Stitch slipping resisting light and thin fancy crepe georgette shell fabric and weaving method thereof

A double-joe de crepe and anti-slip technology, which is applied in textiles, papermaking, fabrics, textiles, etc., can solve the problems of high price of double-joe de crepe fabrics, increase production and raw material costs, and lose the excellent characteristics of light and thin fabrics, and achieve easy marketability Promote the application, improve the technological content, and the effect of not being easy to pull wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

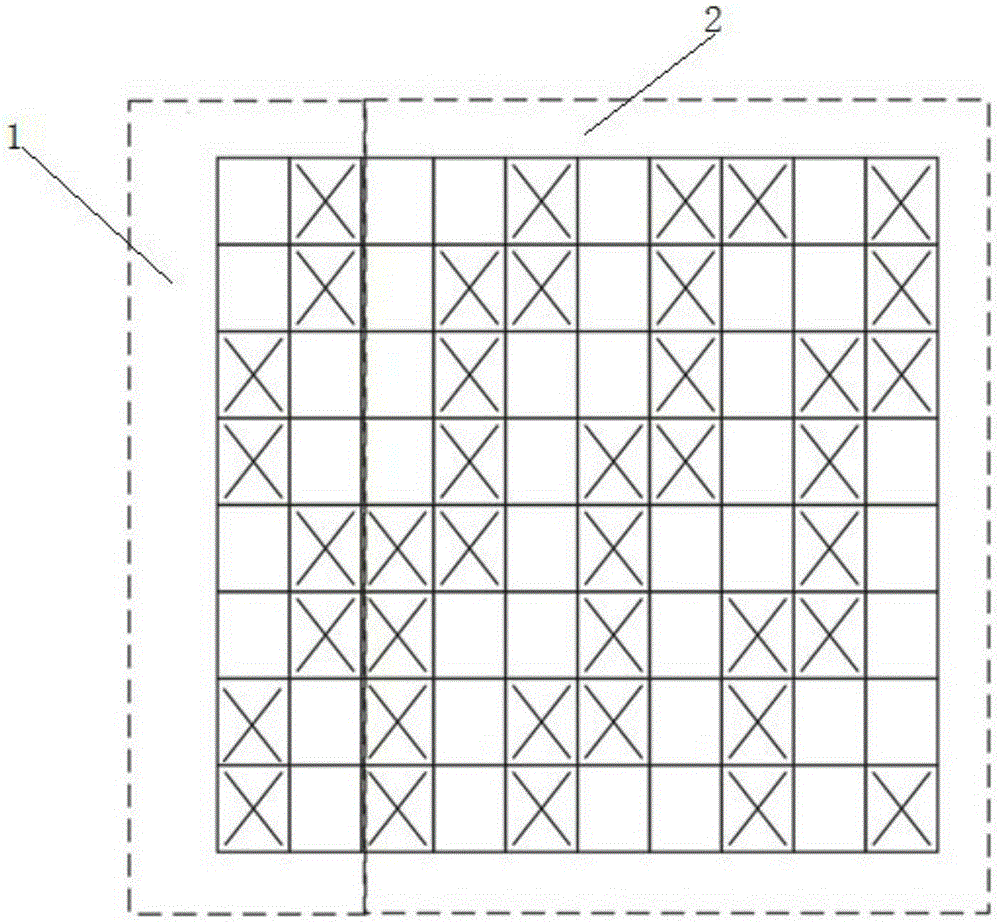

[0028] combine figure 1 , the invention discloses a light and thin crepe crepe fabric with anti-slip, which is formed by interweaving warp and weft; the warp is 20 / 22 denier silk of 26T / 2S2Z, and the weft is 20 / 22 of 26T / 1S1Z Denier silk; the warp density of the anti-slip light and thin double georgette fabric is 86 threads / cm; the weft density of the anti-slip light and thin double georgette fabric is 60 threads / cm; the anti-slip light and thin double The inner weave of crepe crepe fabric is eight changing twill weaves, and the side weave has two upper and two lower heaves flattened. combine figure 1 , the inner weave 1 is eight pieces of changing twill, and the side weave 2 is two upper and two lower through heavy flattening, and the upper floating point in the figure is used In the figure, the lower and lower floating points are represented by "□", and the texture of the fabric is expressed through the combination of upper and lower floating points. The specifications o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com