Method of producing high-grade shift fabric interwoven with recycled polyester filament yarns and modal cotton

A technology of recycled polyester and production methods, which is applied in the field of high-grade shirt fabrics, can solve the problems of fabric foaming and wrinkling, and achieve the effects of shortening the production cycle and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

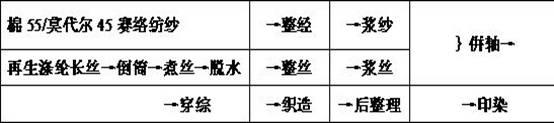

[0017] The production method of regenerated polyester filament and cotton 55 / modal 45 siro yarn interweaving high-grade shirting fabric comprises the following steps:

[0018]

[0019] 1. Cotton 55 / Modal 45 siro-spun yarn:

[0020] According to the shrinkage changes of cotton single yarn and modal yarn after dyeing, the dimensional stability of pure cotton yarn after dyeing is relatively good, and the shrinkage rate is about 1%. Compared with viscose fiber, modal fiber has been greatly improved in strength and other aspects. However, the shrinkage of modal yarn after dyeing is close to 10% or even greater than that of viscose yarn. By analyzing the difference in shrinkage after dyeing of cotton yarn and modal yarn, the inconsistency of these two raw materials is fully utilized. The two raw materials are mixed according to different ratios, and finally it is determined that the ratio of cotton and modal is the most favorable according to the ratio of cotton 55 / modal 45, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com