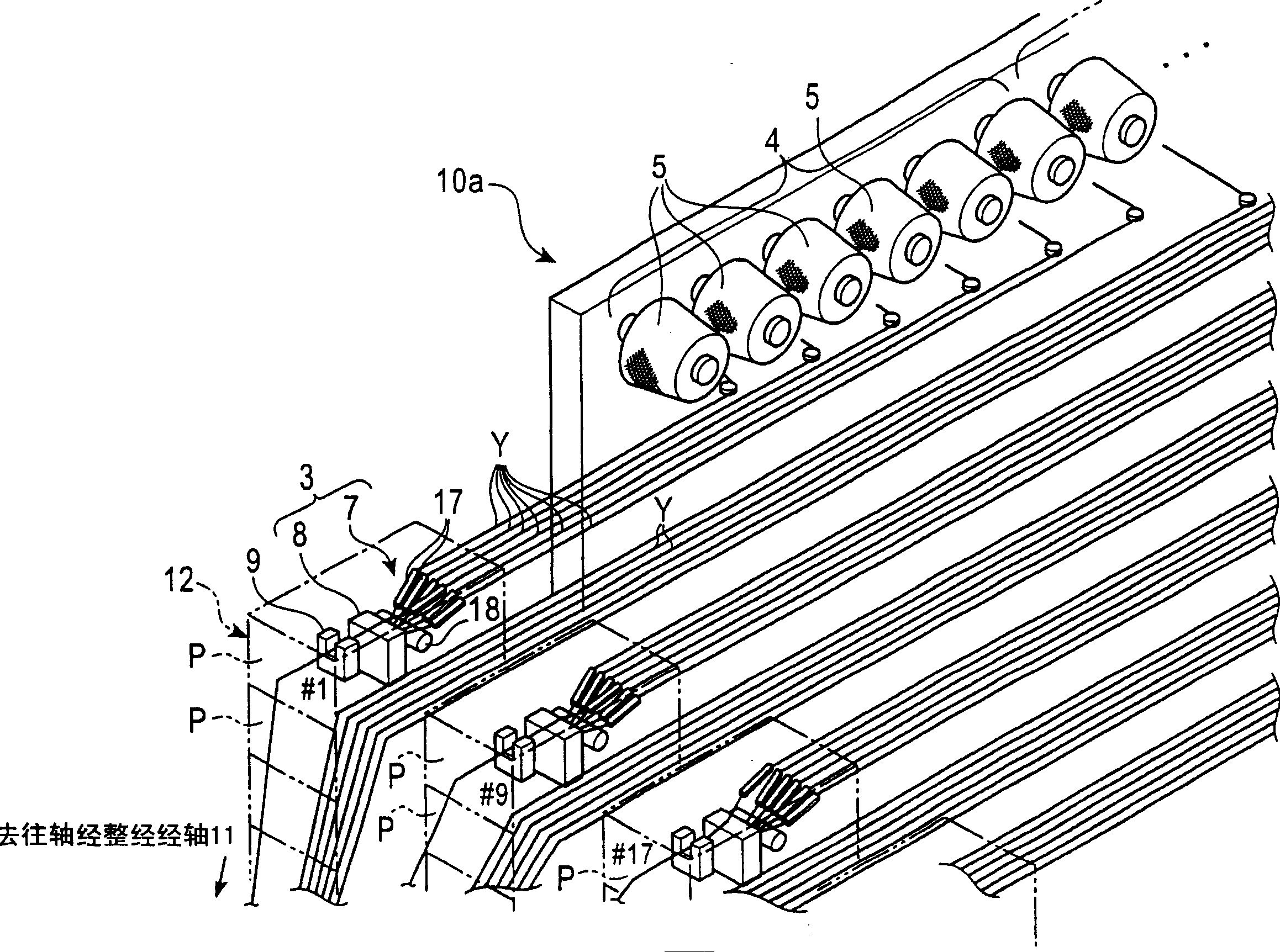

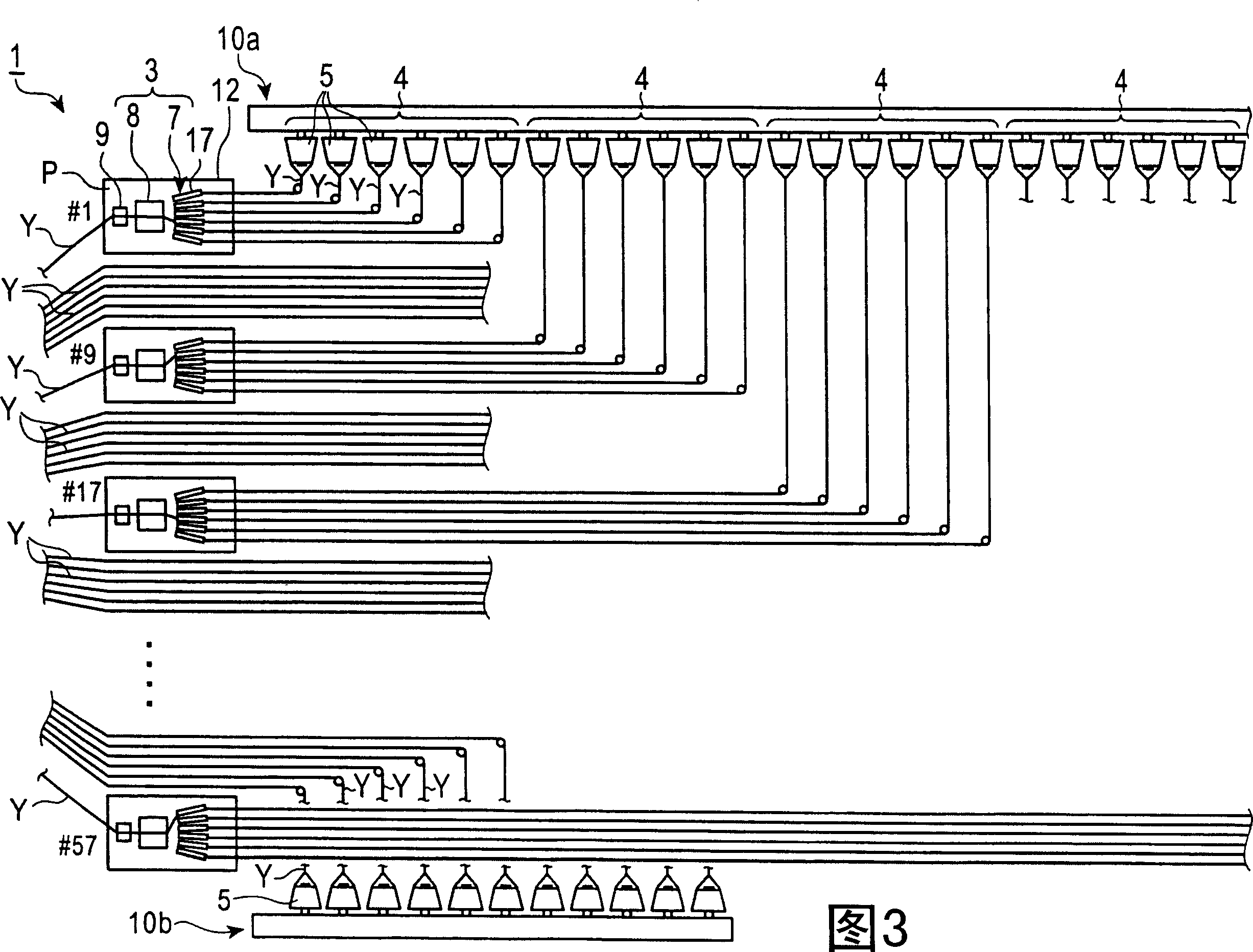

[0039] Embodiments of the invention will be described below. Fig. 1 is a perspective view showing the overall structure of a beam warping system related to an embodiment of the present invention, figure 2 Fig. 3 is an enlarged perspective view showing how a warp yarn group is supplied from a package group to a yarn switching mechanism, and Fig. 3 is a plan view showing an overall structure of a beam warping system according to an embodiment of the present invention, Figure 4 It is a longitudinal sectional view showing the appearance and arrangement of the yarn switching mechanism.

[0040]Fig. 1 shows a perspective view of the whole of the beam warping system. 2. The warping creel 10b and the beam warping machine 2 that winds hundreds of warp yarns Y unwound from the yarn feeding package 5 in parallel to form a beam warping beam 11.

[0041] In addition, the beam warping system 1 is provided with a plurality of warping beams for accommodating multipl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com