Warping knitting sectional copy warping machine

A warping machine and slitting technology, applied in warping machines, other manufacturing equipment/tools, textiles and papermaking, etc., can solve problems such as multiple heads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing as follows.

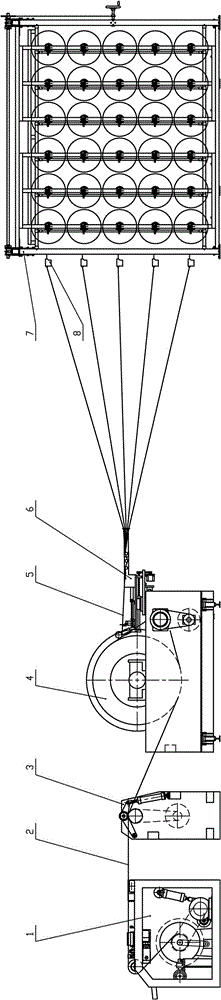

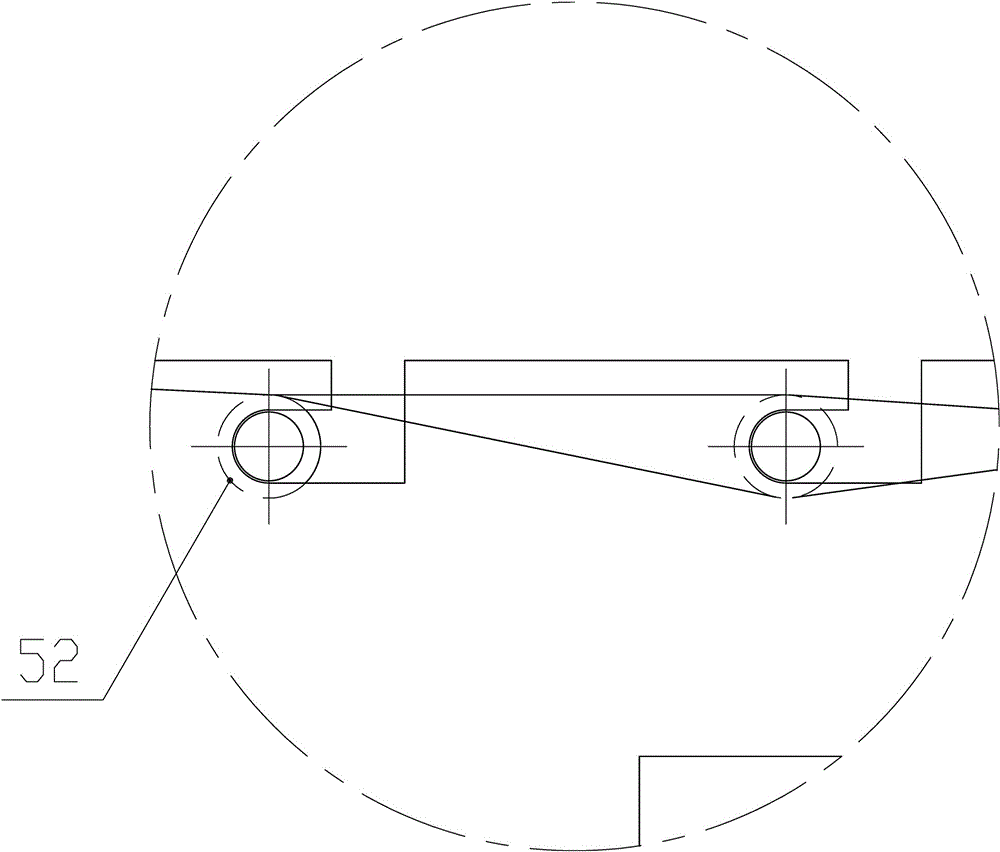

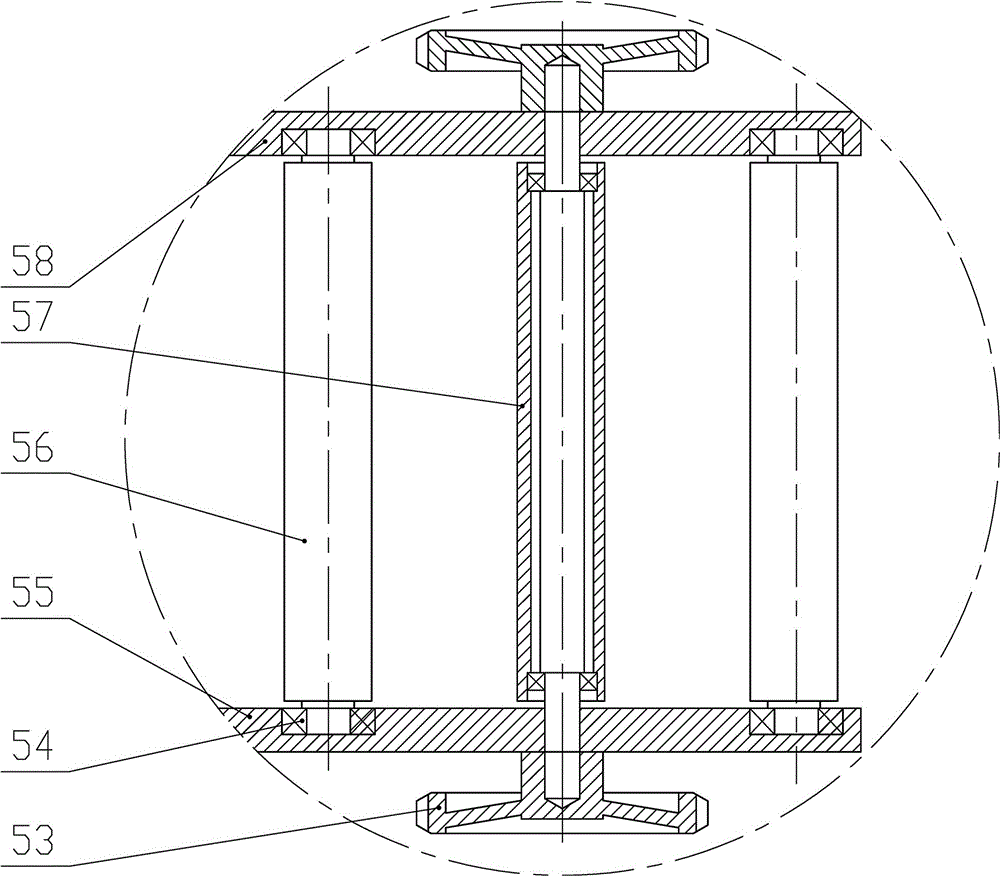

[0026] Such as Figure 1-11As shown, the warp knitting section copy warping machine includes: a warp knitting section copy warping machine, including a creel 7, a warping table 6, a winding device 4, a traction device 3, an inverted shaft device 1 and an electric control The central composition is characterized in that the total head portion of the pan head 46 is determined according to the requirements of the slitting process, and the bobbins 9 on the creel 7 with fewer head portions are guided through the tensioner 10 and passed through the yarn breaking automatic stop device 8, Leading into the wire collecting plate 16 on the warping table 6 of the winding device 4 supported by four wheels 18 on the guide rail 17, and then passing through the tension balance roller device 15 to form a sheet-shaped sliver 5, and then twisting through the splitting device 14 Final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com