Cashmere fabric assembly line and process

An assembly line and fabric technology, applied in the field of cashmere fabric assembly line and process, can solve the problems of skin damage of cashmere sweaters, affecting the skin-friendly nature of cashmere sweaters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

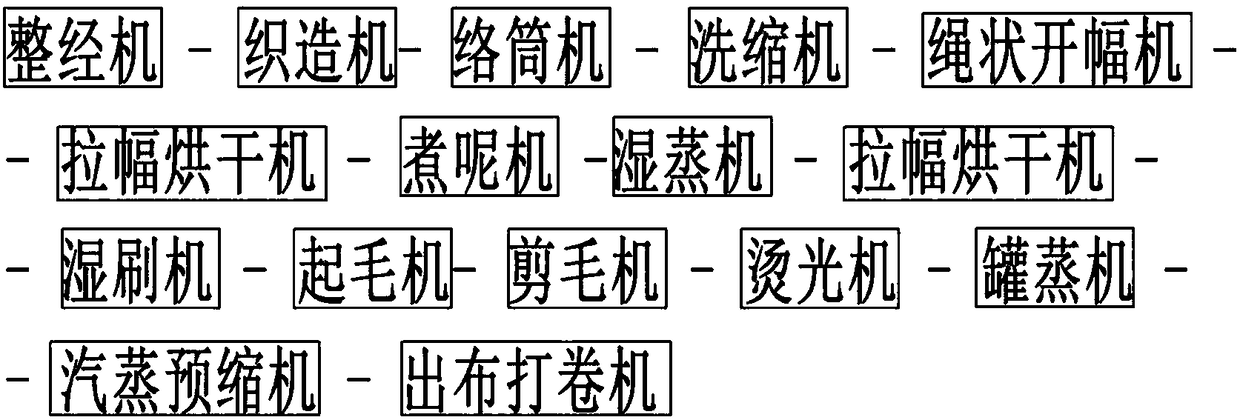

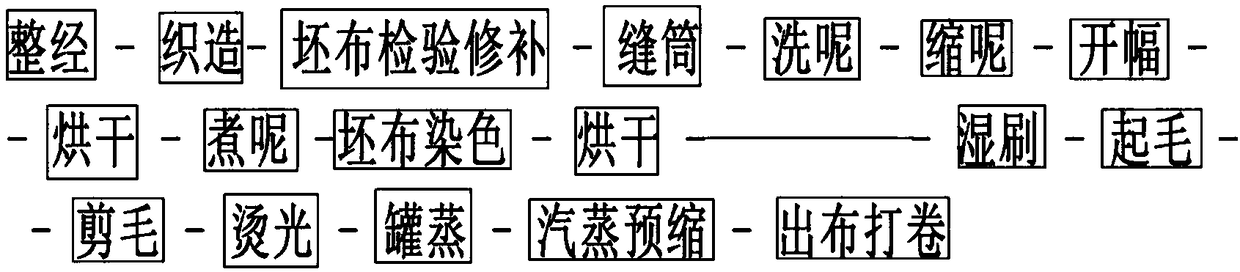

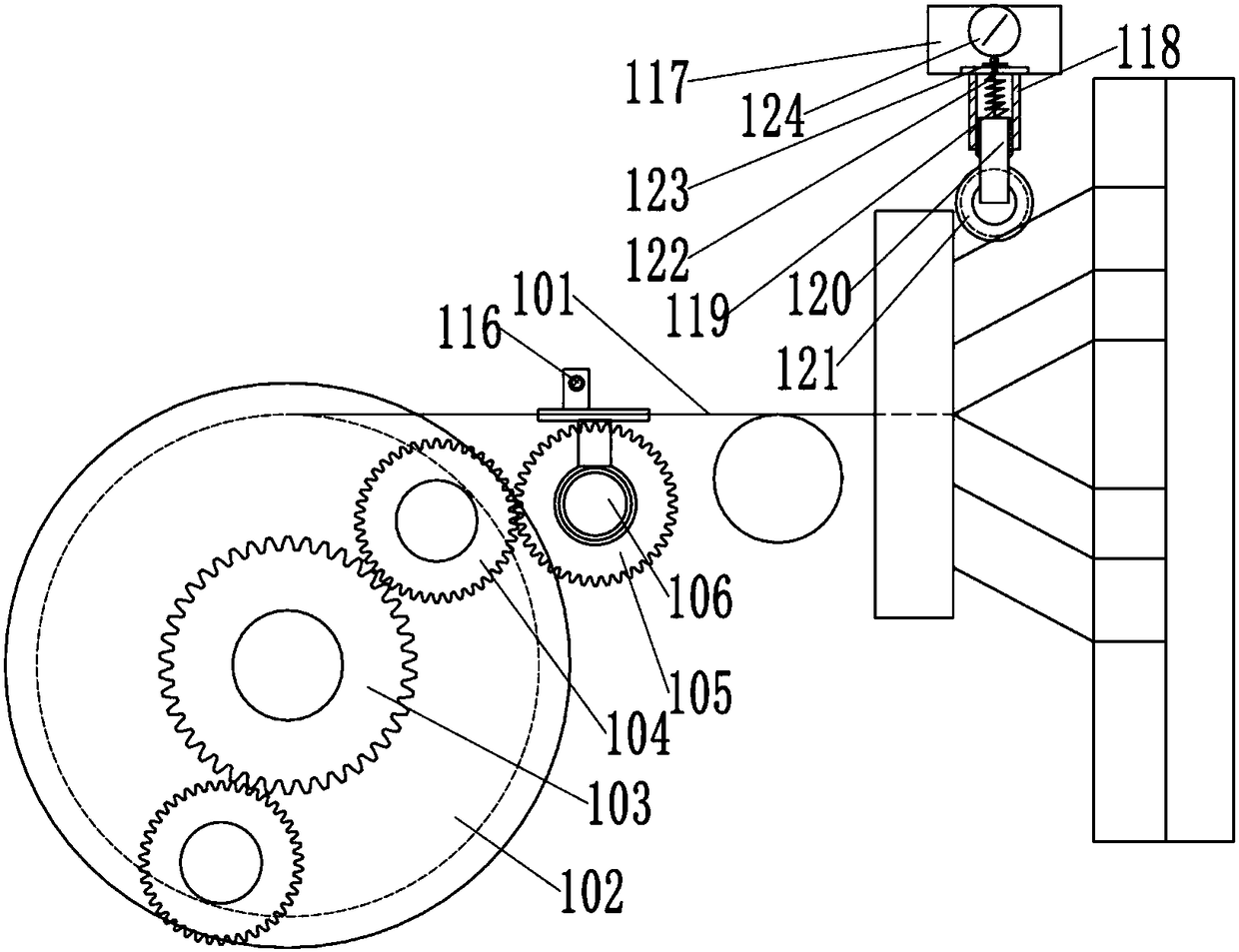

[0008] Such as Figure 1-14 , the cashmere fabric assembly line of the present embodiment, comprises sequentially connecting warping machine, weaving machine, bobbin winder, washing and shrinking machine, rope opening machine, tenter dryer, woolen cooking machine, wet steamer, tenter Drying machine, wet brushing machine, raising machine, shearing machine, ironing machine, pot steamer, steam pre-shrinking machine, and / or cloth coiling machine, etc. The weaving machine is the GA615A2-56 loom of Ningjin Lujia Textile Machinery Co., Ltd., the winding machine is the R6 / 48 winding machine of S.A.V.s.a.s.di CANTARELLO&C, and the rope opening machine is the YH912-1 of Shanghai Mike Control Engineering Co., Ltd. / 40-SK98023-1279.TMS-3000 Rope Open Width Machine, Stenter Dryer, Washing and Shrinking Machine are FOLATEX4C-166 Washing and Shrinking Combined Machine of Italian CIMI Company, Stenter Drying Machine is produced by Italian CORINO Company, and / or the ironing machine is the SM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com