Production technology of quick-dry terylene yarn-dyed seersucker fabric

A production process, seersucker technology, applied in the field of fabric weaving, can solve the problems of discomfort, fabric sticking, poor hygroscopicity, etc., and achieve the effects of improving poor skin affinity, avoiding yarn fluffing, and low fabric cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] 1. The mechanism of rapid moisture wicking:

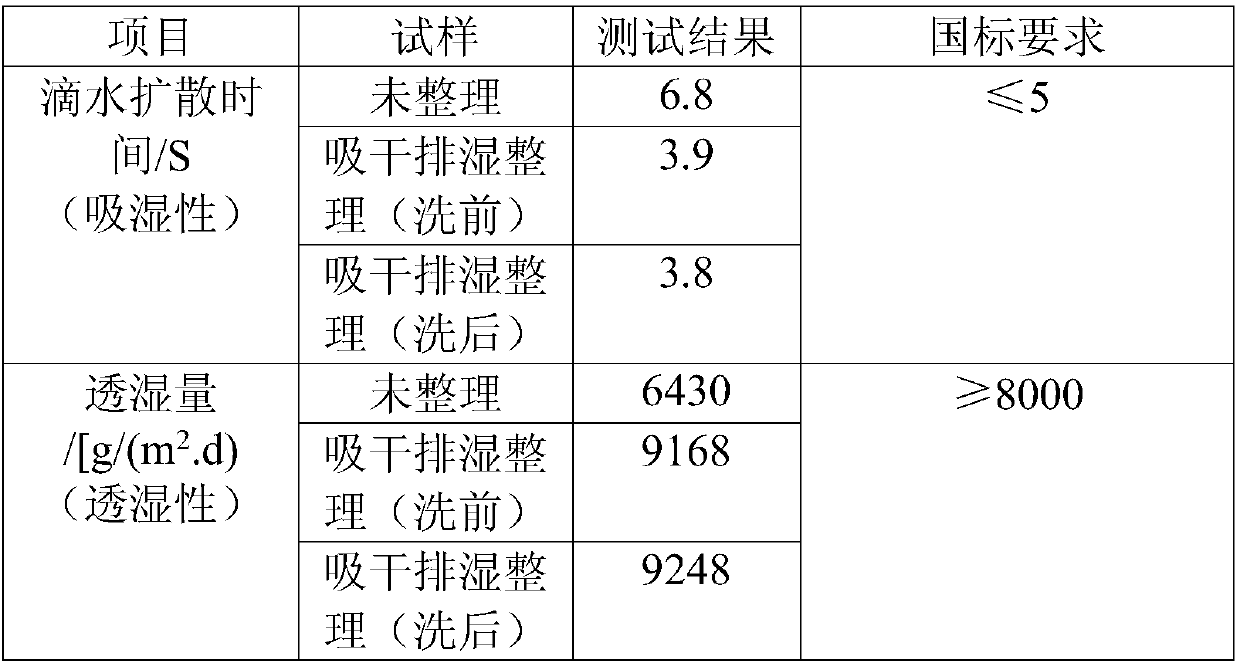

[0038]At present, the popular quick-drying fabrics in the market mainly have two formation mechanisms. One is to use functional fast-absorbing and moisture-wicking fibers, and other fibers with good moisture-absorbing properties to be blended and interwoven into fast-absorbing fabrics. Due to the high price and low output of functional fiber, it cannot fully meet people's needs at present. The second is to use ordinary fabrics for quick drying and finishing. That is, hydrophilic finishing is performed on the surface of the fabric. After the fabric is quick-drying, it can quickly absorb water. Sweat does not diffuse inside the fiber. The water is directly transferred to the outer layer of the fabric and evaporated to keep the inner layer of the fabric dry, that is, after the fabric absorbs water, It will no longer stick to human skin, improving the comfort of the fabric. Polyester-cotton yarn-dyed quick-drying fabric is to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com