Beaming method of warp shaft

A warp yarn and yarn shaft technology is applied in the warping field of warp yarn shafts, which can solve the problems of heavy burden, time-consuming, complicated and other problems, and achieve the effect of rapid operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

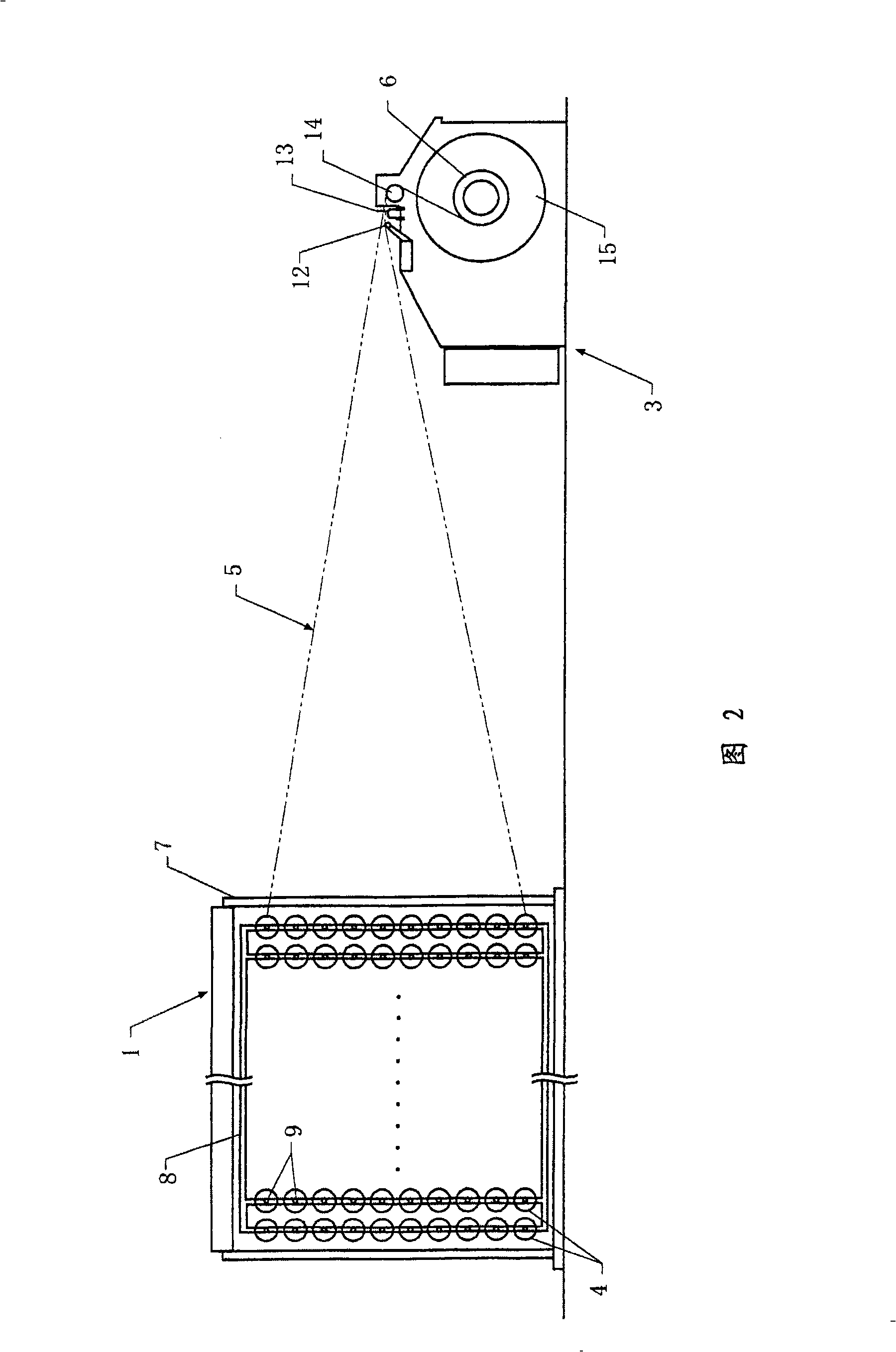

