Weaving process for aloe fiber small jacquard fabric

A technology of small jacquard fabric and aloe fiber, which is applied in the field of fabric weaving, can solve the problems of lack of health care function and environmental protection, and achieve the effect of clear grid and pattern, bright color and smooth cloth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

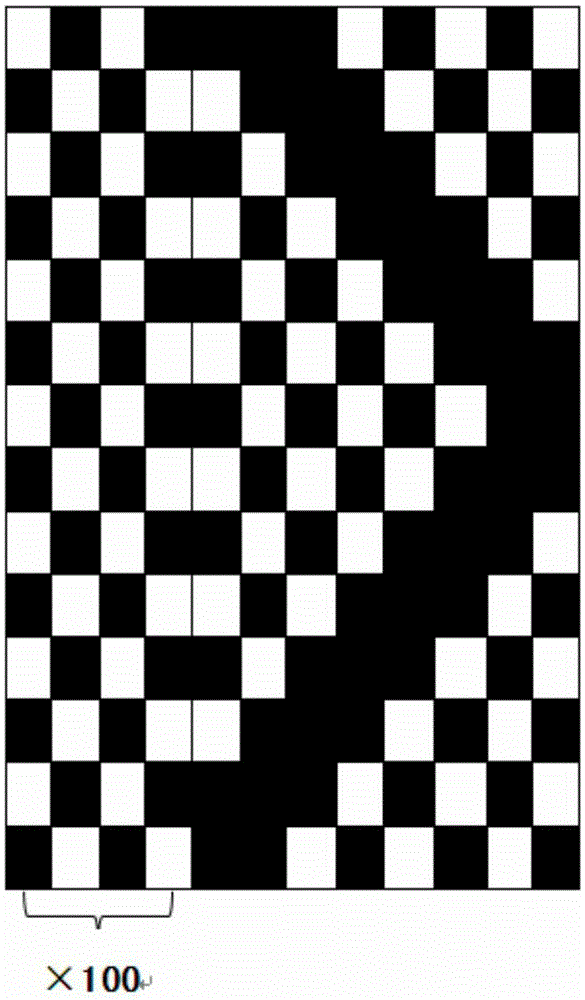

[0021] Such as figure 1 As shown, a weaving process of aloe fiber small jacquard fabric includes the following steps: winding process-warping process-sizing process-drawing-in process-weaving process;

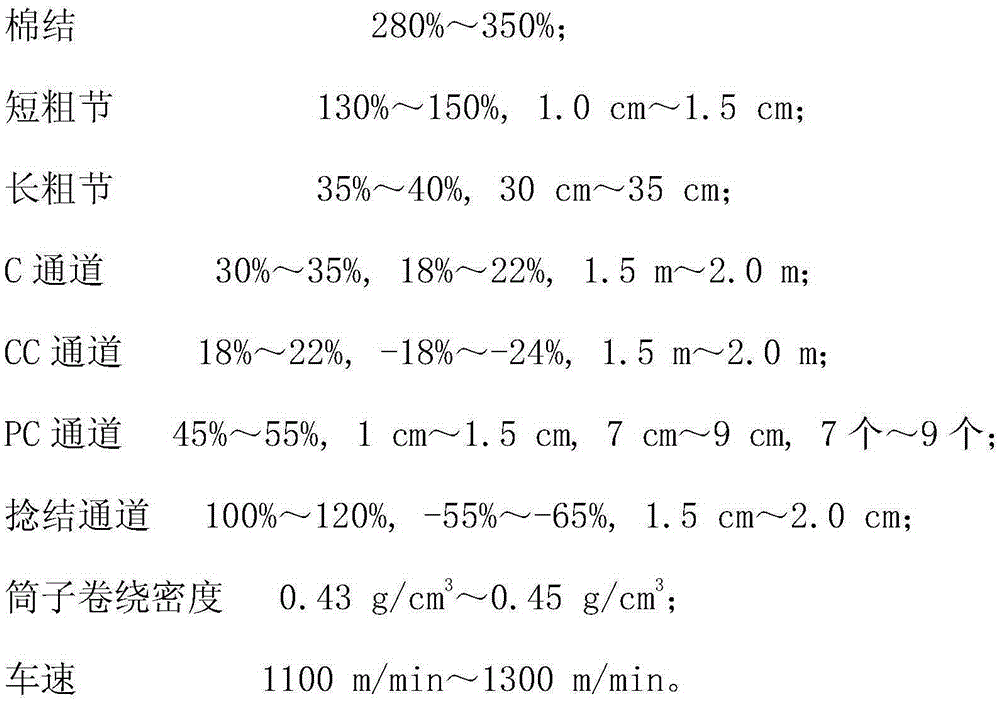

[0022] The winding process adopts AUTOCONER338 type winding machine, and the various process parameters are as follows:

[0023]

[0024] The warping process uses a Benninger section warping machine with a speed of 300m / min, a reversing speed of 350m / min, and a winding density of 0.51g / cm 3 , The number of twists per twist is 1 flower, the number of warp yarns per twist is 418, the number of warping twists is 18, the first twist is 478, the second to 17 twists are 418, and the 18th twist is 364.

[0025] In the sizing process, the sizing formulation is as follows: animal glue 25kg, carboxymethyl cellulose CMC 25kg, glycerol 0.5kg, saponified mineral oil 1kg, penetrant JFC 0.5kg, 2-naphthol 0.5kg.

