Production method for super-low-twisted electronic grade glass fiber cloth

A technology of glass fiber cloth and production method, which is applied in fiber processing, textiles and papermaking, and warping machines, etc. It can solve the problems of yarn hairiness, loose single fiber arrangement, etc., and achieve high fabric density and yarn tension. Uniform, flat and crisp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

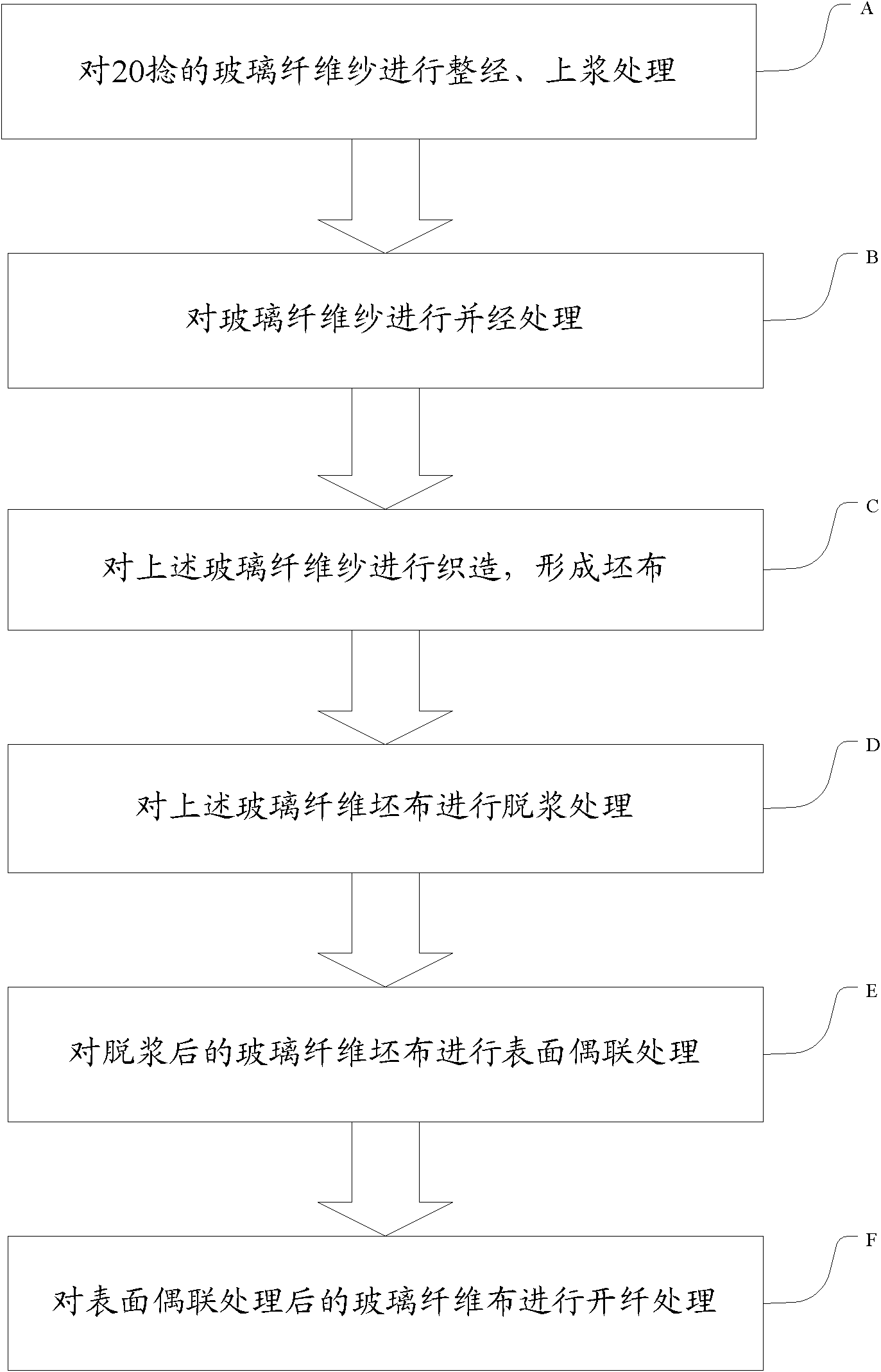

[0028] See figure 1 As shown, the present invention provides a kind of production method of ultra-low twist electronic grade glass fiber cloth, and it specifically comprises the following steps:

[0029] A. Wind the glass fiber yarn with a twist of 20 twists in parallel on the warp beam or weaving beam, and carry out its warping treatment through the warping machine, and immerse the 20 twist glass fiber yarn after warping treatment into modified PVA Carry out sizing treatment in the mold size, then press off the excess size, dry and divide the 20-twist glass fiber yarn, and finally roll it into a weaving shaft;

[0030] Among them, the surface of the 20-twisted glass fiber yarn after sizing treatment is attached with a layer of thin organic size protective film, which can ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com