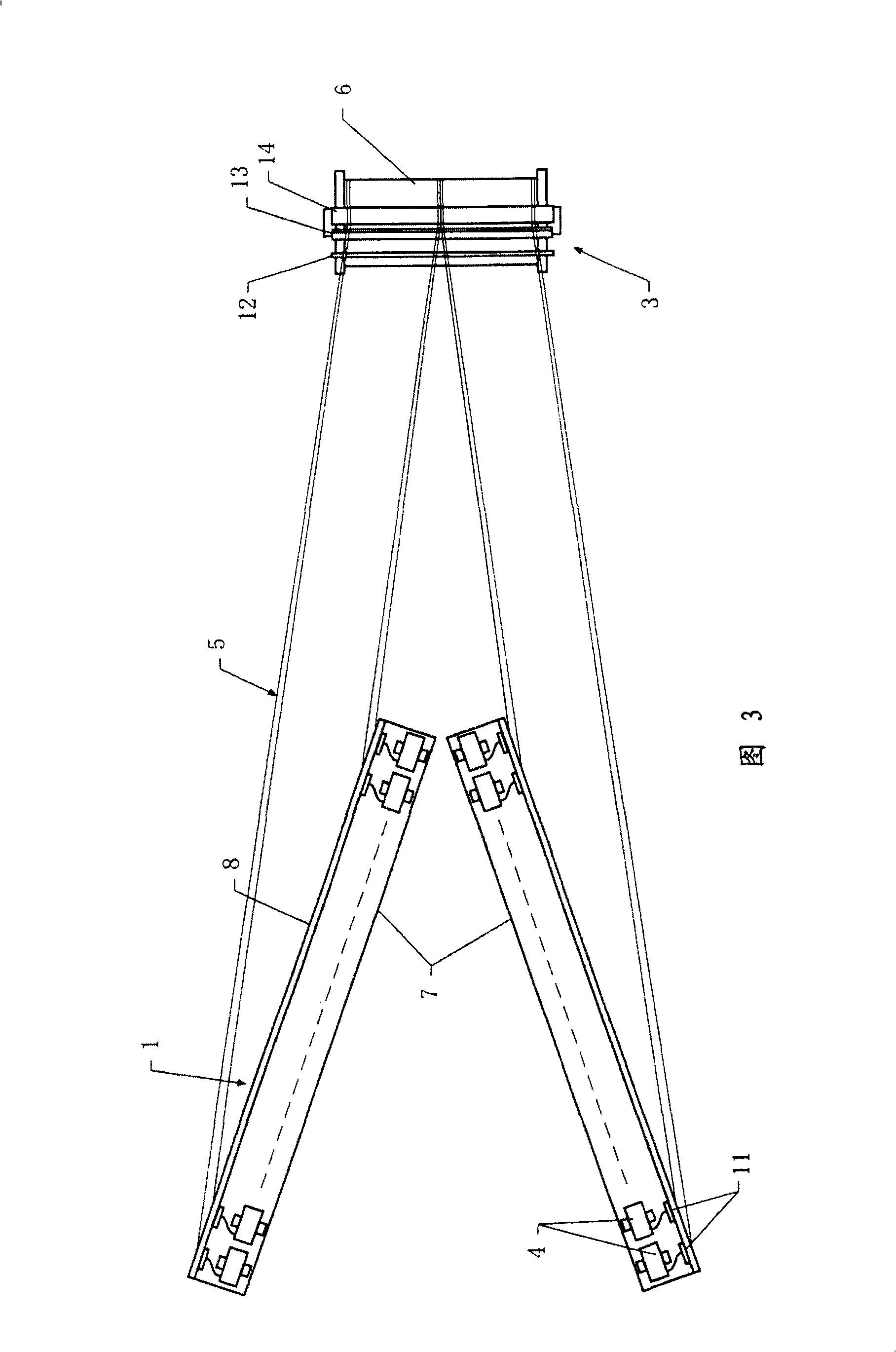

[0024] As shown in Figure 2 and Figure 3, the warping device used in the warping method of the warp beam is composed of a warp creel device 1 and a winding device 3 as main devices. The yarn body 4 draws out the yarn group 5 , and after the yarn group 5 is arranged into a sheet shape, it is wound by the winding device 3 to form a warp beam 6 .