[0026] Said sizing process: using Tsudakoma HS20-Ⅱ sizing machine, size tank temperature...

specific Embodiment 2

[0034] Such as figure 1 As shown, a weaving process of aloe fiber small jacquard fabric includes the following steps: winding process-warping process-sizing process-drawing-in process-weaving process;

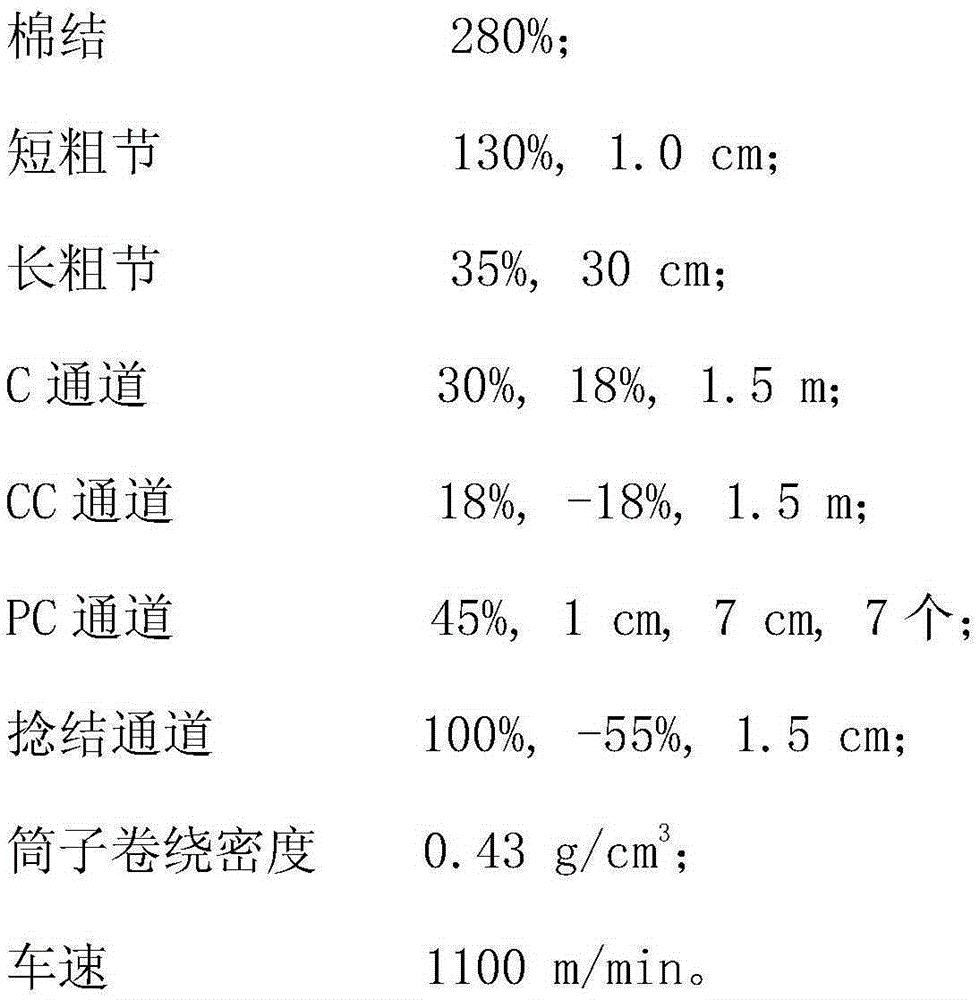

[0035] The winding process adopts AUTOCONER338 type winding machine, and the various process parameters are as follows:

[0036]

[0037] The warping process uses a Benninger section warping machine with a speed of 400m / min, a rewinding speed of 450m / min and a winding density of 0.54g / cm. 3 , The number of twists per twist is 1 flower, the number of warp yarns per twist is 418, the number of warping twists is 18, the first twist is 478, the second to 17 twists are 418, and the 18th twist is 364.

[0038] In the sizing process, the sizing formulation is as follows: animal glue 30 kg, carboxymethyl cellulose CMC 30 kg, glycerin 1 kg, saponified mineral oil 1.5 kg, penetrant JFC 1 kg, 2-naphthol 1 kg.

[0039] Said sizing process: using Tsudakoma HS20-Ⅱ sizing machine, size tank temperatu...

specific Embodiment 3

[0047] Such as figure 1 As shown, a weaving process of aloe fiber small jacquard fabric includes the following steps: winding process-warping process-sizing process-drawing-in process-weaving process;

[0048] The winding process adopts AUTOCONER338 type winding machine, and the various process parameters are as follows:

[0049]

[0050] The warping process uses a Benninger section warping machine with a speed of 360m / min, a reversing speed of 420m / min, and a winding density of 0.53g / cm. 3 , The number of twists per twist is 1 flower, the number of warp yarns per twist is 418, the number of warping twists is 18, the first twist is 478, the second to 17 twists are 418, and the 18th twist is 364.

[0051] In the sizing process, the sizing formulation is as follows: animal glue 29kg, carboxymethyl cellulose CMC 26kg, glycerin 0.8kg, saponified mineral oil 1.3kg, penetrant JFC 0.7kg, 2-naphthol 0.6kg.

[0052] The sizing process: using Tsudakoma HS20-Ⅱ sizing machine, size tank temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com