Production process for color-mixing denim and the color-mixing denim made thereby

A production process and technology of denim, which is applied in the field of textile printing and dyeing, can solve the problems that it is difficult to maintain the rough and simple style of denim, the rules of arrangement and combination are not easy to control, and the workload of repetitive labor is large, so as to achieve rich patterns and reduce repetitive labor. , fashionable effect

Inactive Publication Date: 2008-10-22

刘林泉

View PDF4 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These technologies have their respective advantages, but their disadvantages are: 1. Reprinting on the woven cloth, the process technology is complicated, the repetitive labor workload is large, the production efficiency is low, and the production cost is high.

2. Denim is woven with slub yarn, thick and thin yarn and ordinary plain yarn in a certain ratio. Although the pattern is natural, its arrangement and combination rules are not easy to control

3. The mixed-color patterns produced by printing on the woven fabrics are often brighter, and it is difficult to maintain the unique rough and simple style of denim fabrics.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

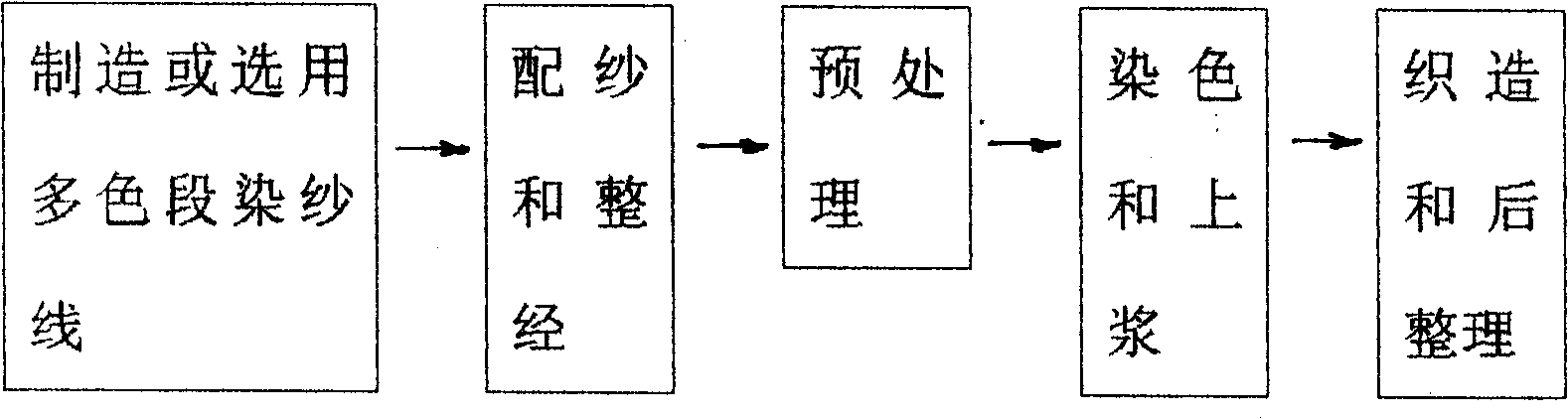

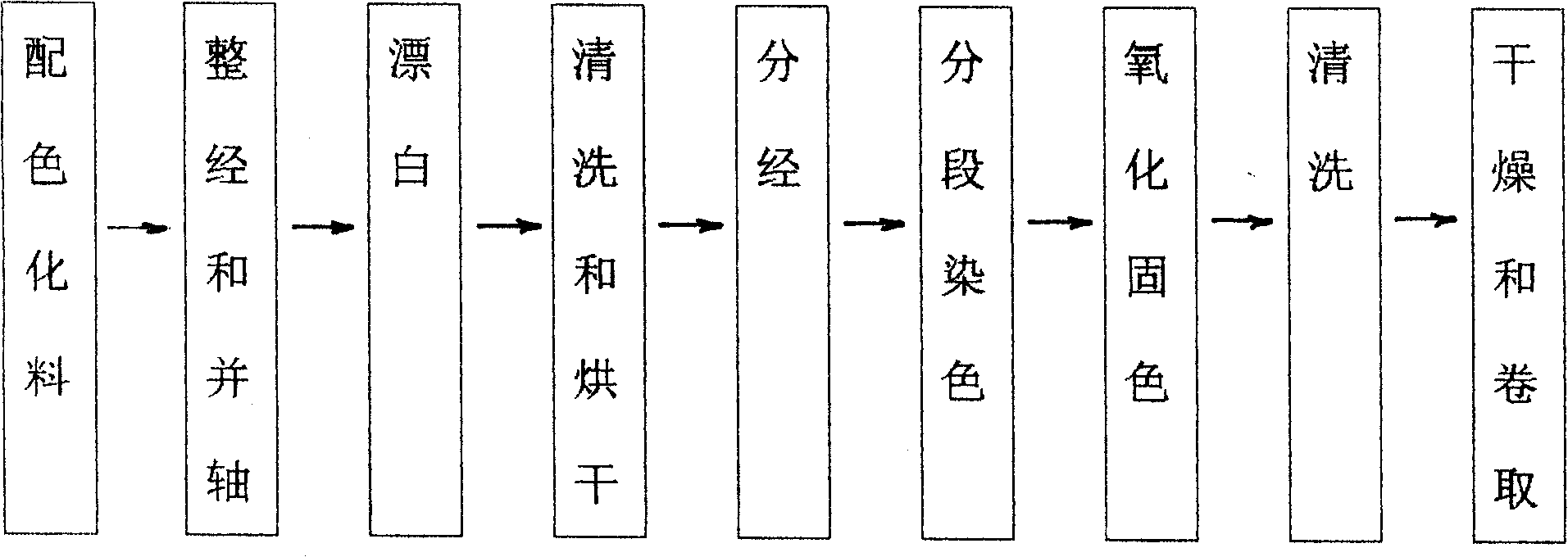

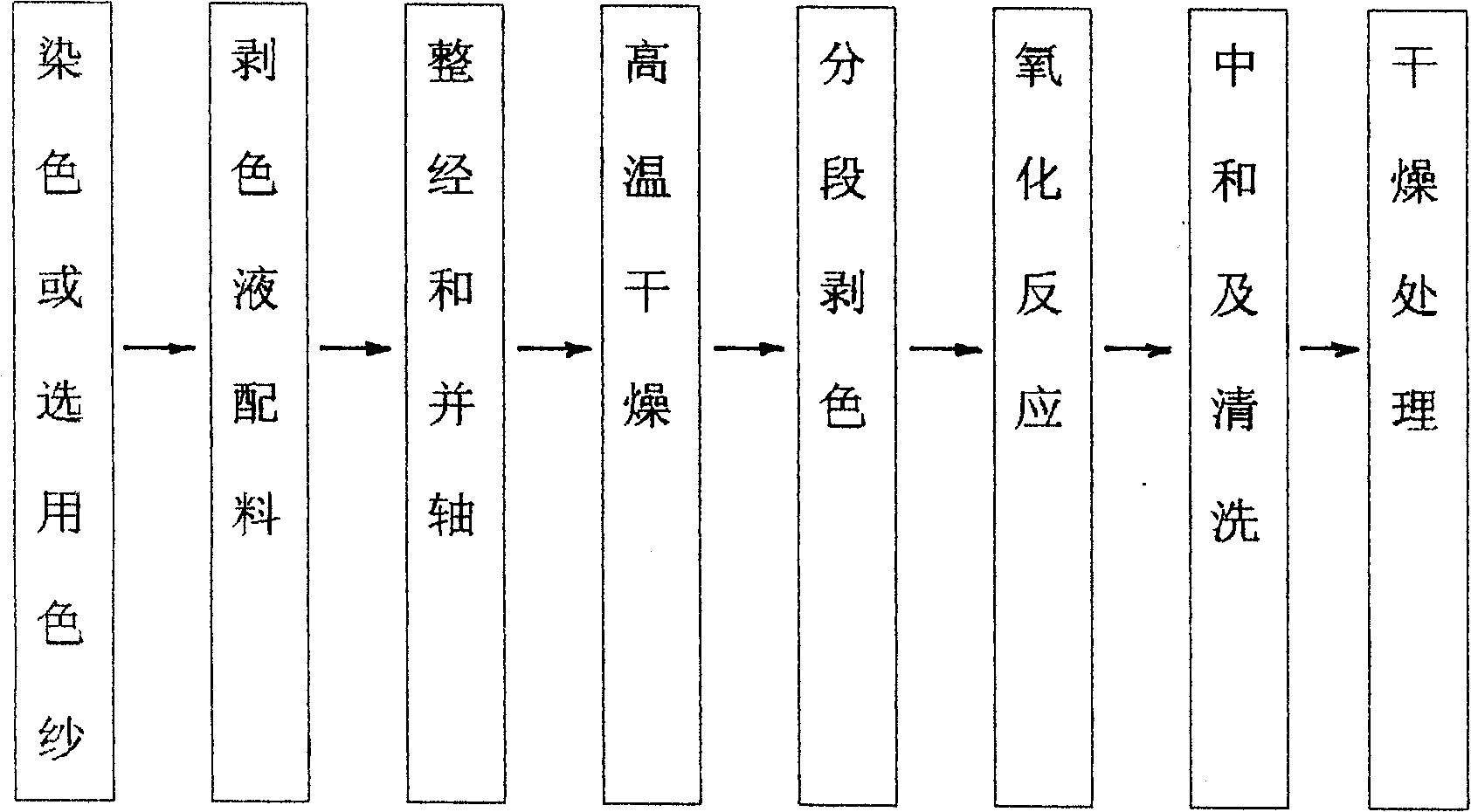

The invention relates to mixed denim and a technique for producing the same. The technique is as follows: firstly, multi-color segment dyeing yarns are adopted to be arranged and combined into bottom colored flower patterns of the denim; secondly, a main fundamental color required by the denim is dyed for the second time on a surface layer of the denim yarns; thirdly, partial colors on the surface layer of the denim are locally peeled off and internal colors of the yarns and the bottom colored flower patterns of the denim are exposed, thereby the mixed effect that the boundary of the flower patterns is blurred and the color is soft is protruded. The technique for producing the mixed denim comprises the following steps of: production of the multi-color segment yarns, yarn mixing and warping, pretreatment, dyeing and sizing, weaving and after finishing. The mixed flower patterns reach the effects of roughness, rusticity, rich color, softness and naturalness, and the techniques such as flower production, dyeing, sizing and so on can be finished once simultaneously, thereby the technique reduces labor duplication, saves a great deal of energy and can obviously reduce the production cost and the pollution of the mixed denim and the multi-color segment dyeing yarns.

Description

A kind of production technology of mixed color denim and the mixed color denim made of it technical field The invention belongs to the technical field of textile printing and dyeing, in particular to a production process of mixed-color denim and the prepared mixed-color denim. Background technique At present, the patterns of clothing and textiles are mainly produced by jacquard or printing or spraying on the woven fabrics, while the popular patterns of denim fabrics are usually produced by using slub yarns, thick yarns and ordinary plain yarns. A certain ratio, after dyeing and sizing by a sizing and dyeing machine, weaves into fabrics, and then washes and scrubs to remove part of the color of the yarn surface; or dyes the main color of the fabric on the woven gray fabric. The base color is printed with patterns of different colors. The patent application number is 200510094250.7 discloses a production process of colored denim, which is to divide thousands of cotton yarn...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D03D15/00D02G3/00D02H3/00D06B7/04D03D15/54

Inventor 刘林泉刘瑞金

Owner 刘林泉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com