[0025] The warp creel device 1 has a V-shaped machine frame 7 for supporting a plurality of yarn supply bodies 4, and the yarn supply body frame 8 is fixed on the inside of the machine frame 7. M×N yarn supply bodies 4 are rotatably supported approximately around the horizontal axis 9 at intervals. The yarn drawn from each yarn supply body 4 forms a yarn group 5 via a yarn cut sensor 11 provided near the yarn supply body 4, and is led toward the winding device 3 side.

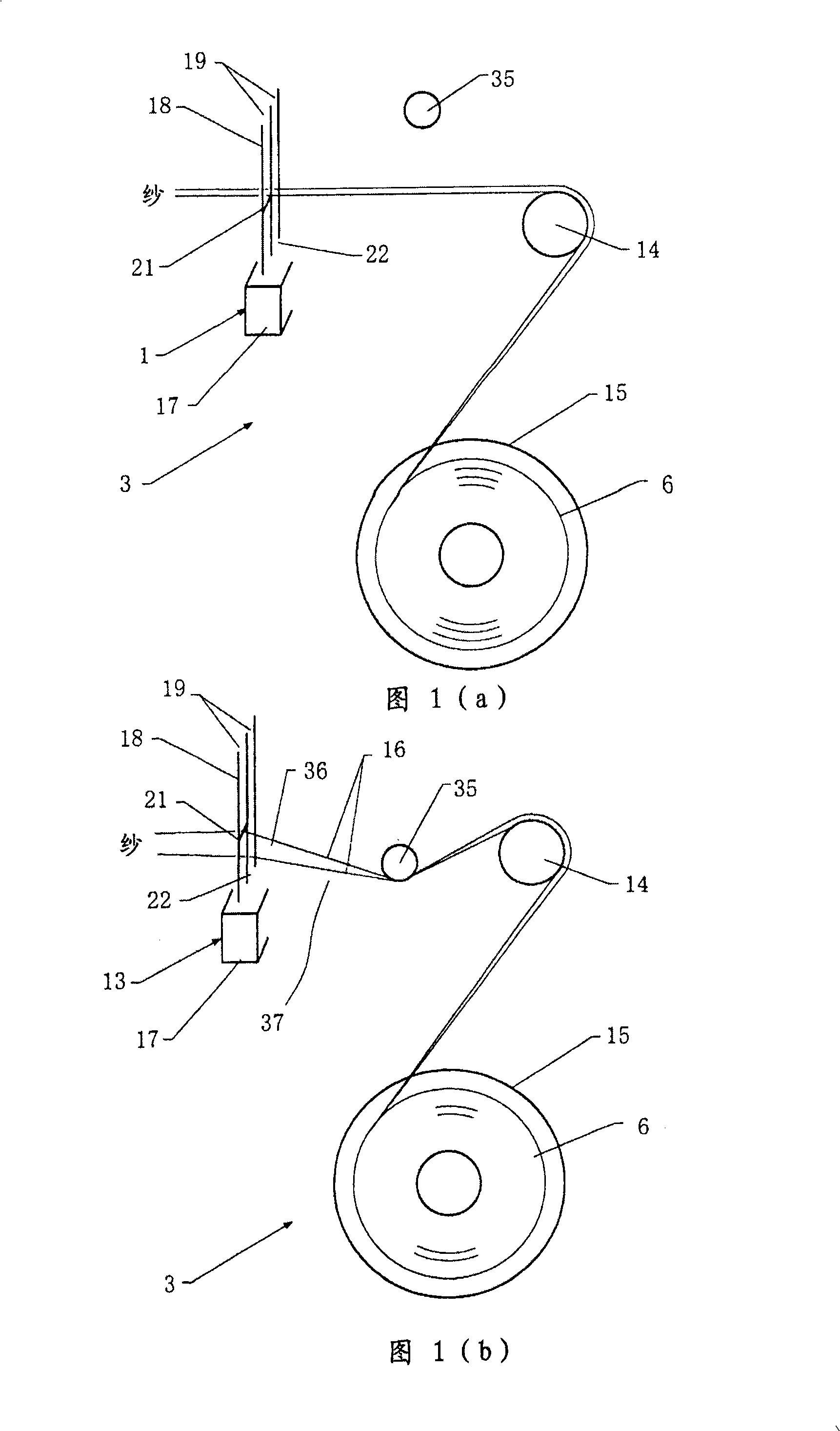

[0026] In the winding device 3 , a guide 12 , a reed 13 , and a guide roller 14 are sequentially arranged at intervals from the upstream side to the downstream side, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com